Looking for comments about Deltas...

Ian Smith

Or are they fun to watch, but not worth the trouble and I should just stock with what I know. This would be an additional printer not a replacement.

Hoping for an interesting discussion.

Nick Wimpney

--

You received this message because you are subscribed to the Google Groups "3D604" group.

To unsubscribe from this group and stop receiving emails from it, send an email to 3d604+un...@googlegroups.com.

To post to this group, send email to 3d...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/3d604/a47176bf-0e2d-4e63-a11f-3441db905806%40googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

Ian Smith

Thank you for the quick response. OK I'll do some more reading and try one from scratch. If it doesn't work out, I may buy a kit. Any other suggestions would be appreciated.

John Biehler

Thank you for the quick response. OK I'll do some more reading and try one from scratch. If it doesn't work out, I may buy a kit. Any other suggestions would be appreciated.

--

You received this message because you are subscribed to the Google Groups "3D604" group.

To unsubscribe from this group and stop receiving emails from it, send an email to 3d604+un...@googlegroups.com.

To post to this group, send email to 3d...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/3d604/CAMQ1g7oGd-PerH89L_o%3Dobx8TntGuOsiN7x%3D7h4Def%2BRuspDow%40mail.gmail.com.

Kimball Andersen

Nick Wimpney

I own a Solidoodle 2, and built a Rostock Max at work. I will say that while the RMax is a nice kit, the beams and joints that it comes with are a bit sloppy, especially if you want to move towards a multi nozzle setup. We ended up replacing the stock rods with the carbon fiber rod kit from trick laser, which improved it substantially. If I were you I would build it from scratch, but go with magnetic ball ends and precision cut rods. Calibrating the system is critical, and the less slop you have in everything, the better. Once they are calibrated well though, they print beautifully. it took me months of calibrating my cartesian to print perfectly round cylinders, while the delta does it effortlessly.K

--

You received this message because you are subscribed to the Google Groups "3D604" group.

To unsubscribe from this group and stop receiving emails from it, send an email to 3d604+un...@googlegroups.com.

To post to this group, send email to 3d...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/3d604/2177b485-96bd-4e37-a11c-d3940d0288e0%40googlegroups.com.

Ian Smith

Nick Wimpney

I just used the dimensions of the rostock for reference. I think the info is on reprap.org they actually aren't critical, but maintaining similar rod angles is probably a safe bet. I scaled mine up a bit so I can use a 12" tile for a print surface., just do it proportionally and it will be fine. I added 20% to the centre to tower, so also added 20% to the diagonal rod lengths. They are all adjustable in the firmware. As far as height goes, it doesn't matter. For a rough estimate, just take the build height you want, add your diagonal rod length, hot end protrusion and the height of the motor mounts. You will be able to print a bit taller near the middle of the table. I wouldn't go too crazy though, unless you plan to print a lot of vases. I used 762mm smooth rods on mine, and that gives me about 30cm of max height. The more height you have, the more you have to worry about wobbles.

Gerald Orban

Ian Smith

Sounds great! I'll think about it and then talk myself out of one that could print a lifesize version of my mini-me.ca scan. 8)

I dont think i will try anything crazy, just want a delta to play with.

I just used the dimensions of the rostock for reference. I think the info is on reprap.org they actually aren't critical, but maintaining similar rod angles is probably a safe bet. I scaled mine up a bit so I can use a 12" tile for a print surface., just do it proportionally and it will be fine. I added 20% to the centre to tower, so also added 20% to the diagonal rod lengths. They are all adjustable in the firmware. As far as height goes, it doesn't matter. For a rough estimate, just take the build height you want, add your diagonal rod length, hot end protrusion and the height of the motor mounts. You will be able to print a bit taller near the middle of the table. I wouldn't go too crazy though, unless you plan to print a lot of vases. I used 762mm smooth rods on mine, and that gives me about 30cm of max height. The more height you have, the more you have to worry about wobbles.

--

You received this message because you are subscribed to a topic in the Google Groups "3D604" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/3d604/EvSLhDbEdV4/unsubscribe.

To unsubscribe from this group and all its topics, send an email to 3d604+un...@googlegroups.com.

To post to this group, send email to 3d...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/3d604/CA%2BmEz%2Bpj_bodsKQn87BYzNnKtU0FZAqsRqbtpfXVZJVxXAxPDg%40mail.gmail.com.

Kimball Andersen

Graeme Bennett

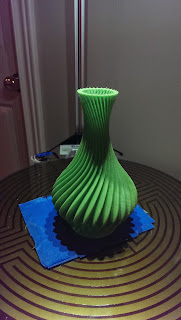

The biggest and best of the bunch is the Canadian-made Boots Industries BI v2.5, as detailed at bootsindustries.com. I'm selling it (fully assembled) below my cost. Contact me or text me at 604-442-3512 if you are interested. Here is a sample of its impressive print quality.

I also have a Canadian made Mixshop Kossel printer (as seen at mixshop.ca), also fully assembled, will sell below my cost. Contact me for details.

Ian Smith

KP Chiang

Nick,

Kimball Andersen

Nick Wimpney

--

You received this message because you are subscribed to the Google Groups "3D604" group.

To unsubscribe from this group and stop receiving emails from it, send an email to 3d604+un...@googlegroups.com.

To post to this group, send email to 3d...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/3d604/32609bfd-7057-4d05-91bd-50b3e4b85048%40googlegroups.com.

KP Chiang

Derek P

Jeremiah Timmins

I have nothing to compare it to but deriving a conclusion about prefab vs reprap evos isn't hard. I believe the maker bots and other prefab units have limited issues. I've diagnosed a number of minor issues (pla composites affecting consistent output, getting clogged or not flowing at a consistent rate, hot end temperatures falling under target, print adhesion for place and abs, overheating wires, etc).

It takes an obscene amount of time to design something that works well, especially from the first print. Combine that with a delta or any reprap and you're working long hours. At least initially. I have noticed that factor leveling off if its put to a graph, time vs productivity.

This isn't a hobby for wimps. It takes brains, time, creative juice, experience and some bandages to gain the wisdom to create anything worth bragging about. It can also help to have someone validate all the stupid things that you make...that's one of the many reasons I love my family.

Best of luck with your adventure!

Ian Smith

Just to update everyone on my delta work. I picked up a boot industries V2.5, and a small delta on craigslist. The Boots was working reasonably well, but results were inconsistent. Eventually, I realized one end stop has not working properly. I'm going to debug, probably a broken wiring connection. The small delta parts were made with very brittle PLA. I'm slowly making new parts for the small delta with a better PLA and different design. It's not a priority, but it is slowly taking shape.

The deltas are still much more interesting to watch than an xyz. Currently I'm getting better results with the Rigidbot.

Ian