Arc Motion

Ravi Ganesh

mark maker

This won't help in the general case, because the arc is either in the XZ plane (G18) or in the YZ plane (G19). Only if you have completely orthogonal moves in X or Y would this be a smooth path. But such moves almost never happen in OpenPnP, most are at arbitrary diagonals.

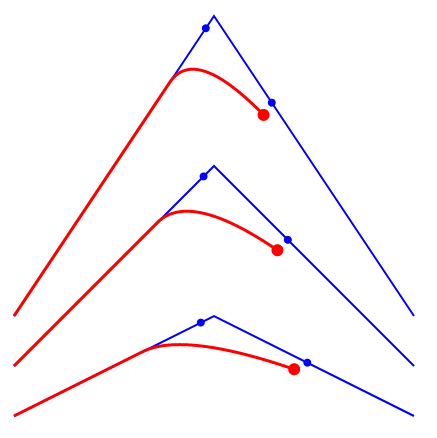

Even if you were to select the closer of the two planes, you get

a corner in the path, at the top. The corner angle would be

blunter than 90°, so maybe it would allow going through that

corner a bit faster (junction

deviation), but your overall path is longer, so I don't

think this will gain much.

The real solution is supporting something like G64:

https://linuxcnc.org/docs/2.6/html/gcode/gcode.html#sec:G64

And then calculate the blending dynamically, i.e. large blending

for long moves, only little blending for short moves.

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/2091949c-a319-4aac-99dc-4757fd69c09bn%40googlegroups.com.

surab...@gmail.com

Mark,

IMO this gcode:

G18;

..

G03 X3 Z15 Y3 R5;

Is an arc in a plane at 45 degree to the XZ plane and orthogonal to XY.

So using G18 and G19 arc in any vertical plane is possible. (I think the video proves that)

However I have no Idea whether blending is better than arcs.

But definitely I want to ask why arc was not considered so long, when it is already available.

R

--

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/PxliLkN6JBU/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/f0a6e78d-b5f7-aee5-a351-bd0402fd2e6b%40makr.zone.

Arthur Wolf

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/f0a6e78d-b5f7-aee5-a351-bd0402fd2e6b%40makr.zone.

--

勇気とユーモア

bert shivaan

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAMHZkm4%2BTxYz%2Bw5RM3zjSd1%3D0nFimMp959_DL2uV1tkm1Dyraw%40mail.gmail.com.

mark maker

> IMO this gcode: G18; G03 X3 Z15 Y3 R5; Is an arc in a plane at 45 degree to the XZ plane and orthogonal to XY.

I don't think that is an arc in the 45° plane. It is a helix

(like a screw thread) with 3mm climb in the Y axis.

As the helix climb is constant per angle, this means there are even two corners, one at the base of the arc, and one at the top. Two corners means this is certainly slower than rectangular motion.

https://www.cnccode.com/4132/siemens-cnc-milling-g02-g03-turn-helix-interpolation

Grbl is no exception, you can see here, there's only 2D math :

https://github.com/grbl/grbl/blob/9180094b72821ce68e33fdd779278a533a7bf40c/grbl/gcode.c#L676

and btw. what would be the point of G18 and G19 if the command could specify the plane 😉?

> You *could* generate the arc as a series of small gcodes (do the full 3D math in openpnp)

OpenPnP can do that!

See here:

https://github.com/openpnp/openpnp/wiki/Motion-Planner#motion-blending

Unfortunately, after having programmed all this, it turned out the USB serial speed of the tested controllers is not fast enough. It takes more time to send these fine-grained paths, than what it saves in motion time

😭.

In theory it all worked nicely, I'll try to find the simulated

illustration.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAMHZkm4%2BTxYz%2Bw5RM3zjSd1%3D0nFimMp959_DL2uV1tkm1Dyraw%40mail.gmail.com.

Arthur Wolf

> IMO this gcode: G18; G03 X3 Z15 Y3 R5; Is an arc in a plane at 45 degree to the XZ plane and orthogonal to XY.

I don't think that is an arc in the 45° plane. It is a helix (like a screw thread) with 3mm climb in the Y axis.

As the helix climb is constant per angle, this means there are even two corners, one at the base of the arc, and one at the top. Two corners means this is certainly slower than rectangular motion.

https://www.cnccode.com/4132/siemens-cnc-milling-g02-g03-turn-helix-interpolation

Grbl is no exception, you can see here, there's only 2D math :

https://github.com/grbl/grbl/blob/9180094b72821ce68e33fdd779278a533a7bf40c/grbl/gcode.c#L676

and btw. what would be the point of G18 and G19 if the command could specify the plane 😉?

> You *could* generate the arc as a series of small gcodes (do the full 3D math in openpnp)

OpenPnP can do that!

See here:

https://github.com/openpnp/openpnp/wiki/Motion-Planner#motion-blending

Unfortunately, after having programmed all this, it turned out the USB serial speed of the tested controllers is not fast enough. It takes more time to send these fine-grained paths, than what it saves in motion time

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/26919260-9ccf-e9f7-fcef-75385d856b89%40makr.zone.

--

勇気とユーモア

surab...@gmail.com

Well said Mark. What really matters is that angle. Worst case this angle is 22.5 degree.

IMO this helix could still be considered and the practical results might be appealing compared to the development effort.

I will give this one also a try….

From: ope...@googlegroups.com <ope...@googlegroups.com> On Behalf Of mark maker

Sent: Thursday, December 2, 2021 11:05 PM

To: ope...@googlegroups.com

Subject: Re: [OpenPnP] Arc Motion

> IMO this gcode: G18; G03 X3 Z15 Y3 R5; Is an arc in a plane at 45 degree to the XZ plane and orthogonal to XY.

--

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/PxliLkN6JBU/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/26919260-9ccf-e9f7-fcef-75385d856b89%40makr.zone.

surab...@gmail.com

Hi Arthur,

Here is a gcode fragment to make a diagonal pick and place from 0,0 to 100,100

using interpolated arcs.

Z plane is 15mm.

Safe height is 10mm (i.e the minimum height the head retracts up before making any horizontal component move.

G01 X0 Y0 Z0 F10000

Z10.

