3D Printed Stand for PiDP-11

640 views

Skip to first unread message

Mike Ferrara

Nov 11, 2018, 1:15:08 PM11/11/18

to [PiDP-11]

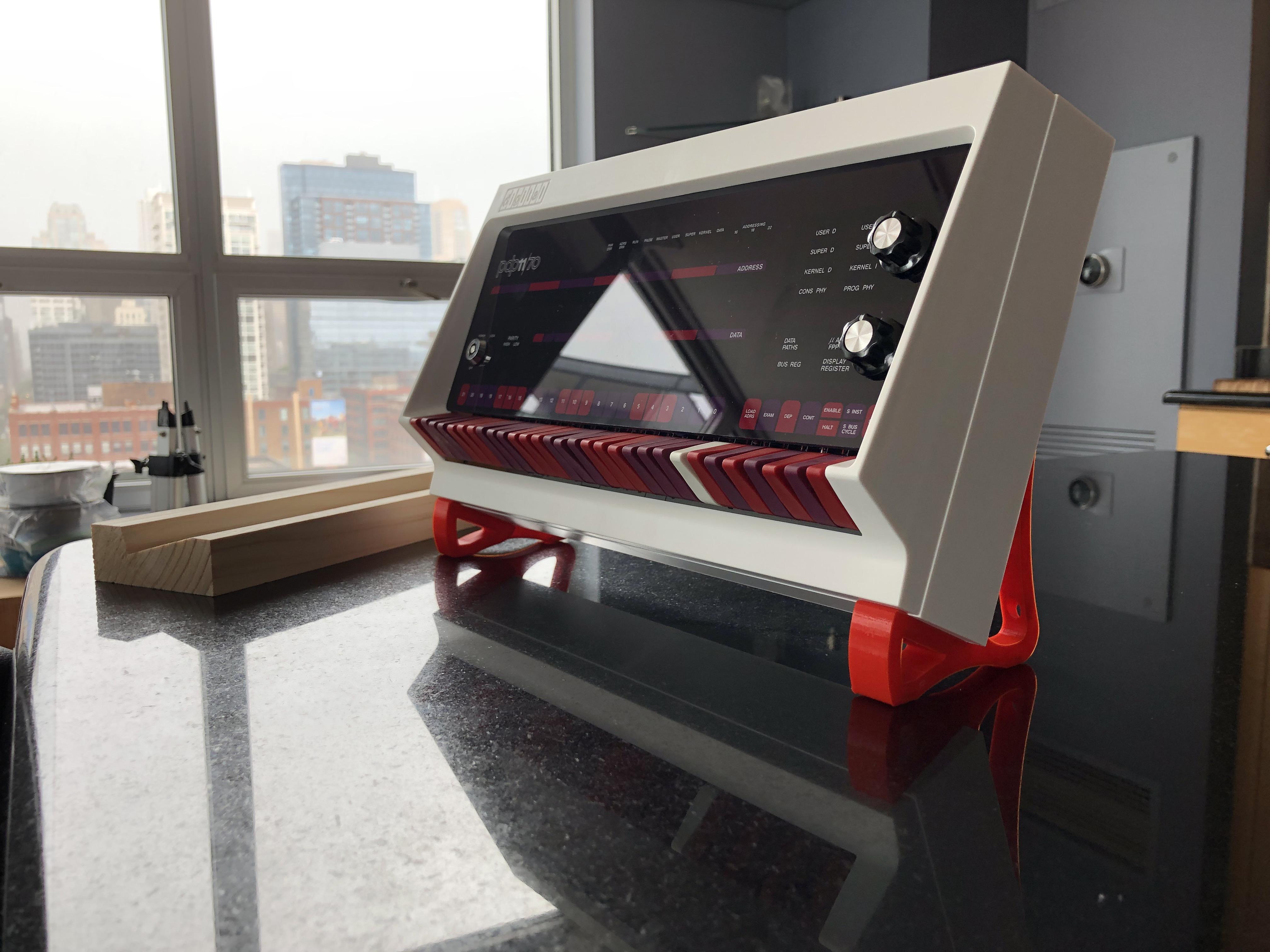

Hey folks, I made a simple 3D-Printed stand for the PiDP-11 that I kind-a like:

Fits in under two of the back screws. Should be fine with any material (I used some CPE HG100 because that was the best color match I had on hand). Use supports for the screw slot, and I printed with 3 perimeters. Enjoy!

