CNC Router project

48 views

Skip to first unread message

Paul Bonser

Feb 22, 2015, 11:01:32 PM2/22/15

to atxhs-...@googlegroups.com

I have a project I need to complete in the next week or two which will

require use of the big CNC router. I know it's just barely gotten up

and running, but I am hoping that this can be a bit of a test project

for it to help us learn the things that need to be taught and how to

do this particular type of project.

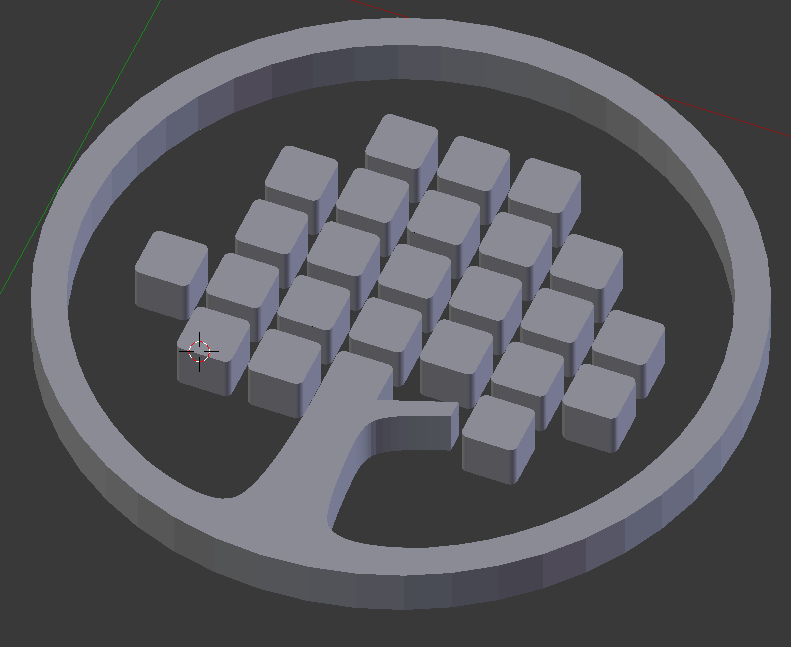

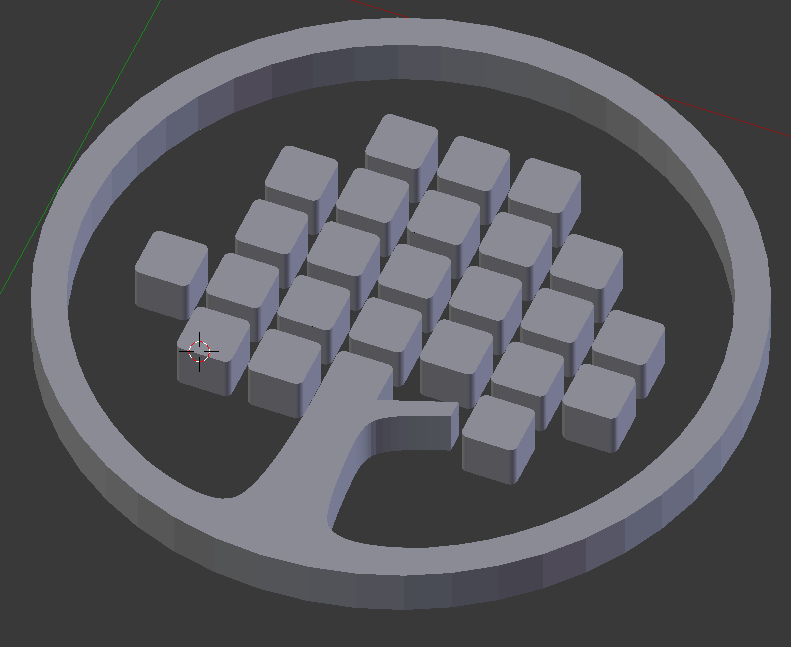

It's going to be a 5 foot diameter circular sign hanging at an event

during SXSW and the basic design is that it will be two layers of

plywood, one with a logo carved partway into it and another with the

same logo cut completely out of it and then inset into the first

piece.