X0.0141 Y0.0141 Z10.4467

X0.0564 Y0.0564 Z10.8897

X0.1265 Y0.1265 Z11.3257

X0.2239 Y0.2239 Z11.7511

X0.3478 Y0.3478 Z12.1624

X0.4971 Y0.4971 Z12.5565

X0.6707 Y0.6707 Z12.9302

X0.8673 Y0.8673 Z13.2804

X1.0851 Y1.0851 Z13.6043

X1.3226 Y1.3226 Z13.8995

X1.5778 Y1.5778 Z14.1635

X1.8486 Y1.8486 Z14.3941

X2.1329 Y2.1329 Z14.5897

X2.4284 Y2.4284 Z14.7485

X2.7328 Y2.7328 Z14.8694

X3.0436 Y3.0436 Z14.9514

X3.3583 Y3.3583 Z14.9937

X3.5355 Y3.5355 Z15.

X6.9773 Y6.9773

X96.4645 Y96.4645

X96.6417 Y96.6417 Z14.9937

X96.9564 Y96.9564 Z14.9514

X97.2672 Y97.2672 Z14.8694

X97.5716 Y97.5716 Z14.7485

X97.8671 Y97.8671 Z14.5897

X98.1514 Y98.1514 Z14.3941

X98.4222 Y98.4222 Z14.1635

X98.6774 Y98.6774 Z13.8995

X98.9149 Y98.9149 Z13.6043

X99.1327 Y99.1327 Z13.2804

X99.3293 Y99.3293 Z12.9302

X99.5029 Y99.5029 Z12.5565

X99.6522 Y99.6522 Z12.1624

X99.7761 Y99.7761 Z11.7511

X99.8735 Y99.8735 Z11.3257

X99.9436 Y99.9436 Z10.8897

X99.9859 Y99.9859 Z10.4467

X100. Y100. Z10.

Z0.

Arthur Wolf

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/000301d7e7ec%24f641e250%24e2c5a6f0%24%40gmail.com.

--

勇気とユーモア

mark maker

> Could I get some sample gcode for this?

First let me tell you that Grbl hardly has a planner queue that

is long enough, even the 32bit controller like Smoothie and Duet

are quite challenged by that (RAM-wise, and processing wise). Grbl

will not be able to look ahead until the end of the segment

sequence and therefore it will conservatively decelerate way

too early. You will get very strange, stuttery moves!

Furthermore: this only works if you have an acceleration control

command like M204.

But just to get the G-code as an academic exercise, enable the

feature in OpenPnP as follows. Please take the time to really

follow this carefully step by step (however no guarantee that I

didn't miss something):

- Read about the theory:

https://github.com/openpnp/openpnp/wiki/Motion-Planner#motion-blending

- Convert the GcodeDriver to the GcodeAsyncDriver if you haven't

already. You need to proceed all the way to the Advanced

Milestone of Issues & Solution to get the

suggestion for automatic conversion.

https://github.com/openpnp/openpnp/wiki/GcodeAsyncDriver#for-existing-gcodedrivers - Set the Simulated3rdOrderControl in the

driver.

https://github.com/openpnp/openpnp/wiki/GcodeAsyncDriver#gcodedriver-new-settings

- Set the interpolation settings:

https://github.com/openpnp/openpnp/wiki/GcodeAsyncDriver#interpolation - Enable Location Confirmation on the driver.

https://github.com/openpnp/openpnp/wiki/GcodeAsyncDriver#advanced-settings

- For the academic interest: set the Log G-code option on the driver. It will log the pure G-code, separate from the usual log.

- Like in step (2), convert the NullPlanner to the ReferenceAdvancedMotionPlanner with Issues & Solutions.

- Set the Motion Planner to Allow continuous motion and

to Allow uncoordinated:

https://github.com/openpnp/openpnp/wiki/Motion-Planner#settings - You need a Safe Z Zone that is not zero, i.e. the

headroom for the curves a.k.a. Z overshoots. Set the Safe

Zone Low and Safe Zone High limits

on the Z axis. It will optimize the curve size (small

curves on short moves, large curves on long moves, limited by

the head-room of the Safe Z Zone):

https://github.com/openpnp/openpnp/wiki/Machine-Axes#kinematic-settings--axis-limits

Then try it 😎

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/000301d7e7ec%24f641e250%24e2c5a6f0%24%40gmail.com.

mark maker

I have to be more specific:

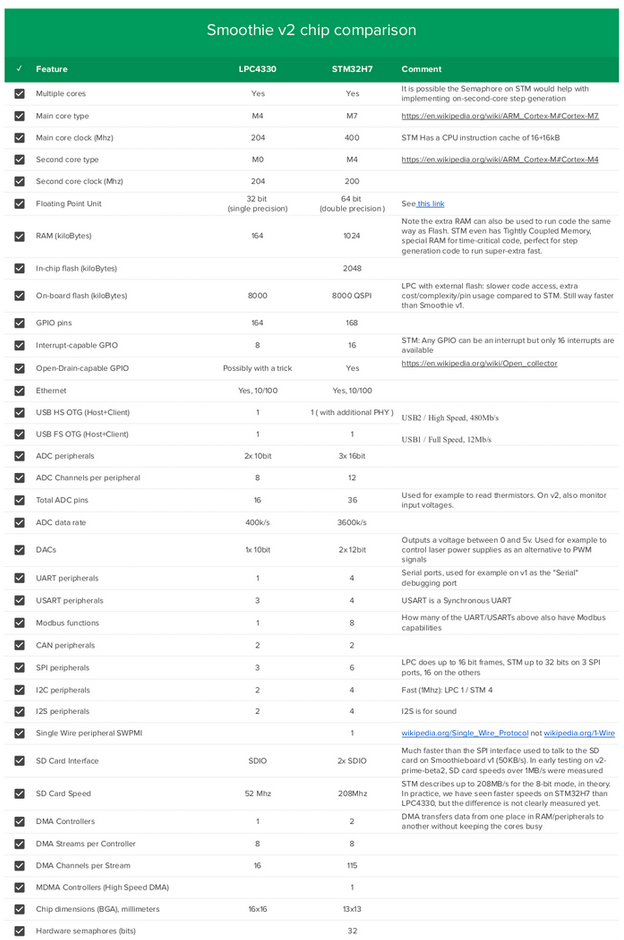

- For Smoothieware the USB speed seems good enough, but the

planner queue is too small for long moves with large

curves. For short moves it works, see the two animations:

- For Duet, the queue can be made large enough (lots of RAM) but

the USB serial speed (although it was much improved) is still

not good enough.

