Laser etching on a curved surface

58 views

Skip to first unread message

JF Mather

Sep 14, 2021, 8:40:32 AM9/14/21

to rLab / Reading's Hackspace

Hello,

May I ask if the laser cutter can do etching on a curved surface?

Regards,

Jonathan.

Jeremy Poulter

Sep 14, 2021, 12:27:43 PM9/14/21

to rLab List

Hi,

Depends how curved, or more accurately how far away the laser head gets from the work surface. If only a few extra mm you are probably good.

Cheers,

Jeremy

--

You received this message because you are subscribed to the Google Groups "rLab / Reading's Hackspace" group.

To unsubscribe from this group and stop receiving emails from it, send an email to reading-hacksp...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/reading-hackspace/bca0f11b-b694-4915-82b4-2aaa22eed2f0n%40googlegroups.com.

JF Mather

Sep 15, 2021, 5:06:13 AM9/15/21

to rLab / Reading's Hackspace

Ok, I think I understand. I actually have a cylinder (5mm diameter), and I'd like to rotate it so that I can write a 360 degree etched pattern on it. (Sorry I didn't write that initially). My best idea at the moment is to construct my own rig that will rotate it slowly, but that's going to be quite a project.

Thanks for the reply,

Jonathan.

Stephen Rodway

Sep 15, 2021, 5:10:09 AM9/15/21

to reading-...@googlegroups.com

Yes that's quite a large project to build a rotator, but fortunately

probably not needed!

At 5mm diameter, the focal depth of the laser of around 2mm will let you

write quite a long way around the cylinder in one go. So what you can do

is set up a jig to position your work in the laser with good

repeatability, then just index it around a few times and do the etch in

maybe 3-6 separate operations.

The repeatability is important if you want the pattern to line up

nicely, but it's not that hard to arrange. Indexing also needs to be

reasonably accurate but you can get that either by eye using the

alignment laser, or you could use something like collet blocks to give

accurate rotation.

Steve

> <https://groups.google.com/d/msgid/reading-hackspace/bca0f11b-b694-4915-82b4-2aaa22eed2f0n%40googlegroups.com?utm_medium=email&utm_source=footer>.

> <https://groups.google.com/d/msgid/reading-hackspace/a3604bdd-61d6-4a2d-b582-ccef34bf4946n%40googlegroups.com?utm_medium=email&utm_source=footer>.

probably not needed!

At 5mm diameter, the focal depth of the laser of around 2mm will let you

write quite a long way around the cylinder in one go. So what you can do

is set up a jig to position your work in the laser with good

repeatability, then just index it around a few times and do the etch in

maybe 3-6 separate operations.

The repeatability is important if you want the pattern to line up

nicely, but it's not that hard to arrange. Indexing also needs to be

reasonably accurate but you can get that either by eye using the

alignment laser, or you could use something like collet blocks to give

accurate rotation.

Steve

>

> --

> You received this message because you are subscribed to the Google

> Groups "rLab / Reading's Hackspace" group.

> To unsubscribe from this group and stop receiving emails from it, send

> an email to reading-hacksp...@googlegroups.com

> <mailto:reading-hacksp...@googlegroups.com>.

> --

> You received this message because you are subscribed to the Google

> Groups "rLab / Reading's Hackspace" group.

> To unsubscribe from this group and stop receiving emails from it, send

> an email to reading-hacksp...@googlegroups.com

> To view this discussion on the web, visit

> https://groups.google.com/d/msgid/reading-hackspace/a3604bdd-61d6-4a2d-b582-ccef34bf4946n%40googlegroups.com

> <https://groups.google.com/d/msgid/reading-hackspace/a3604bdd-61d6-4a2d-b582-ccef34bf4946n%40googlegroups.com?utm_medium=email&utm_source=footer>.

Tony Short

Sep 15, 2021, 6:21:35 AM9/15/21

to rLab / Reading's Hackspace

Lining up a repeating pattern on something that small is going to be a real pain. If you let us know what you are trying to achieve there may be a better solution.

T

Tom Allen

Sep 15, 2021, 6:33:53 AM9/15/21

to reading-...@googlegroups.com, scott murdoch

I gave a laser cutter rotator to Scott Murdoch for rlab, no idea if he got round to testing it. It had a nice rubber cone clamp and another moving support too so should be able to hold various works

To view this discussion on the web, visit https://groups.google.com/d/msgid/reading-hackspace/e0384599-ef22-4183-9f0a-9b793acd853fn%40googlegroups.com.