-mike ferrara

Oscar Vermeulen

Nov 11, 2018, 2:34:07 PM11/11/18

to mike.r....@gmail.com, pid...@googlegroups.com

Mike,

Nice!

I spent a huge amount of time finding a good stand for the world's first Self-Toppling Desktop Computer (R). Most things I came up with would not allow toggling the switches without, well, toppling over the machine. The wooden stand was finally thought of my my local carpenter... it wedges the back of the case in the wood block for added resistance. Is your solution topple-resistant?

BTW - nobody ever does it, it seems, but the wooden stand looks quite nice when you either put a coat of varnish or wood stain on it.

It *really* matters a lot! So much so that said carpenter made a few for me to prove it. He sands round edges on the front side, wood-stains them - and all of a sudden they look museum grade. Or, at least, transformed into something chique. I recommend it! As nobody does it apparently, I've been thinking of having it done by default. But it adds rather a lot of cost... manual labour.

Kind regards

Oscar.

--

You received this message because you are subscribed to the Google Groups "[PiDP-11]" group.

To unsubscribe from this group and stop receiving emails from it, send an email to pidp-11+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/pidp-11/b32f98dd-0baf-44db-a107-62663a005395%40googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

Mike Ferrara

Nov 11, 2018, 4:25:30 PM11/11/18

to [PiDP-11]

So, this was just an attempt. I'm sure someone here will build on it and make something better. With my feet screwed in it's fairly stable, and stable enough to toggle. My next task is to finish the wood stand and make a final decision. Many thanks for the PiDP's ... I've got an 8 and a 11 and love them! Truly things of beauty!

-mike

Mike Ferrara

Nov 13, 2018, 11:08:01 PM11/13/18

to [PiDP-11]

I brought my PiDP-11 into work to show off to another old timer (sadly 99% of my co-workers have literally no clue what they're looking at ... and we're designing chips!) ... Anyway, back to the point at hand ... Oscar asked if the feet I 3D-printed were stable under toggling, and my experience so far is yes; reasonably stable. Part of that stability comes from the fact that they're screwed in.

I encourage someone else to try printing them up and give a report on stability.

-mikef

Neil Higgins

Nov 14, 2018, 3:55:47 AM11/14/18

to [PiDP-11]

Hi Mike. I am a 3d-printing tyro. I have just taken delivery of a printer but haven’t got beyond opening the box yet. I’m intrigued by the shape of your stand: Why doesn’t the thin projection at the back just ... ah ... break off? Perhaps I underestimate the strength of the material - it looks (a bit) like acrylic, but might be something less brittle (?)

steve...@gmail.com

Nov 14, 2018, 6:57:45 AM11/14/18

to [PiDP-11]

MN Greer posted OpenScan and STL files for a 3-d printed stand he designed for the PiDP-8/i. See the "PiDP Photo Thread: show us your setups!" thread, his posting is dated 22-May. It's a really nice stand, a friend with a 3-d printer made some for my PiDP-8s.

I am wondering if you could modify his design to make something similar for the PiDP-11/70. It should be a lot more stable and a lot sturdier than what you are showing.

Cheers,

-- steve

Mike Ferrara

Nov 14, 2018, 1:22:48 PM11/14/18

to [PiDP-11]

On Wednesday, November 14, 2018 at 12:55:47 AM UTC-8, Neil Higgins wrote:

Hi Mike. I am a 3d-printing tyro. I have just taken delivery of a printer but haven’t got beyond opening the box yet. I’m intrigued by the shape of your stand: Why doesn’t the thin projection at the back just ... ah ... break off? Perhaps I underestimate the strength of the material - it looks (a bit) like acrylic, but might be something less brittle (?)

Hey Neil ... You'd be surprised how strong 3D printed plastics can be. However, I've have a few points to make since you'll be printing soon:

1) The material isn't isotropic, it's layered, and usually the weakest part is the layer-to-layer adhesion. This means it's really difficult, if not impossible to calculate strength ahead of time (like with a finite-element tool)

2) In this part I printed it lying down so breaking at the laminations would just make the foot narrower, so the strength/weakness is working in the right direction.

3) None of that really matters with this part, it's plenty strong, AND instead of breaking, the PiDP would always just tip over. My first versions when I was trimming the angle used a 2mm thick back. It was plenty strong enough. In my final design, I beefed it up to 3mm for no good reason.

