Help! - I need some nylon gears duplicated or replaced...

22 views

Skip to first unread message

Nic Hume

Jan 29, 2016, 1:33:55 AM1/29/16

to makerspaceca

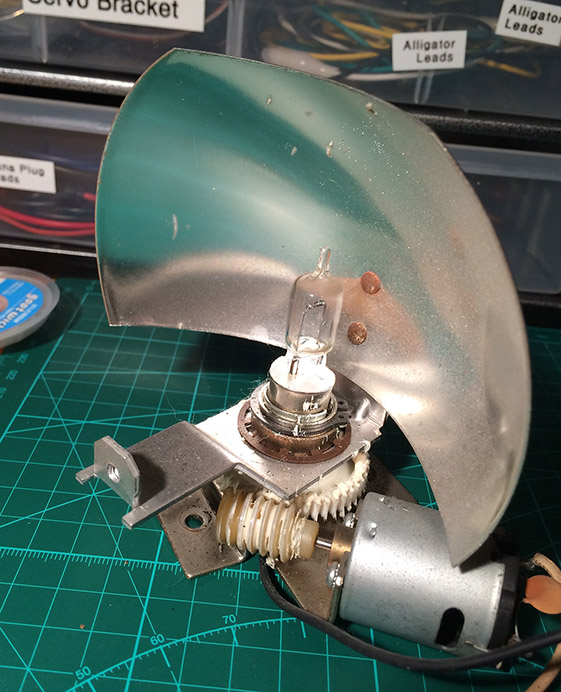

I'm working on restoring an old set of ambulance emergency lights as a present for a friend. We're talking 1970/80s-vintage, with the old rotating reflectors around a halogen bulb.