JF Mather

Sep 15, 2021, 6:39:31 AM9/15/21

to rLab / Reading's Hackspace

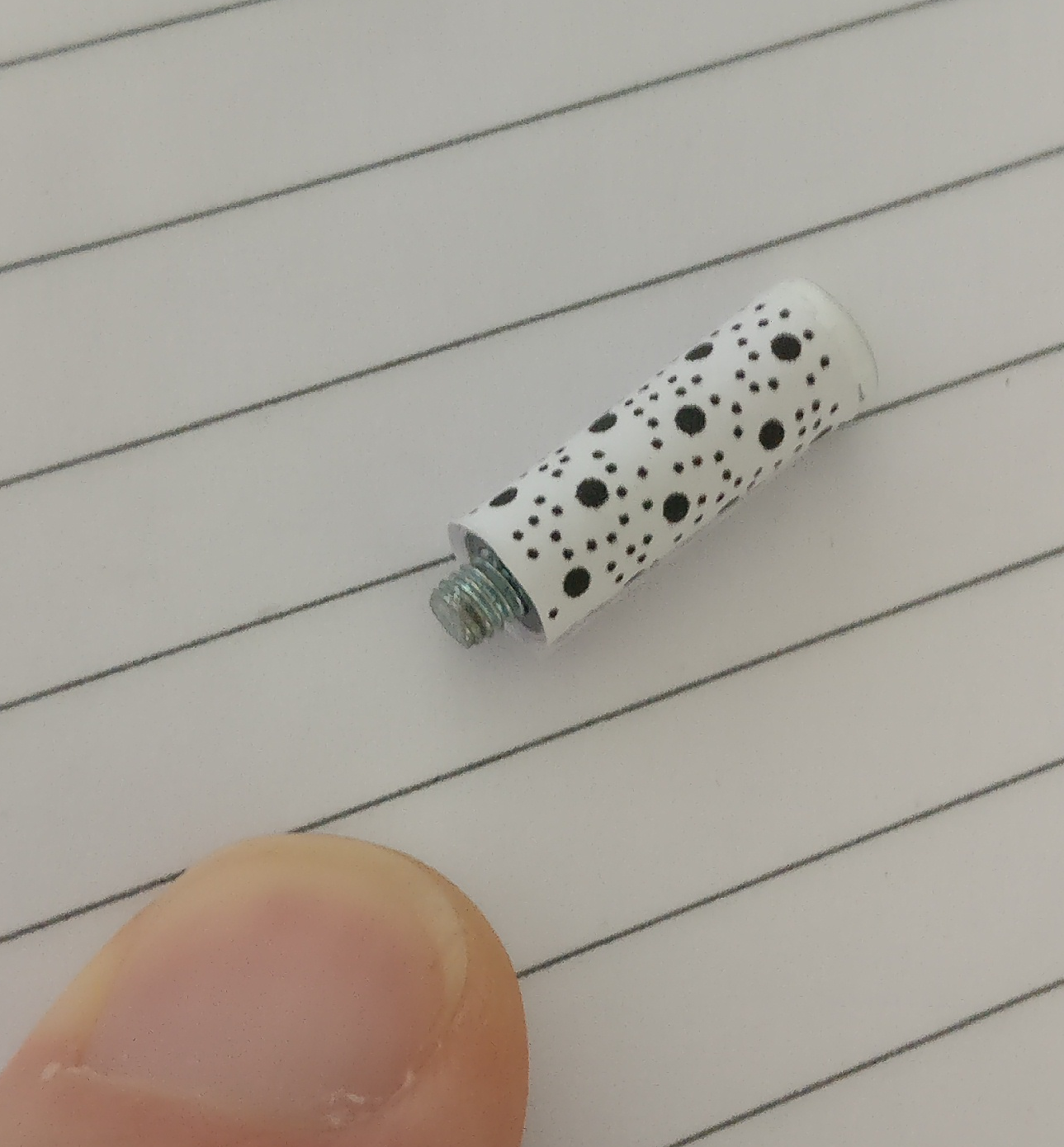

Thanks Stephen, that collet idea is nice and I hadn't considered that at all. In case there are even better ideas... here is a photo of a prototype of what I am trying to make. Its a cylinder with printed paper wrapped around it. But I'd like the post to be titanium and then anodise it black where the dots are, using the laser... like this:

Steve Rodway

Sep 15, 2021, 6:58:33 AM9/15/21

to reading-...@googlegroups.com

OK that pattern probably makes this easier for you because the somewhat

random dot pattern isn't going to require accurate registration to look OK.