4) The material I used was Filamentum HG100 CPE only because that was the closest color match on hand. I'd have normally just printed this with PLA. For mechanical parts I prefer PETG, and for stuff that's not demanding, I'll use PLA. The CPE is pretty strong and tough, but it prints stringy. Part strength is mostly determined by design, in the end.

5) This foot isn't perfect, but it's good enough for me. You might consider extending the back to reduct tippiness further. Luckily, the switches are mounted low, so throwing them doesn't generate a large tipping moment.

Enjoy your new printer. Start with PLA, and once you're comfortable with the process, get a good spool of PETG. Always get your first layer right, and things will tend to go smoothly. They're really cool devices and change the way you solve problems.

-mikef

1) The material isn't isotropic, it's layered, and usually the weakest part is the layer-to-layer adhesion. This means it's really difficult, if not impossible to calculate strength ahead of time (like with a finite-element tool)

2) In this part I printed it lying down so breaking at the laminations would just make the foot narrower, so the strength/weakness is working in the right direction.

3) None of that really matters with this part, it's plenty strong, AND instead of breaking, the PiDP would always just tip over. My first versions when I was trimming the angle used a 2mm thick back. It was plenty strong enough. In my final design, I beefed it up to 3mm for no good reason.

4) The material I used was Filamentum HG100 CPE only because that was the closest color match on hand. I'd have normally just printed this with PLA. For mechanical parts I prefer PETG, and for stuff that's not demanding, I'll use PLA. The CPE is pretty strong and tough, but it prints stringy. Part strength is mostly determined by design, in the end.

5) This foot isn't perfect, but it's good enough for me. You might consider extending the back to reduct tippiness further. Luckily, the switches are mounted low, so throwing them doesn't generate a large tipping moment.

Enjoy your new printer. Start with PLA, and once you're comfortable with the process, get a good spool of PETG. Always get your first layer right, and things will tend to go smoothly. They're really cool devices and change the way you solve problems.

-mikef

Mike Ferrara

Nov 14, 2018, 1:23:04 PM11/14/18

to [PiDP-11]

Mike Ferrara

Nov 14, 2018, 1:28:59 PM11/14/18

to [PiDP-11]

Steve ... I'm sure it can be done. I've got a copy of the openSCAD design and that's one of the first things that popped in my head when I was thinking about a 3D printed stand. I literally threw this design together as a proof of concept and to capture Oscar's angles in FreeCAD. If I was modifying the PiDP8 stand, I might still make use of the back screws to eliminate a cross-piece.

-mikef

-mikef

Neil Higgins

Nov 14, 2018, 7:21:22 PM11/14/18

to [PiDP-11]

Hi Mike. Thank you for taking the time to explain. I purchased an entry-level printer which is purportedly “PLA only”. Looking at the temperature guide, I might eventually be able to experiment with CPE (a relatively new material, I gather). Cheers, Neil

Alex King

May 21, 2019, 6:01:57 PM5/21/19

to pid...@googlegroups.com

Hi All,

I didn't think to look for a stand alternative to the supplied wooden block, and ended up having fun making my own. It would have been a lot faster if I'd just looked and used Mike's.

Anyway, this new one is https://www.thingiverse.com/thing:3641261 if anyone is interested. It prints great with PLA.

It does a similar dealy with the lower screws in the backplate being used to keep everything in place. I also added recesses for little rubber feet which seem to keep the PiDP-11 really stable with toggling.

Alex

Jeff Thieleke

May 21, 2019, 8:53:08 PM5/21/19

to [PiDP-11]

I found this independently on Thingiverse, was super impressed, made a pair in both black and white, and left a comment. Then I saw this thread revived today because of Alex King's design. Nothing more to say other than thanking you again for sharing a well designed and practical print!

Jeff Thieleke

May 21, 2019, 8:59:20 PM5/21/19

to [PiDP-11]

Thank you for designing this! I'm currently alternating between Mike's design and my beginner-level staining job on the wooden stand. As I'm typing, my PiDP11 (via Octoprint) is managing a print of your design. I'm looking forward to trying it out after I print out it's mate, but I'll just say that the sound my stepper motors make while going over that back curve is pretty sexy...

Alex King

May 22, 2019, 11:08:24 PM5/22/19

to [PiDP-11]

Haha! That's very kind of you to post, thank you Jeff!

osuvman

May 23, 2019, 5:45:15 PM5/23/19

to [PiDP-11]

On Tuesday, May 21, 2019 at 6:01:57 PM UTC-4, Alex King wrote:.