In theory it should be a pretty simple job since it's just a 2D design

cut twice, once inside the lines and once outside the lines. There

will be a couple of places which will probably require finishing the

points with a handsaw since there are sharp corners.

Danny, what do we need to do to get started on this? I can meet you at

the space any evening this week to get going on this. I'm currently

planning on picking up the plywood from Austin Fine Lumber on Tuesday,

but would also be interested in running some smaller scale test cuts

before trying it on the full-size wood.

--

Paul Bonser | http://probablyprogramming.com | @pib

require use of the big CNC router. I know it's just barely gotten up

and running, but I am hoping that this can be a bit of a test project

for it to help us learn the things that need to be taught and how to

do this particular type of project.

It's going to be a 5 foot diameter circular sign hanging at an event

during SXSW and the basic design is that it will be two layers of

plywood, one with a logo carved partway into it and another with the

same logo cut completely out of it and then inset into the first

piece.

In theory it should be a pretty simple job since it's just a 2D design

cut twice, once inside the lines and once outside the lines. There

will be a couple of places which will probably require finishing the

points with a handsaw since there are sharp corners.

Danny, what do we need to do to get started on this? I can meet you at

the space any evening this week to get going on this. I'm currently

planning on picking up the plywood from Austin Fine Lumber on Tuesday,

but would also be interested in running some smaller scale test cuts

before trying it on the full-size wood.

--

Paul Bonser | http://probablyprogramming.com | @pib

Danny Miller

Feb 23, 2015, 1:14:34 AM2/23/15

to atxhs-...@googlegroups.com

Yeah, it's behaving better now.

Does it have to be exactly 5ft? Going all the way to exactly the 5ft

width is a bit problematic with the width of the dust shoe getting into

the rail clearances. It can do it without the shoe, but then, lotta

wood to clean up.

First off email me the design so I can play with the G-code export and

see how to make it work.

Danny

Does it have to be exactly 5ft? Going all the way to exactly the 5ft

width is a bit problematic with the width of the dust shoe getting into

the rail clearances. It can do it without the shoe, but then, lotta

wood to clean up.

First off email me the design so I can play with the G-code export and

see how to make it work.

Danny

Paul Bonser

Feb 23, 2015, 11:04:56 AM2/23/15

to atxhs-...@googlegroups.com

No, it doesn't have to be exactly 5 feet, but ideally as close as

possible. What size could we get with the dust shoe on? Something like

5.5 feet?

I've attached an Inkscape-friendly SVG of the logo that will be made

into the sign. You can see on the tree-trunk the parts that have the

sharp corners I mentioned. We could round those a little bit to make

the whole thing doable on the router, or if tool changes are an

option, we could have it do the design with a bigger bit and then

switch to a small one to finish off and make the corners a bit closer

to the pointiness intended.

> --

> You received this message because you are subscribed to the Google Groups

> "ATXHS Discuss" group.

> To unsubscribe from this group and stop receiving emails from it, send an

> email to atxhs-discus...@googlegroups.com.

> To post to this group, send email to atxhs-...@googlegroups.com.

> Visit this group at http://groups.google.com/group/atxhs-discuss.

> For more options, visit https://groups.google.com/d/optout.

possible. What size could we get with the dust shoe on? Something like

5.5 feet?

I've attached an Inkscape-friendly SVG of the logo that will be made

into the sign. You can see on the tree-trunk the parts that have the

sharp corners I mentioned. We could round those a little bit to make

the whole thing doable on the router, or if tool changes are an

option, we could have it do the design with a bigger bit and then

switch to a small one to finish off and make the corners a bit closer

to the pointiness intended.

> You received this message because you are subscribed to the Google Groups

> "ATXHS Discuss" group.

> To unsubscribe from this group and stop receiving emails from it, send an

> email to atxhs-discus...@googlegroups.com.