I'm not aware of anyone using our laser to mark titanium yet. As I

understand it titanium can be lightly marked with a CO2 laser but people

have got very mixed results. I'm pretty sure the one in the video you

showed was an Nd:YAG laser galvanometer-type engraver which is better

suited to the job. We've thought about getting one of those in the past

but good ones are quite expensive.

Using the laser here you'll probably have to watch out for resolution

issues (the spot size is about 0.25mm right now, and will be much larger

when it's on a curve) and overall heating of the part, get it too hot

and the whole thing will colour.

Steve

On 15/09/2021 11:39, JF Mather wrote:

> Thanks Stephen, that collet idea is nice and I hadn't considered that at

> all. In case there are even better ideas... here is a photo of a

> prototype of what I am trying to make. Its a cylinder with printed

> paper wrapped around it. But I'd like the post to be titanium and then

> anodise it black where the dots are, using the laser... like this:

> https://www.youtube.com/watch?v=T9u3D4T_X0c&ab_channel=LaserMarkingTechnologies%2CLLC.

>

>

> <https://groups.google.com/d/msgid/reading-hackspace/bca0f11b-b694-4915-82b4-2aaa22eed2f0n%40googlegroups.com?utm_medium=email&utm_source=footer

> <https://groups.google.com/d/msgid/reading-hackspace/a3604bdd-61d6-4a2d-b582-ccef34bf4946n%40googlegroups.com?utm_medium=email&utm_source=footer>>.

> <https://groups.google.com/d/msgid/reading-hackspace/684629b5-9875-4cdf-81c7-63f4dedc34b2n%40googlegroups.com?utm_medium=email&utm_source=footer>.

random dot pattern isn't going to require accurate registration to look OK.

I'm not aware of anyone using our laser to mark titanium yet. As I

understand it titanium can be lightly marked with a CO2 laser but people

have got very mixed results. I'm pretty sure the one in the video you

showed was an Nd:YAG laser galvanometer-type engraver which is better

suited to the job. We've thought about getting one of those in the past

but good ones are quite expensive.

Using the laser here you'll probably have to watch out for resolution

issues (the spot size is about 0.25mm right now, and will be much larger

when it's on a curve) and overall heating of the part, get it too hot

and the whole thing will colour.

Steve

On 15/09/2021 11:39, JF Mather wrote:

> Thanks Stephen, that collet idea is nice and I hadn't considered that at

> all. In case there are even better ideas... here is a photo of a

> prototype of what I am trying to make. Its a cylinder with printed

> paper wrapped around it. But I'd like the post to be titanium and then

> anodise it black where the dots are, using the laser... like this:

> https://www.youtube.com/watch?v=T9u3D4T_X0c&ab_channel=LaserMarkingTechnologies%2CLLC.

>

>

> <https://groups.google.com/d/msgid/reading-hackspace/bca0f11b-b694-4915-82b4-2aaa22eed2f0n%40googlegroups.com?utm_medium=email&utm_source=footer>>.

>

> >

> > --

> > You received this message because you are subscribed to the

> Google

> > Groups "rLab / Reading's Hackspace" group.

> > To unsubscribe from this group and stop receiving emails from

> it, send

> > an email to reading-hacksp...@googlegroups.com

> > <mailto:reading-hacksp...@googlegroups.com>.

> > To view this discussion on the web, visit

> >

> https://groups.google.com/d/msgid/reading-hackspace/a3604bdd-61d6-4a2d-b582-ccef34bf4946n%40googlegroups.com

> <https://groups.google.com/d/msgid/reading-hackspace/a3604bdd-61d6-4a2d-b582-ccef34bf4946n%40googlegroups.com>

>

> >

> <https://groups.google.com/d/msgid/reading-hackspace/a3604bdd-61d6-4a2d-b582-ccef34bf4946n%40googlegroups.com?utm_medium=email&utm_source=footer

>

> >

> > --

> > You received this message because you are subscribed to the

> > Groups "rLab / Reading's Hackspace" group.

