CoreXY belt path - new twist? (pun intended)

makertr...@gmail.com

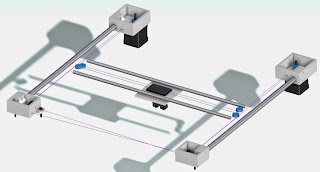

Note: This only applies if you are using CoreXY with the belts intersecting.

I've always had a challenge keeping the belts from rubbing eachother at the intersection in a corexy configuration. Adding spacers and washers galore did the trick, but adding more of these seemed to complicate matters. Then, I discovered recently that if you flip the gt2 belts at the intersection, they avoid eachother altogether. Specifically, at the intersection, the belts smooths sides are now facing eachother. I can use less washers and spacers now and the belt travel is quieter.

Thanks, Chris

iquizzle

makertr...@gmail.com

I highly recommend going CoreXY since it removes the racking problem that is common with non-crossed belt hbots.

Dealing with the belt rubbing was the part that I dreaded with CoreXY. Now that this has been solved with the belt twist at the intersection, I find the setup simple.

iquizzle

makertr...@gmail.com

Rupin Chheda

Chris Welch

Ryan Carlyle

Chris Welch

Ryan Carlyle

What are you using for a motor capstan pulley?

Chris Welch

Ryan Carlyle

Ryan Carlyle

http://www.pcwirelines.co.uk/machine.php?id_pcl=37

These can develop unbelievable line pull but you'd have to lathe it up yourself.

Other option I was thinking is a standard curved shipboard capstan profile like this:

http://www.qrbiz.com/product/1157829/10-Ton-Electric-Capstan.html

Problem with these (and most designs) is that the line has to slip sideways when the wraps travel to the end of the pulley.

Ryan Carlyle

Gotta get a straight CoreXY bot built first though.

Ryan Carlyle

Elliot Foster

iquizzle

Elliot

--

You received this message because you are subscribed to the Google Groups "H-bot and CoreXY 3d printers" group.

To unsubscribe from this group and stop receiving emails from it, send an email to h-bot-and-corexy-3d-...@googlegroups.com.

Visit this group at http://groups.google.com/group/h-bot-and-corexy-3d-printers.

Ryan Carlyle

Elliot

the diameter, since really you're looking for a surface area (contact

patch). Five wraps around a pin/needle wouldn't give you much grip,

but one wrap around a wine barrel would.

I can't seem to find it, but someone experimented with a

large-diameter single wrap pulley drive. I can't remember what the

results were, but the steps/mm would be terrible, and the torque

required would also be substantial (I would assume.)

On Sun, May 4, 2014 at 8:48 PM, Ryan Carlyle <temp...@gmail.com> wrote:

> Rule of thumb for reel design is that you need 5 wraps on a spool for friction to prevent any line tension from reaching the termination. So I think 5x360=1800 degrees of line contact would be a safe slip-free upper bound. For a non-crossed arrangement, that's 10 half-wraps on the drive pulley.

>

Elliot

https://www.youtube.com/watch?v=_e7yy9u6QmA

Not condoning this design, but I think it's interesting.

Ryan Carlyle

> To unsubscribe from this group and stop receiving emails from it, send an email to h-bot-and-corexy-3d-printers+unsub...@googlegroups.com.

Chris Welch

Would something like this work? (I only drew one side)

The idea is that the large wheel will only rotate about 350deg, pulling the cable the distance required.

This way, you do not need to worry about the cable walking around the pulley and there is no slippage, as the cable is secured to the pulley.

No mechanical advantage is lost and no backlash is introduced.

The downside being that the wheel takes up more space and adds a little more rotational mass.

Thoughts? (before I go any further with this!)

iquizzle

Ryan Carlyle

Chris Welch

On Saturday, May 3, 2014 5:18:17 PM UTC-7, Ryan Carlyle wrote:

I like this:

http://3dprinterhell.blogspot.com/2013/06/a-better-filament-drive.html?m=1