I have to say that I don't know if Smoothie would be performant enough (in terms of processing power) to handle a larger queue, even if the RAM was large enough.

When does Smoothie 2 finally come out? 😛

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAMHZkm7486hSwqn0zMX4WWKDNLmmpT4J5w%2BQq%2BjtH5MO7yr6Yg%40mail.gmail.com.

Arthur Wolf

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/c07eaf9c-018d-f342-7437-fb23c3a9eafb%40makr.zone.

--

勇気とユーモア

mark maker

> Could I get some sample gcode for this?

Sorry just saw that it is you who is asking, Arthur, not Ravi.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/96671a92-8b17-6666-8381-fdbd4f677686%40makr.zone.

Jan

May I summersise this thread, draw some conclusing and kindly ask for

your confirmation?

- For motion blending the controller should be able to quickly accept

and queue many smal segmens for gcode.

- For controllers with serial links the gcode should be compressed by

removing unnesseary spaces and reducing the presicion. (1/100mm and

1/10° is probably fine for all kinds of PnP requirements)

- Smoothieware V1 can provide and handle very long queues limited by the

available memory only.

- On Smoothieware V1 the queue can be adjusted via planner_queue_size

- http://smoothieware.org/configuration-options says that

planner_queue_size can be adjusted until smoothieware runs out of RAM.

- https://smoothieware.org/troubleshooting says that running out of

memory means that the mem-command reports less then 2k free space.

- on my CHM-T36VA with criegels enhanced smoothieware on STM32F407

(https://github.com/c-riegel/Smoothieware-CHMT) "mem" says "Total Free

RAM: 67348 bytes", "Free AHB0: 11192" and "Block size: 92 byte" (This

firmware has planner_queue_size set to 48).

- If I understand the source code correctly, "planner_queue_size" is

evaluated in Conveyor.cpp (Conveyor::on_module_loaded()) which is then

used to resize the queue via BlockQueue::resize() in BlockQueue.cpp

which requests memory from AHB0 pool. I guess further that each element

is of size "Block size" which is 92 byte for me.

- If I keep 2k of AHB0 free, there would be space for 99 more queue

elements summing to a total of 147. Without the 2k it would be 121 more

for a total of 169. As there is plenty of space in other pools free, it

shall be possible to provide an even larger queue.

- If I take this gcode fragment (from arc.txt) "X99.9859 Y99.9859

Z10.4467" and compress it to "X99.96Y99.96Z10.45" it contains 18

characters + new-line. 19 characters transfered at 115200 baud with 8N1

would require 1.65ms. At 1000mm/s feedrate each segment would be 1.65mm

long. At slower speeds the segments would be shorted. (This could be

even made 10% faster with 7N1 transfer)

Would that provide enough speed and space for smooth motion blending?

Jan

On 03.12.2021 14:12, Arthur Wolf wrote:

> On v1, you can make the queue longer, I've seen people do 4x on it (not

> on 3D printers, those have modules that use too much RAM), which at

> 0.1mm/block is 25.6mm, which should be plenty enough for this use case.

> It depends on how much RAM you're using for other modules/uses etc.

> Processing power is definitely not a limiting factor here, the vast

> majority of the processing on v1 goes to actual step generation.

> About v2, we've been constrained by the chip shortages, but we finally

> have a proto going to the devs this week. We upgraded to a much more

> powerful chip by the way (with lots more RAM), see the upgrade on

> Kickstarter :

>

>

>

>

>

> On Fri, Dec 3, 2021 at 2:06 PM mark maker <ma...@makr.zone> wrote:

>

> I have to be more specific:

>

> planner queue is/too small/ for long moves with large curves.

> AdvancedMotionAnimation

>

> 2. For Duet, the queue can be made large enough (lots of RAM) but

>> https://groups.google.com/d/msgid/openpnp/000301d7e7ec%24f641e250%24e2c5a6f0%24%40gmail.com

>>

>>

>> --

>>

>> 勇気とユーモア

>>

>> --

>> You received this message because you are subscribed to the Google

>> Groups "OpenPnP" group.

>> To unsubscribe from this group and stop receiving emails from it,

>> send an email to openpnp+u...@googlegroups.com

>> <https://groups.google.com/d/msgid/openpnp/CAMHZkm7486hSwqn0zMX4WWKDNLmmpT4J5w%2BQq%2BjtH5MO7yr6Yg%40mail.gmail.com?utm_medium=email&utm_source=footer>.

> --

> You received this message because you are subscribed to the Google

> Groups "OpenPnP" group.

> To unsubscribe from this group and stop receiving emails from it,

> send an email to openpnp+u...@googlegroups.com

> <https://groups.google.com/d/msgid/openpnp/c07eaf9c-018d-f342-7437-fb23c3a9eafb%40makr.zone?utm_medium=email&utm_source=footer>.

>

>

> --

>

> 勇気とユーモア

>

> --

> You received this message because you are subscribed to the Google

> Groups "OpenPnP" group.

> To unsubscribe from this group and stop receiving emails from it, send

> an email to openpnp+u...@googlegroups.com

> <https://groups.google.com/d/msgid/openpnp/CAMHZkm4qt8QO4qBTg%2B9uci7C21LDdoX1Utoqnwny9nvAEoaf%3DA%40mail.gmail.com?utm_medium=email&utm_source=footer>.

Arthur Wolf

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/3badf620-6475-a229-aa1e-273426d6525c%40googlemail.com.

--

勇気とユーモア

mark maker

Hi Jan

OpenPnP can already compress the Gcode:

- Remove comments

- Remove whitespace and unnecessary trailing digits

https://github.com/openpnp/openpnp/wiki/GcodeAsyncDriver#gcodedriver-new-settings

- You can set the resolution on the Axis, i.e. if you set it to

0.01 and adapt the format of the MOVE_TO_COMMAND (%.2f instead

of %.4f), you get what you describe.

All this was used in my tests with regular Smoothie and Duet 3 to

no avail.

There is currently no support for relative motion. That would

probably help a bit here, but create other problems.