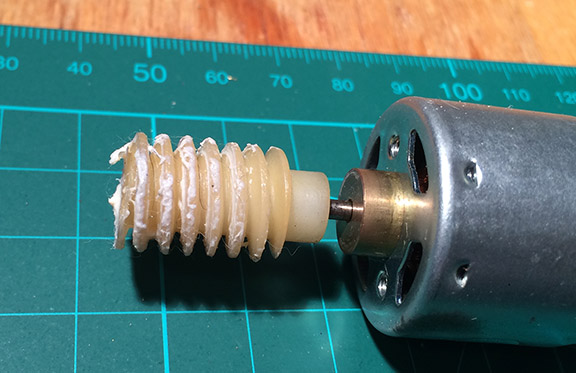

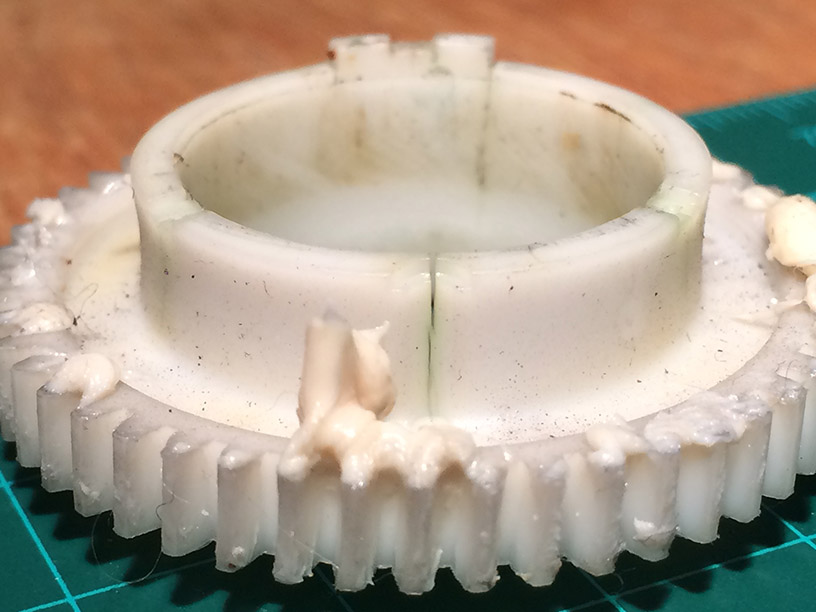

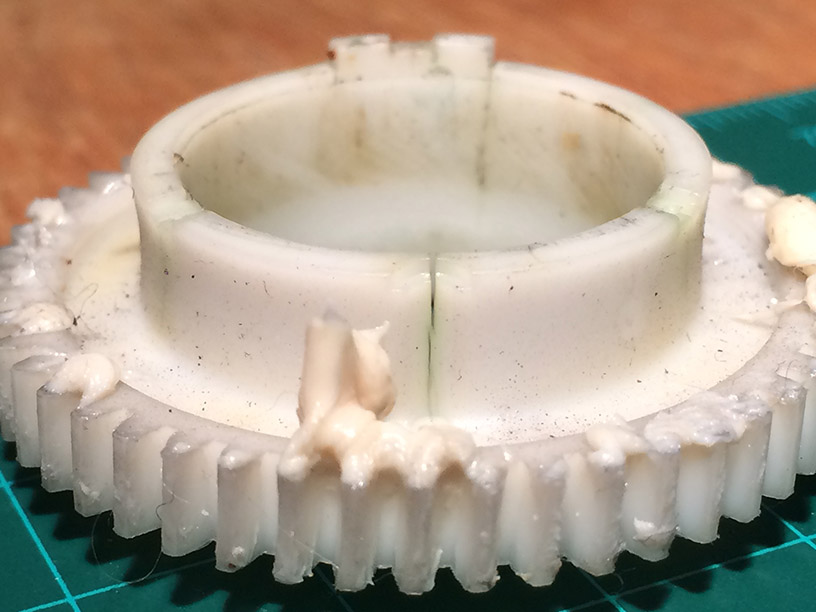

The nylon (I think?) gears that drive the rotating reflector are old and cracked, and some of the teeth are worn down. They blatantly need to be replaced.

I suspect the worm-gear on the motor shaft should also be replaced, which may open up options a bit, as I suppose I can more readily find matching pairs of gears/worm-gears than finding a gear to match the worm unit... Of course, the gear-wheel itself has a couple of mating flanges on it, that I would have to fabricate, and I'm not sure how I'd go about that ...

Is this something that can be 3D-scanned and then 3d-printed? Or? Are there repositories of pre-designed 3d-printable gears on the internet? Can a 3d-printed part take the abuse of being used like this? (The motor draws about 1.0 Amps at 12V, so it's not huge, but not insignificant amount of force being placed on the gears either.) ... IF I'm better off trying to get these gears reproduced commercially, can anyone recommend a fabricator?

I don't want to say I have an "unlimited" budget, but I'm willing to drop up to a couple hundred bucks on the project... (Sentimental value to the friend that it is for...)

I've attached a few pics of the gear in question to give a sense of scale, and the existing damage, as well as pics of the whole assembly

Assuming I replace *ALL* the gears in question, I would need 4 units of each type (gear wheel and worm-gear)...

Thoughts? Help?

-N

A S

Jan 29, 2016, 2:08:55 AM1/29/16

to makers...@googlegroups.com

Given your budget, commercial fabrication may not be possible (I don't

know). You may have to invest significant time in lieu of budget.

1. Vince can cast metal or plastic items from models or originals, it's

worth asking about his rates.

2. You could print new gears on the 3D printer, given a 3D-model file. I

hear it's easier to use than our previous printers.

You might be able to find a gear-model-generating program or website

that could generate a gear similar to yours, then you could modify that

model as desired.

Or you could design your gear from scratch, or ask for quotes from MS

members for 3D modelling. Such an approach might go faster if you have,

or are willing to break, a gear in half.

I think 3D scanning would be more trouble, I doubt it would come out as

neat as a from-scratch 3D model. But I welcome being proved wrong :)

3. Once you have a nice model, you can print it on the 3D printer, using

a low interior fill percentage. That gets you a gear that prints fast

but won't stand up to normal use, however you can check this for fit in

your final unit.

Once it fits, you can reprint it on the 3D printer using 100% interior

fill which will take a long time to print but will be strong. There's a

solid black-plastic gear (about 4" diameter) on the shelves above the 3D

printer if you want to see how strong 3D printed objects can get.

4. Have you tried ebay? Would any gear with the same diameter, width and

teeth do?

know). You may have to invest significant time in lieu of budget.

1. Vince can cast metal or plastic items from models or originals, it's

worth asking about his rates.

2. You could print new gears on the 3D printer, given a 3D-model file. I

hear it's easier to use than our previous printers.

You might be able to find a gear-model-generating program or website

that could generate a gear similar to yours, then you could modify that

model as desired.

Or you could design your gear from scratch, or ask for quotes from MS

members for 3D modelling. Such an approach might go faster if you have,

or are willing to break, a gear in half.

I think 3D scanning would be more trouble, I doubt it would come out as

neat as a from-scratch 3D model. But I welcome being proved wrong :)

3. Once you have a nice model, you can print it on the 3D printer, using

a low interior fill percentage. That gets you a gear that prints fast

but won't stand up to normal use, however you can check this for fit in

your final unit.

Once it fits, you can reprint it on the 3D printer using 100% interior

fill which will take a long time to print but will be strong. There's a

solid black-plastic gear (about 4" diameter) on the shelves above the 3D

printer if you want to see how strong 3D printed objects can get.

4. Have you tried ebay? Would any gear with the same diameter, width and

teeth do?