Anyway, this new one is https://www.thingiverse.com/thing:3641261 if anyone is interested. It prints great with PLA.

What's the spacer disk file in the .zip file for?

Brian Welland

May 24, 2019, 2:06:07 AM5/24/19

to [PiDP-11]

The spacer is an option for reducing the depth of the feet recesses if required - just depends how high your feet rubbers are.

Jeff Thieleke

May 25, 2019, 8:28:09 PM5/25/19

to [PiDP-11]

I printed out a pair of your design and am impressed in general (especially how you designed the back support arch thing). Just a couple of suggestions:

1. I think the base needs to be wider, more like Mike's design. Maybe if you have the corrected sized rubber feet it isn't an issue, but with the ones I had on hand it seemed a little wobblier side-to-side. There is also just a "beefier" look to Mike's design which I prefer.

2. I printed with supports, which was probably a mistake, but it made the screwdriver access hole (on the curvey back part) sealed off. This made it hard to install with the screwdriver I happened to have handy. Following along with point #1, if the whole thing was a little wider, I think there would be enough room for most people's hobbyist screwdrivers to easily access through the back into the front part.

And just to be clear, I have the deepest respect for anyone who puts their work out there to be used and critiqued, so please accept this unsolicited advice in the best way possible!

Mike Ferrara

May 26, 2019, 3:11:47 PM5/26/19

to [PiDP-11]

One thing to note about the two designs. I tried to replicate Oscar's "tilt" angle, and it looks like Alex took it a little further; probably to make it more comfortable to work at a desk. The curvy back adds visual interest, but probably little mechanical support; however its extended foot probably is an improvement in stability. The fun thing about 3D printing is how it changes the way you solve problems. My design is very utilitarian ... Alex's is much more professional looking ... it gives you all a look into our minds ;-).

-mikef

Geoffrey McDermott

May 26, 2019, 5:22:50 PM5/26/19

to [PiDP-11]

I'm new to 3d printing(my printer arrived Thursday), and after beating my head against the proverbial wall, I'm able to make decent prints.....YEA!!!

Not knowing what to purchase for filament, I decided that ABS was stronger than PLA, so I bought a roll of CLEAR filament. Besides the fact that after it's extruded it is actually white, I'm having sever problems with the brittleness of the results. No amount of advice from the WEB has helped, so be warned.......ABS might sound good, but it can be quite brittle.

The 'small' stands for the PiDP11 work well, since their design doesn't require any real flexibility.........I've ordered some PLA filament, and will try the other version after EBAY delivers the order.

osuvman

May 27, 2019, 7:39:18 AM5/27/19

to [PiDP-11]

On Saturday, May 25, 2019 at 8:28:09 PM UTC-4, Jeff Thieleke wrote:

I printed out a pair of your design and am impressed in general (especially how you designed the back support arch thing).

The design is asymmetric, are you supposed to make a mirror image for the other bracket?

Jeff Thieleke

May 30, 2019, 8:05:19 PM5/30/19

to [PiDP-11]

Yes, I think you need to mirror the layout so the rubber foot inserts are on the outside, if you're looking at it from the front. It works if you don't mirror but you'll notice that the right part is offset to the interior of the PiDP-11 if you don't.

Alex King

Jun 5, 2019, 1:52:02 PM6/5/19

to [PiDP-11]

Do you guys think I should upload left and right hand brackets, rather than leaving it to the user to mirror?

Geoffrey McDermott

Jun 5, 2019, 6:13:39 PM6/5/19

to pid...@googlegroups.com

> --

> You received this message because you are subscribed to the Google

> Groups "[PiDP-11]" group.

> To unsubscribe from this group and stop receiving emails from it, send

> an email to pidp-11+u...@googlegroups.com

> <mailto:pidp-11+u...@googlegroups.com>.

> You received this message because you are subscribed to the Google

> Groups "[PiDP-11]" group.

> To unsubscribe from this group and stop receiving emails from it, send

> an email to pidp-11+u...@googlegroups.com

> To view this discussion on the web visit

> https://groups.google.com/d/msgid/pidp-11/265ac01c-7af1-4105-972c-5929d3e954ab%40googlegroups.com

> <https://groups.google.com/d/msgid/pidp-11/265ac01c-7af1-4105-972c-5929d3e954ab%40googlegroups.com?utm_medium=email&utm_source=footer>.

Absolutely, or change the design to be symmetrical.......make it simple.

Reply all

Reply to author

Forward

0 new messages