Regular Smoothie has not enough RAM, I was able to increase the queue to 48 before it stopped working. But that's not enough. For fully smoothed operation you probably need 100-300 segments. Regular Smoothie has very fast native USB serial and flow control, but I still don't know whether it would be fast enough.

> 19 characters transfered at 115200 baud with 8N1

would require 1.65ms.

> Would that provide enough speed and space for

smooth motion blending?

The CHM-T36VA serial bridge to the STM32F407 is slow and shaky, flow control seemed not to work properly. Experiments, I think done by Nélio, did not work. Maybe there would be an option to connect native USB serial?

Duet 3 seems to have enough RAM, but its serial USB serial, while

being improved lately, is still way too slow. The last experiments

(I think by Wolfgang) did not really work out.

One problem is also to let the planner wait until it has received the whole sequence for look-ahead planning. If the planner starts planning/executing motion too quickly, it will rush into premature deceleration, not yet seeing the sequence to the end. We added some new grace period support to Duet, i.e. it would wait longer, or until an M400 is received, which typically signals the end of a sequence. I'm not sure we tested the latest incarnation of that. Any controller supporting such paths would have a grace period+release feature too.

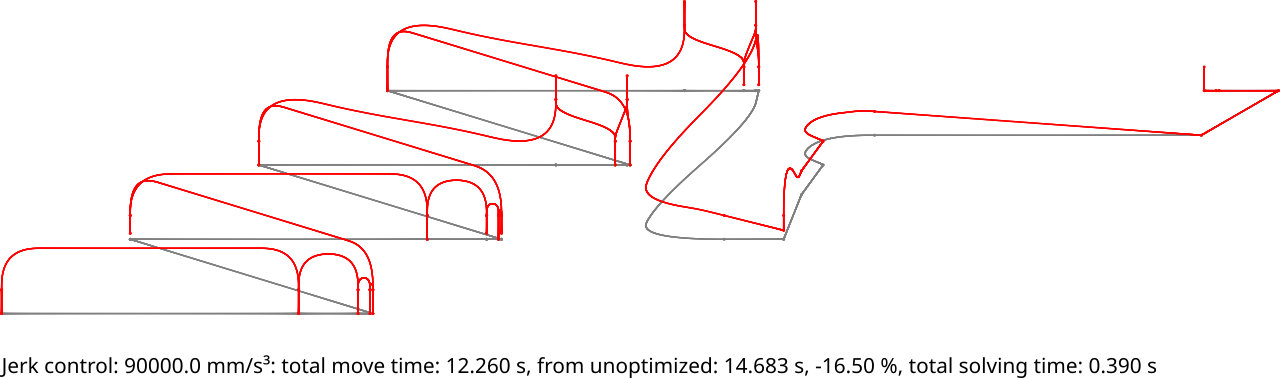

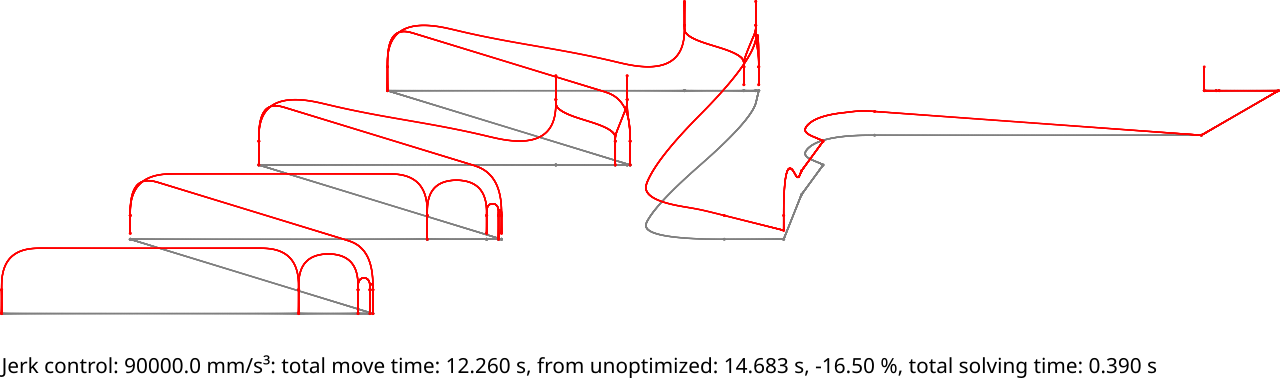

Here is a simulations with the OpenPnP Motion Planner (dual

nozzle machine, i.e. see the nozzle switch in the back row,

showing as inverted Z moves):

The gains are moderate (-16.6% time). All that planning as true 3rd order motion also requires solving time (in Java). Add to that the serial communication time and the gains were gone. 😭

I'm now quite convinced that controller side support for

smoothing is the way to go.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAMHZkm4Lz%3DdHzfzpuBB1AVXXwzS1zNKo%3DD4DtqNX_mVqu_2c1g%40mail.gmail.com.

Jan

Many thanks for your detailed response.

I'm aware that compression is available as well as the option to

control the precision. According the the log in arc.txt also unused

coordinates are not send if not needed.

The CHM-T36VA controller board has just a two-wire serial interface.

RTS/CTS for hardware flow control are not connected. Anyhow, this is -

to my understanding - only needed, if the queue is to short. If the

queue is large and the planner can respect a maximum number of slices

per segment (until it needs to wait for a move to finish) flow-control

is not needed.

The STM32F407 provides a USB full-speed device controller and phy. The

pins are accessible at the CAN connector, which is unpopulated. I guess

two series resistors and a pullup would be all thats needed to make the

physical connection. I've two concerns with this option:

a) I've read that USB interfaces might cause trouble because of ground

loops. Yes, USB isolators are easy to add.

b) Fitting USB-serial into the existing firmware would be some work and

- to my understanding - only make sense if we would gain significant

benefits.

I've started this response to gain more insights for the second point.

In software development I'd use a profiler and carefully generate

testcases to find the place where optimization would be most efficient.

I've identified some places in the past that are all addresses so far:

the criegel firmware operates the CHM-T36VA with an unbelievable speed.

As you wrote in one of your early blog posts, acceleration is all that

matters for the total speed... I'd add that optimizing move distances is

the second as hardware inertia is a bigger limit then computer speed.

You address that as well with the advanced motion planner.