> > To unsubscribe from this group and stop receiving emails from

> it, send

> > an email to reading-hacksp...@googlegroups.com

> > <mailto:reading-hacksp...@googlegroups.com>.

> > To view this discussion on the web, visit

> >

> https://groups.google.com/d/msgid/reading-hackspace/a3604bdd-61d6-4a2d-b582-ccef34bf4946n%40googlegroups.com

> <https://groups.google.com/d/msgid/reading-hackspace/a3604bdd-61d6-4a2d-b582-ccef34bf4946n%40googlegroups.com>

>

> >

> <https://groups.google.com/d/msgid/reading-hackspace/a3604bdd-61d6-4a2d-b582-ccef34bf4946n%40googlegroups.com?utm_medium=email&utm_source=footer>>.

>

>

> --

> You received this message because you are subscribed to the Google

> Groups "rLab / Reading's Hackspace" group.

> To unsubscribe from this group and stop receiving emails from it, send

> an email to reading-hacksp...@googlegroups.com

> <mailto:reading-hacksp...@googlegroups.com>.

> To view this discussion on the web, visit

> https://groups.google.com/d/msgid/reading-hackspace/684629b5-9875-4cdf-81c7-63f4dedc34b2n%40googlegroups.com

>

> --

> You received this message because you are subscribed to the Google

> Groups "rLab / Reading's Hackspace" group.

> To unsubscribe from this group and stop receiving emails from it, send

> an email to reading-hacksp...@googlegroups.com

> <mailto:reading-hacksp...@googlegroups.com>.

> To view this discussion on the web, visit

> <https://groups.google.com/d/msgid/reading-hackspace/684629b5-9875-4cdf-81c7-63f4dedc34b2n%40googlegroups.com?utm_medium=email&utm_source=footer>.

Andrew

Sep 15, 2021, 8:20:34 AM9/15/21

to reading-...@googlegroups.com

You might also be able to laser cut an etching stencil for chemical etching. I'm not well versed in etching, especially titanium, but it might be worth investigating.

To view this discussion on the web, visit https://groups.google.com/d/msgid/reading-hackspace/504905d1-5cee-72ab-163f-43ef198e478b%40legionelectronics.co.uk.

Carlo Zinzani

Sep 15, 2021, 8:05:31 PM9/15/21

to reading-...@googlegroups.com

Yeah chemical (nitric acid) etching would be probably faster. In artistic etching you would protect your metal with a sort of string wax, the same a violinist would use on the bow. You need some heat to melt some of the wax then with a vinyl roll it can be spread on the metal. Any wax would work I guess... Bitumen's paint or sealant is also used in artistic printing.

A sticker would probably work the same as a layer of wax.

If you wanted to experiment further...

A sticker would probably work the same as a layer of wax.

If you wanted to experiment further...

You can also try to print the negative of your pattern on paper with normal toner, transfer the pattern on the metal by laying the printed side against the metal then with some cotton drenched in acetone if you rub it on the back side of the paper you would be able to transfer the toner from the paper to the metal.

If it transfer reasonably then you can try to submerge our metal in acid... depending on your solution concentration you'll wait 5-15 min depending on the depth you want to achieve.

Toner can be removed again with a solvent or acetone.

Your metal need to be clean before attaching any wax or toner to it.

A sticker would probably give you better control on lines of your pattern.

If it transfer reasonably then you can try to submerge our metal in acid... depending on your solution concentration you'll wait 5-15 min depending on the depth you want to achieve.

Toner can be removed again with a solvent or acetone.

Your metal need to be clean before attaching any wax or toner to it.

A sticker would probably give you better control on lines of your pattern.

To view this discussion on the web, visit https://groups.google.com/d/msgid/reading-hackspace/CANfu%2Bi111CxxMW4xodUYL5mV570zAQFcQkpTeDQ%2BYa_DSsbF0w%40mail.gmail.com.

JF Mather

Sep 17, 2021, 4:28:11 AM9/17/21

to rLab / Reading's Hackspace

This video shows a co2 laser marking titanium pretty well, so I'll give it a try with a collet to start with and see how it goes, that laser cutter rotator sounds pretty useful though, I hope it might turn up.

Thanks for your tips.

Reply all

Reply to author

Forward

0 new messages