> To post to this group, send email to atxhs-...@googlegroups.com.

> Visit this group at http://groups.google.com/group/atxhs-discuss.

> For more options, visit https://groups.google.com/d/optout.

Tim Fredlund

Feb 23, 2015, 12:09:42 PM2/23/15

to atxhs-discuss

I suspect you mean 4.5 feet with the dust shoe? : D

Tim Fredlund | @ethosrot | #tc

Paul Bonser

Feb 23, 2015, 12:48:58 PM2/23/15

to atxhs-...@googlegroups.com

Haha, yes. That is what I meant.

rc3105

Feb 23, 2015, 6:06:52 PM2/23/15

to atxhs-discuss

won't it need to be assembled from at least 4 pieces of plywood?

unless you're ordering sheets more than 4 feet wide???

-

R

unless you're ordering sheets more than 4 feet wide???

-

R

Tim Fredlund

Feb 23, 2015, 6:13:54 PM2/23/15

to atxhs-discuss

You can get 5x5 pieces of plywood -- part of the principle reason the active area for the table CNC is wider than 4x8.

Tim Fredlund | @ethosrot | #tc

R

Danny Miller

Feb 23, 2015, 7:16:23 PM2/23/15

to atxhs-...@googlegroups.com

Alright are the square what stays, or goes?

Danny

Danny

Paul Bonser

Feb 23, 2015, 9:58:08 PM2/23/15

to atxhs-...@googlegroups.com

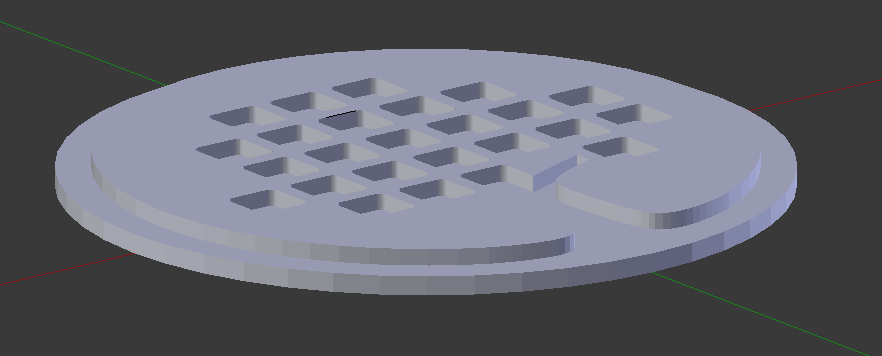

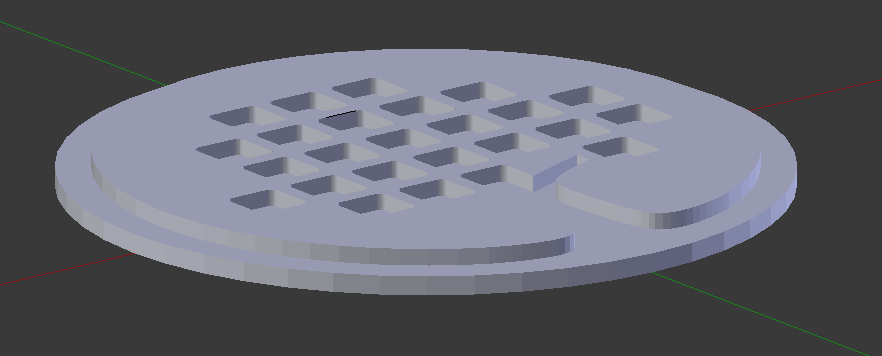

Here's a filled version for clarity.

The black part is carved half way into the bottom layer. Then it is

cut out of the top layer and inset into the holes in the bottom layer.

So the final product will be the multiple shapes of the black portion

sticking out of a solid layer underneath.

I'll show you a 3d model of the final product as soon as I finish

extruding it in Blender in a few minutes.