If you think, that changing the way the controller handles the queue is

an efficient way to proceed, why not just do it. You already made a few

modification to smoothieware - which to my knowledge where not accepted

due to limited used for the community. If think, that a larger queue is

an other way to step forward, why not try to optimize the queue/memory

layout...

Jan

On 07.12.2021 10:24, mark maker wrote:

> Hi Jan

>

> OpenPnP can already compress the Gcode:

>

> 2. Remove whitespace and unnecessary trailing digits

> https://github.com/openpnp/openpnp/wiki/GcodeAsyncDriver#gcodedriver-new-settings

> 3. You can set the resolution on the Axis, i.e. if you set it to 0.01

> you get what you describe.

>

> All this was used in my tests with regular Smoothie and Duet 3 to no avail.

>

> There is currently no support for relative motion. That would probably

> help a bit here, but create other problems.

>

> Regular Smoothie has not enough RAM, I was able to increase the queue to

> 48 before it stopped working. But that's not enough. For fully smoothed

> operation you probably need 100-300 segments. Regular Smoothie has very

> fast native USB serial and flow control, but I still don't know whether

> it would be fast enough.

>

> > //Would that provide enough speed and space for smooth motion blending?/

> The CHM-T36VA serial bridge to the STM32F407 is slow and shaky, flow

> control seemed not to work properly. Experiments, I think done by Nélio,

> did not work. Maybe there would be an option to connect native USB serial?

>

> Duet 3 seems to have enough RAM, but its serial USB serial, while being

> improved lately, is still way too slow. The last experiments (I think by

> Wolfgang) did not really work out.

>

> One problem is also to let the planner wait until it has received the

> whole sequence for look-ahead planning. If the planner starts

> planning/executing motion too quickly, it will rush into premature

> deceleration, not yet seeing the sequence to the end. We added some new

> grace period support to Duet, i.e. it would wait longer, or until an

> M400 is received, which typically signals the end of a sequence. I'm not

> sure we tested the latest incarnation of that. Any controller supporting

> such paths would have a grace period+release feature too.

>

> Here is a simulations with the OpenPnP Motion Planner (dual nozzle

> machine, i.e. see the nozzle switch in the back row, showing as inverted

> Z moves):

>

>

>

>> >> <mailto:openpnp+u...@googlegroups.com

>> <mailto:openpnp%2Bunsu...@googlegroups.com>>.

>> >>

>> https://groups.google.com/d/msgid/openpnp/000301d7e7ec%24f641e250%24e2c5a6f0%24%40gmail.com

>> >>

>> <https://groups.google.com/d/msgid/openpnp/000301d7e7ec%24f641e250%24e2c5a6f0%24%40gmail.com?utm_medium=email&utm_source=footer

>> <https://groups.google.com/d/msgid/openpnp/000301d7e7ec%24f641e250%24e2c5a6f0%24%40gmail.com?utm_medium=email&utm_source=footer>>.

>> >>

>> >>

>> >>

>> >> --

>> >>

>> >> 勇気とユーモア

>> >>

>> >> --

>> >> You received this message because you are subscribed to the

>> >> Groups "OpenPnP" group.

>> >> To unsubscribe from this group and stop receiving emails

>> from it,

>> >> send an email to openpnp+u...@googlegroups.com

>> >> <mailto:openpnp+u...@googlegroups.com

>> <mailto:openpnp%2Bunsu...@googlegroups.com>>.

>> >>

>> https://groups.google.com/d/msgid/openpnp/CAMHZkm7486hSwqn0zMX4WWKDNLmmpT4J5w%2BQq%2BjtH5MO7yr6Yg%40mail.gmail.com

>> >>

>> <https://groups.google.com/d/msgid/openpnp/CAMHZkm7486hSwqn0zMX4WWKDNLmmpT4J5w%2BQq%2BjtH5MO7yr6Yg%40mail.gmail.com?utm_medium=email&utm_source=footer

>> <https://groups.google.com/d/msgid/openpnp/CAMHZkm7486hSwqn0zMX4WWKDNLmmpT4J5w%2BQq%2BjtH5MO7yr6Yg%40mail.gmail.com?utm_medium=email&utm_source=footer>>.

>> >

>> > --

>> > You received this message because you are subscribed to the

>> > Groups "OpenPnP" group.

>> > To unsubscribe from this group and stop receiving emails

>> from it,

>> > send an email to openpnp+u...@googlegroups.com

>> > <mailto:openpnp+u...@googlegroups.com

>> <mailto:openpnp%2Bunsu...@googlegroups.com>>.

>> >

>> https://groups.google.com/d/msgid/openpnp/c07eaf9c-018d-f342-7437-fb23c3a9eafb%40makr.zone

>> >

>> <https://groups.google.com/d/msgid/openpnp/c07eaf9c-018d-f342-7437-fb23c3a9eafb%40makr.zone?utm_medium=email&utm_source=footer

>> <https://groups.google.com/d/msgid/openpnp/c07eaf9c-018d-f342-7437-fb23c3a9eafb%40makr.zone?utm_medium=email&utm_source=footer>>.

>> >

>> >

>> >

>> > --

>> >

>> > 勇気とユーモア

>> >

>> > --

>> > You received this message because you are subscribed to the Google

>> > Groups "OpenPnP" group.

>> > To unsubscribe from this group and stop receiving emails from

>> it, send

>> > an email to openpnp+u...@googlegroups.com

>> > <mailto:openpnp+u...@googlegroups.com

>> <mailto:openpnp%2Bunsu...@googlegroups.com>>.

>> >

>> https://groups.google.com/d/msgid/openpnp/CAMHZkm4qt8QO4qBTg%2B9uci7C21LDdoX1Utoqnwny9nvAEoaf%3DA%40mail.gmail.com

>>

>> >

>> <https://groups.google.com/d/msgid/openpnp/CAMHZkm4qt8QO4qBTg%2B9uci7C21LDdoX1Utoqnwny9nvAEoaf%3DA%40mail.gmail.com?utm_medium=email&utm_source=footer

>> <https://groups.google.com/d/msgid/openpnp/CAMHZkm4qt8QO4qBTg%2B9uci7C21LDdoX1Utoqnwny9nvAEoaf%3DA%40mail.gmail.com?utm_medium=email&utm_source=footer>>.