Eric Davies

Jan 29, 2016, 2:17:06 AM1/29/16

to makers...@googlegroups.com

Would this be relevent? http://www.thingiverse.com/thing:8821

--

You received this message because you are subscribed to the Google Groups "makerspaceca" group.

To unsubscribe from this group and stop receiving emails from it, send an email to makerspaceca...@googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

Eric Davies

Kc Petersen

Jan 29, 2016, 5:55:37 AM1/29/16

to makerspaceca

3d printing would be your most cost effective route. As far as the model, inventor and solid works both make it very easy to model gears. I'm sure a couple hours with the gears and a set of calipers i could get you a near identical part model. then its just a matter of a few hours printing. You also have the model file and if it doesn't last as long as the original you can print a new one.

Mark

Jan 29, 2016, 9:58:11 AM1/29/16

to makers...@googlegroups.com

That's a perfect job for the 3D printer! Looks like fun.

--

You received this message because you are subscribed to the Google Groups "makerspaceca" group.

To unsubscribe from this group and stop receiving emails from it, send an email to makerspaceca...@googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

Craig Carmichael

Jan 31, 2016, 1:29:52 PM1/31/16

to makers...@googlegroups.com

There are 3-D printer gear designs at thingiverse.com . I don't know

if you'll find what you need. If there's some close, maybe in

openscad, you might be able to modify them.

Craig

=====

>>Inline image 5

>>

>>Inline image 6

>>

>>Inline image 7

>>

>>Inline image 8

>>[E] Nic....@gmail.com <mailto:Nic....@gmail.com>

>>

if you'll find what you need. If there's some close, maybe in

openscad, you might be able to modify them.

Craig

=====

>>

>>Inline image 6

>>

>>Inline image 7

>>

>>Inline image 8

>>[E] Nic....@gmail.com <mailto:Nic....@gmail.com>

>>

Nic Hume

Jan 31, 2016, 4:24:39 PM1/31/16

to makerspaceca

Thanks for all the great ideas guys! I have a couple of leads I'm following up now, but may come back and beg for more advice if they don't pan out! :)

On a semi-related note, if you look at the last picture I attached in my original email, you'll notice some white "gunk" on the reflector. As best I can tell, that is grease from the motor gears that splattered up, and is now baked onto the reflector... The reflector appears to be chromed aluminum (I'm about 95% sure). Does anyone have ideas on how to get it off without mucking up the chrome job?

-N

On Sun, Jan 31, 2016 at 10:34 AM, Craig Carmichael <cr...@saers.com> wrote:

There are 3-D printer gear designs at thingiverse.com . I don't know if you'll find what you need. If there's some close, maybe in openscad, you might be able to modify them.

Craig

=====

That's a perfect job for the 3D printer! Looks like fun.

On 28/01/2016 10:33 PM, Nic Hume wrote:

I'm working on restoring an old set of ambulance emergency lights as a present for a friend. We're talking 1970/80s-vintage, with the old rotating reflectors around a halogen bulb.

The nylon (I think?) gears that drive the rotating reflector are old and cracked, and some of the teeth are worn down. They blatantly need to be replaced.

I suspect the worm-gear on the motor shaft should also be replaced, which may open up options a bit, as I suppose I can more readily find matching pairs of gears/worm-gears than finding a gear to match the worm unit... Of course, the gear-wheel itself has a couple of mating flanges on it, that I would have to fabricate, and I'm not sure how I'd go about that ...

Is this something that can be 3D-scanned and then 3d-printed? Or? Are there repositories of pre-designed 3d-printable gears on the internet? Can a 3d-printed part take the abuse of being used like this? (The motor draws about 1.0 Amps at 12V, so it's not huge, but not insignificant amount of force being placed on the gears either.) ... IF I'm better off trying to get these gears reproduced commercially, can anyone recommend a fabricator?

I don't want to say I have an "unlimited" budget, but I'm willing to drop up to a couple hundred bucks on the project... (Sentimental value to the friend that it is for...)

I've attached a few pics of the gear in question to give a sense of scale, and the existing damage, as well as pics of the whole assembly

Assuming I replace *ALL* the gears in question, I would need 4 units of each type (gear wheel and worm-gear)...

Thoughts? Help?

-N

Inline image 5

Inline image 6

Inline image 7

Inline image 8

Inline image 9

--

Nic Hume

[C] 250.661.0822

[E] Nic....@gmail.com <mailto:Nic....@gmail.com>

--

You received this message because you are subscribed to the Google Groups "makerspaceca" group.

To unsubscribe from this group and stop receiving emails from it, send an email to makerspaceca...@googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

Kc Petersen

Jan 31, 2016, 4:35:36 PM1/31/16

to makerspaceca

I use sos pads on the chrome for my harley. Works great.

Reply all

Reply to author

Forward

0 new messages