The black part is carved half way into the bottom layer. Then it is

cut out of the top layer and inset into the holes in the bottom layer.

So the final product will be the multiple shapes of the black portion

sticking out of a solid layer underneath.

I'll show you a 3d model of the final product as soon as I finish

extruding it in Blender in a few minutes.

Paul Bonser

Feb 24, 2015, 12:06:35 AM2/24/15

to atxhs-...@googlegroups.com

And just to be clear (and because I just spent a bunch of time re-learning how to use blender),

the top layer:

and the bottom layer:

I think those show the idea really well how the top pieces will nest into the bottom pieces.

Danny Miller

Feb 24, 2015, 12:19:58 AM2/24/15

to atxhs-...@googlegroups.com

What's the thickness of plywood here?

Danny

Danny

Danny Miller

Feb 24, 2015, 2:41:42 AM2/24/15

to atxhs-...@googlegroups.com

OK, I have toolpaths.

I used 3/4" plywood in the model and got 1hr 37min of machine time to do

the cutout sheet and the pocketed base.

Danny

I used 3/4" plywood in the model and got 1hr 37min of machine time to do

the cutout sheet and the pocketed base.

Danny

Danny Miller

Feb 24, 2015, 2:54:09 AM2/24/15

to atxhs-...@googlegroups.com

You gonna be able to transport a 5ft diameter sign??

Danny

Danny

Paul Bonser

Feb 24, 2015, 9:58:33 AM2/24/15

to atxhs-...@googlegroups.com

Oh yeah, I didn't make the thickness of the 3D models to scale, I was

just demonstrating the general concept.

The plywood I was planning on using will be 1/2"

And yes, we'll be able to put the sign in the back of a truck at an angle.

just demonstrating the general concept.

The plywood I was planning on using will be 1/2"

And yes, we'll be able to put the sign in the back of a truck at an angle.

Paul Bonser

Feb 24, 2015, 12:27:00 PM2/24/15

to atxhs-...@googlegroups.com

Also, can we do a scaled-down test run on some 1/4" ply?

Paul Bonser

Mar 3, 2015, 1:31:55 PM3/3/15

to atxhs-...@googlegroups.com

Danny, will you be by the space today? I'm going to pick up the plywood in a bit and I'd love to get this cut out today.

Joseph Ngo

Mar 3, 2015, 1:34:17 PM3/3/15

to atxhs-...@googlegroups.com

Could someone please shoot video on the cut. Thanks. Also what time if it is going to happen today?

Danny Miller

Mar 3, 2015, 3:20:31 PM3/3/15

to atxhs-...@googlegroups.com

Probably 8PM or so. So this is like

the first time doing sheet so we're gonna be fumbling with

software and holddowns and feedrates.

I did load up your PDF and make some toolpaths that should work.

Danny

I did load up your PDF and make some toolpaths that should work.

Danny

Paul Bonser

Mar 3, 2015, 3:40:22 PM3/3/15

to atxhs-...@googlegroups.com

Sounds good! I've got the wood here at the space now and I'll be

around the space for the rest of the day.

I did get the 1/2" plywood rather than 3/4", if that makes a

difference or means we'll need to regenerate the toolpaths. Also I'd

like to try a scaled down version on some 1/4" ply first, so that

should give us an idea of how it will go with a larger sheet. Or I

guess a smaller piece of 1/2" plywood would make for a good test as

well.

around the space for the rest of the day.

I did get the 1/2" plywood rather than 3/4", if that makes a

difference or means we'll need to regenerate the toolpaths. Also I'd

like to try a scaled down version on some 1/4" ply first, so that

should give us an idea of how it will go with a larger sheet. Or I

guess a smaller piece of 1/2" plywood would make for a good test as

well.

Clio Dunn

Mar 3, 2015, 7:09:03 PM3/3/15

to atxhs-discuss

Yes, I can be there by 8pm to shoot video. Just don't start early. I'll be there at 8pm.

Reply all

Reply to author

Forward

0 new messages