>>

>> --

>> You received this message because you are subscribed to the Google

>> Groups "OpenPnP" group.

>> To unsubscribe from this group and stop receiving emails from it,

>> send an email to openpnp+u...@googlegroups.com

>>

>>

>>

>> --

>>

>> 勇気とユーモア

>>

>> --

>> You received this message because you are subscribed to the Google

>> Groups "OpenPnP" group.

>> To unsubscribe from this group and stop receiving emails from it, send

>> an email to openpnp+u...@googlegroups.com.

>> To view this discussion on the web visit

>> https://groups.google.com/d/msgid/openpnp/CAMHZkm4Lz%3DdHzfzpuBB1AVXXwzS1zNKo%3DD4DtqNX_mVqu_2c1g%40mail.gmail.com

> --

> You received this message because you are subscribed to the Google

> Groups "OpenPnP" group.

> To unsubscribe from this group and stop receiving emails from it, send

> an email to openpnp+u...@googlegroups.com

> <mailto:openpnp+u...@googlegroups.com>.

> To view this discussion on the web visit

> <https://groups.google.com/d/msgid/openpnp/5de9fc16-a24b-bf0c-1838-a9a2abf74745%40makr.zone?utm_medium=email&utm_source=footer>.

mark maker

> flow-control is not needed.

This is not usually true. It takes considerable time to interpret

the G-code, put the motion segments in the queue, and plan the

ramps. These controllers are usually simple in that they always

re-plan everything after receiving a new motion segment. Also

there is usually no such thing as multi-threading and/or smart

queue locking, this stuff is done in interrupt handlers that do

one whole thing at a time. This means that

locking/blocking times are large, the serial receive buffer can

overflow and it must be flow controlled.

And that is also what was observed on every controller

so far: unless flow control is done right, you get erratic

behaviour or even hangs.

> a) I've read that USB interfaces might cause trouble because of ground loops.

That's the same for serial. It won't work without either

isolation or grounding.

> Yes, USB isolators are easy to add.

Yes, and IMHO they are a MUST for any fast NC machine. My Azteeg

Smoothie clone controller has one built-in, as it should.

> b) Fitting USB-serial into the existing firmware would be some work and - to my understanding - only make sense if we would gain significant benefits.

These gains would certainly be significant. We're talking a whole

different category of performance!

> why not try to optimize the queue/memory layout...

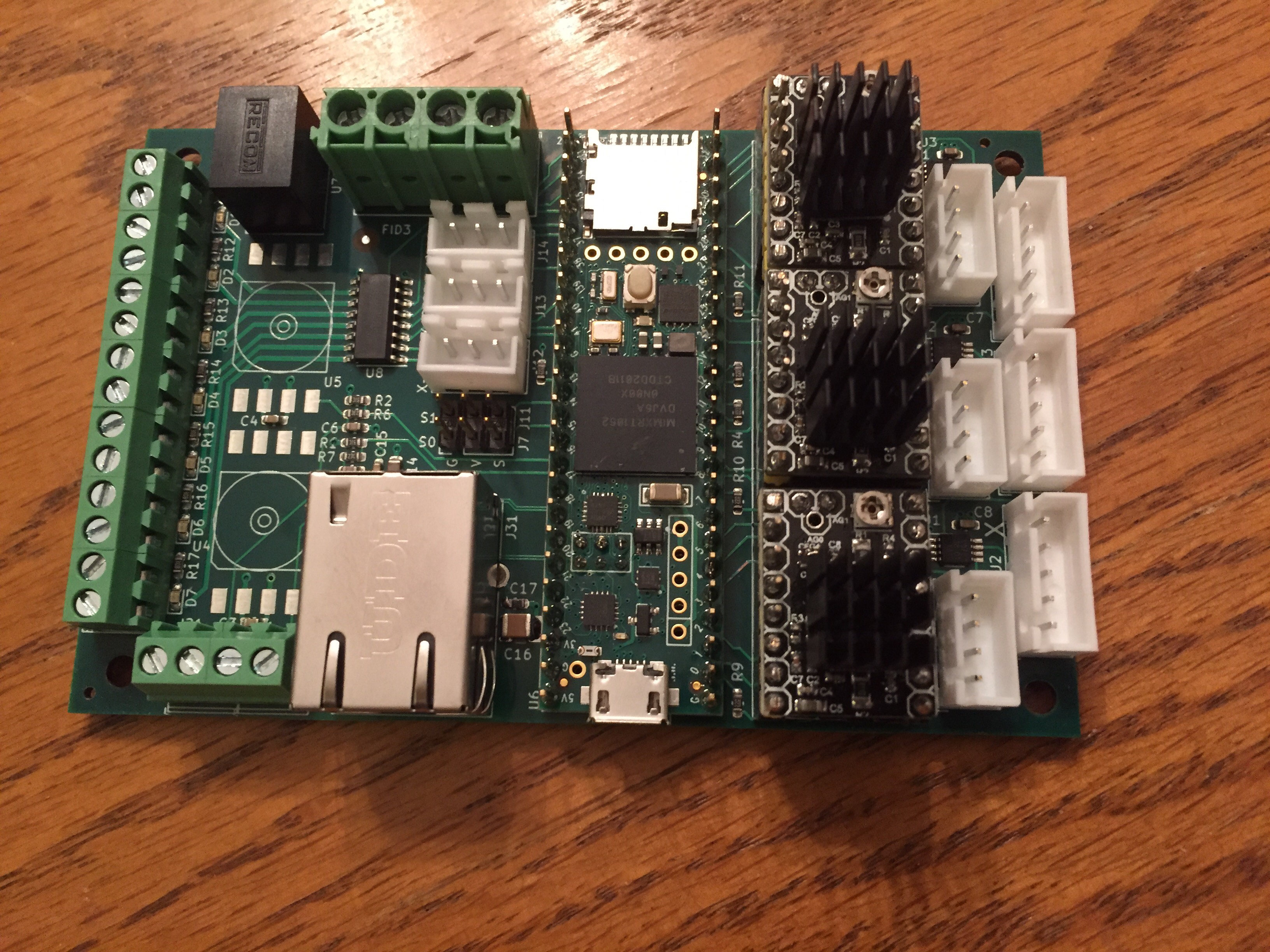

Improving the comms speed or enlarging the queue is just treating the symptoms. Like I said: the real solution IMHO lays in supporting that stuff natively on the controller. Support motion blending (G64) and true 7-segment 3rd order control. But I would go for a more performant MCU, like the Teensy 4.1 and a separate driver board, like @billsef did:

https://github.com/bilsef/teensy4_pnp_controller

https://groups.google.com/g/openpnp/c/79hyOIzmnxY/m/Bczl2T3QAgAJ

_Mark

Jan

On 08.12.2021 08:29, mark maker wrote:

[...]

