Re: [MakerSpace] accurately drilling holes in edges of a 1/2" aluminum plate

8 views

Skip to first unread message

Andrew McIntosh

Aug 19, 2017, 3:00:13 PM8/19/17

to milwaukee...@googlegroups.com

Hey Mark,

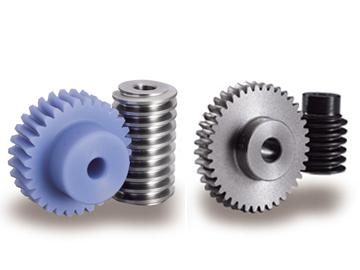

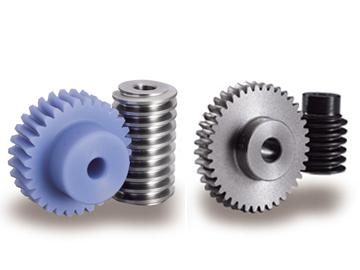

Wondering if you could utilize a worm gear system like this below to fine tune your angle. im thinking you could easily 3D print something like this.

you could create a pin that runs parallel to the bottom edge of the aluminum plate the "scope" is mounted to with the "worm" like below. Then attach a small knob to the end of the "worm gear" (purple below). As you turn, it will transfer motion perpendicularly allowing the "scope mount plate" to rotate about that axis of the pin.

If you need help modeling let me know. i use 3D modeling software almost daily at work. McMaster-Carr provides these 3D .step files that you could download and model a base around.

On Sat, Aug 19, 2017 at 9:20 AM, the_digital_dentist <mark.r...@gmail.com> wrote:

I am trying to design an equatorial wedge for a small telescope. It's just two plates, about 6" wide, that are hinged together with a screw to adjust the angle between the plates (similar to this). The vast majority of designs I have seen use piano hinges and plywood which bothers me, so I'm trying to design something more solid, using 1/4" or 1/2" cast aluminum tooling plate. I'm thinking of using a ball bearing door hinge, but if someone has a better idea, I'm all ears. The angle between the plates is set to 90 degrees minus the latitude where the scope is located, about 47 degrees in the Milwaukee area, and needs to be finely adjustable, over a range of maybe 40-70 degrees. The hinge needs to be free of play, and alignment should be very accurate.--This is a crude illustration of the wedge showing the range of motion required of the hinge (40-70 degrees). The blue is the top of the tripod, the green is the base of the telescope, and the purple are aluminum pieces, probably cast tooling plate.Anyone have a spare ball bearing door hinge laying around for sale or trade?Anyone have any brilliant ideas to make this as simple and solid as possible?

---

You received this message because you are subscribed to the Google Groups "milwaukeemakerspace" group.

To unsubscribe from this group and stop receiving emails from it, send an email to milwaukeemakerspace+unsub...@googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

Reply all

Reply to author

Forward

0 new messages