> /> //why not try to optimize the queue/memory layout... /

> Improving the comms speed or enlarging the queue is just treating the

> symptoms. Like I said: the real solution IMHO lays in supporting that

> stuff natively on the controller. Support motion blending (G64) and true

> 7-segment 3rd order control. But I would go for a more performant MCU,

> like the Teensy 4.1 and a separate driver board, like @billsef did:

>

queue. Unfortunately I got stuck. After changing the memory layout (to

free AHB0 as much as possible) I had to change MemoryPool.cpp to allow

Soothieware to handle pools larger then 64k. How I've 128k AHB0 pool,

but can't get the queue large because there is still more memory

consumped on the heap per queue element the on AHB0. Would anybody

please solve the puzzle for me:

- planner_queue_size is evaluated in Conveyor.cpp (line 75) and hand

over (in line 83) to BlockQueue::resize() (line 157).

- In BlockQueue::resize() memory for the queue is allocated at line 184

on AHB0 pool and then used to create "newring".

- If I change planner_queue_size by 1, I can see that AHB0 usage

increases by "Block size". In addition I see, that the heap usage

increases by 400 byte. Why?

b) I've studied the Nist RS274 Version 3 specification and found

(section 4.3.5.3) that Smoothieware currently seems to use mode

CANON_EXACT_PATH. G64 would switch to mode CANON_CONTINUOUS. If I

understand the specification correctely this would mean, that corners

are rounded to a configurable max. deviation. Together with my

understanding for junction_deviation this sound to me as if mode

CANON_CONTINUOUS could be implemented by providing a second

junction_deviation parameter. For CANON_CONTINUOUS we use a larger (eg.

5mm) junction deviation and for CANON_EXACT_PATH the current small one.

I'm I missing something?

c) implementing 7-segment 3rd order control would be an other (separate)

task.

Jan

[...]

> <https://groups.google.com/d/msgid/openpnp/6a6d5fe2-0ff4-ff22-fbe9-8aa5c5e5d66a%40makr.zone?utm_medium=email&utm_source=footer>.

mark maker

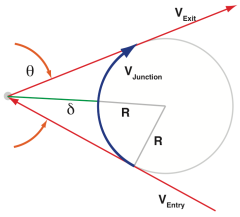

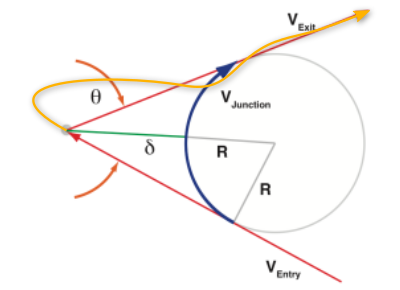

junction_deviation that is currently Grbl is not to be confused with real curving. The Grbl junction_deviation pretends that there is a "virtual" curve, but does not actually make one. This is an optimization so the machine does not have to decelerate to zero velocity in junctions, instead it pretends there is a curve and therefore can move through the corner at speed. This is only tolerable because the machine and the motors (electromagnetic fields) are flexible to a degree, they will just be banged through. AFAIK, for stepper motors it can only tolerate deviations that don't threaten to lose steps, i.e. in the order of a half-step, typically sub-millimeter.

https://onehossshay.wordpress.com/2011/09/24/improving_grbl_cornering_algorithm/

"Lastly, keep in mind this method is a virtual path deviation that is only used for robustly computing the junction speed and does not actually mean there is a physical path deviation in your CNC machine."

To plan true physical curves would be an altogether different

matter.

_Mark

Arthur Wolf

junction_deviation that is currently Grbl is not to be confused with real curving. The Grbl junction_deviation pretends that there is a "virtual" curve, but does not actually make one. This is an optimization so the machine does not have to decelerate to zero velocity in junctions, instead it pretends there is a curve and therefore can move through the corner at speed. This is only tolerable because the machine and the motors (electromagnetic fields) are flexible to a degree, they will just be banged through. AFAIK, for stepper motors it can only tolerate deviations that don't threaten to lose steps, i.e. in the order of a half-step, typically sub-millimeter.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/481bc813-d230-d7c3-0e66-d8b882cd39f3%40makr.zone.

--

勇気とユーモア

mark maker

> This is obvious if you have a flimsy machine, high acceleration and strong junction deviation, you'll see the machine "rock" as the inertia from the movement is transferred to the frame.

> If however your machine is very sturdy, that energy is transformed in other ways: heat, sound etc. This is one reason why more expensive machines tend to be heavier/have sturdier frames

I do agree that heavier, stiffer machines with the corresponding

much more powerful motors to drive the heavier rig, do allow for

higher accelerations, while retaining positioning accuracy.

But I'm not sure it is actually an advantage in terms of

allowable pretend junction deviation: If the machine does

not give way, this means that exceedingly higher accelerations

(and jerk etc.) will take place. Acceleration/jerk are obtained by

essentially dividing the momentum by the flex, i.e. a

machine with near zero flex would have near infinite

acceleration/jerk, i.e. no motor can hold that! Of course, if you

have closed loop servos, it will correct any deviation after the

fact, but then your stiffness and accuracy is effectively

gone too, and you might get ringing, again due to the stiffness.

A flimsier/softer machine might take these deviations more

"naturally". It will just give way and ride through the bumps like

on suspension, with a lot of damping too. Even with open loop

steppers it remains practicable. Every cheap but still damn good

3D printer is a testimony of that balance, that after years of

tuning may be "just right". This sometimes becomes visible, such

as

when Thomas Sanladerer "upgrades" his PRUSA with linear rails,

making it much stiffer, and then sees how the prints get worse,

not better. I'm sure that true motion blending (instead of

just pretend junction deviation) could make that ringing

go away.

So I would say that a stiffer machine does not necessarily

benefit less from advanced motion control (like true

motion blending), it may sometimes even be the other way around.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAMHZkm7o1Ydz9%3DXBppV1fynRL9dx1e7zhr_kYXO3_qokFhiUJA%40mail.gmail.com.

Harjit Singh

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/d0a0ca6e-ced6-856b-c768-6f5ab32218e5%40makr.zone.

mark maker

Hi Harjit,

The way I did it in OpenPnP is linked below. The idea

is somewhat described in the comment here.

But today/in a controller I would probably do it differently. Rather than "overshoot" into an uncoordinated move at Safe Z, I would follow the G64 idea/NIST standard, to smooth one motion into the next, i.e. not necessarily reach the corner point.

Code parts:

Single Motion (interface to use):

https://github.com/openpnp/openpnp/blob/develop/src/main/java/org/openpnp/model/Motion.java

Single Motion Profile (3rd order ramps, uncoordinated moves etc.). That's the hardest part:

https://github.com/openpnp/openpnp/blob/develop/src/main/java/org/openpnp/model/MotionProfile.java

Motion Path (Handling multiple Motions, putting things together):

Motion Planner (interface to use the whole thing): https://github.com/openpnp/openpnp/blob/develop/src/main/java/org/openpnp/machine/reference/driver/ReferenceAdvancedMotionPlanner.java_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAEm8oET_%3DJW_M%3DZAUW1g69MMPqJ4usA8RT7is49bJccEUNLvPg%40mail.gmail.com.

Jarosław Karwik

Jan

I'm sorry, I still don't get it.

Mark, you asked for controller-wise motion blending and referred to

G64. Section 3.5.14 of the NIST specification version 3 says, that G64

"put the machining center into [..] continuous mode". Continuous mode is

explained in Section 4.3.5.3 as "In CANON_CONTINUOUS mode, the control

tries to keep the feed rate constant and does not try to keep the

controlled point exactly on the path at all times.". In addition is

specifies that "There is a maximum allowable deviation at such

junctures, and the control should never allow that to be exceeded;

acceleration and deceleration may be performed if necessary to do this."

I've studies the (smoothieware) code and Sonny's paper you mentioned.

To my understanding the math is ok and the assumption, that the junction

is a cycle even if it its not, holds true. (Calculating the difference

would be a nice homework for graduates.)

I also don't see why inertia, machine friction and step loosing is

always argued against junction_deviation. To my understanding

junction_deviation, as proposed by Sonny and implemented in

smoothieware, tries to join two segments of a movement by starting the

second while the first it still ongoing by respecting a maximum

allowable path deviation. Each segment follows its own rules with

respect to target position, max. speed and max. acceleration (and

potential other parameters). Suppose the implementation is correct, no

motor is ever operated outside its specified limits. However, in such

junctions, two or more motors may operate in parallel hence the net

acceleration (at the nozzle tip in the PnP case) is larger. (for a

square machine - as we usually use for PnP - this is sqrt(a_x^2 + a_y^2

+ a_z^2) where a_i is the acceleration on the respective axis).

If you don't like the way the machine drives thru junctions, you're

free to ask if the acceleration profile in junctions could be made

different from the one used to stop the motor. At present the

(smoothieware) implementation uses constant ac-/deceleration. I guess

thats what you meant by 7-segment motion control. That would probably

change the way, the machine drives thru corners, but will not give a

circular motion (sin/cos)... If you don't like the effect of the net

acceleration it should be straight forward to reduce the configured

acceleration per axis in corners. However, this would be beyond the

scope the the NIST specification.

To my understanding, with junction_deviation enabled the machine runs

in continuous mode. You would then need G61 to switch the machine to

exact path mode or G61.1 for exact stop mode to force the machine to

reach certain points exactly. Btw: did you ever observed, that the

nozzle did not touch down enough (on feeders or the PCB)? With

junction_deviation > 0 and nozzle-down and nozzle-up segments both in

the queue, the machine would be allowed to only lower the nozzle by

target-Z - junction_deviation (remember continuous mode: "There is a

maximum allowable deviation at such junctures"). So I would say, we need

a way to put the controller into exact path mode where application and

use junction_deviation every where else. We could then reduce jerk by

modifying the acceleration/deceleration functions in the controller.

Maybe S-shape using sin/cos would be a way to go, thats not so difficult

the implement. Unfortunately it only provides a single parameters as we

currently have. So acceleration would be converted into angular velocity.

Jan

On 11.12.2021 14:28, mark maker wrote:

> /> This is obvious if you have a flimsy machine, high acceleration and

>

> />//If however your machine is very sturdy, that energy is transformed

> I do agree that heavier, stiffer machines with the corresponding much

> more powerful motors to drive the heavier rig, do allow for higher

> accelerations, while retaining positioning accuracy.

>

> But I'm not sure it is actually an advantage in terms of allowable

> infinite acceleration/jerk, i.e. no motor can hold that! Of course, if

> you have closed loop servos, it will correct any deviation after the

>

> A flimsier/softer machine might take these deviations more "naturally".

> It will just give way and ride through the bumps like on suspension,

> with a lot of damping too. Even with open loop steppers it remains

> practicable. Every cheap but still damn good 3D printer is a testimony

> of that balance, that after years of tuning may be "just right". This

> that true motion blending (instead of just /pretend/ junction deviation)

>

> So I would say that a stiffer machine does not necessarily benefit

>

> _Mark

>

> On 11.12.21 13:42, Arthur Wolf wrote:

>>

>>

>> On Sat, Dec 11, 2021 at 10:50 AM mark maker <ma...@makr.zone> wrote:

>>

>> with real curving. The Grbl *junction_deviation* /pretends/ that

>> is an optimization so the machine does not have to decelerate to

>> tolerable because the machine and the motors (electromagnetic

>> fields) are flexible to a degree, they will just be banged

>> through. AFAIK, for stepper motors it can only tolerate deviations

>> that don't threaten to lose steps, i.e. in the order of a

>> half-step, typically sub-millimeter.

>>

>>

>> One way to think about this, is the less you slow down (in a corner or

>> otherwise), the more inertia from the movement is transformed into

>> kinetic energy, that has to be absorbed by the system (motors, frame,

>> slack in belts, springs, etc)

>> This is obvious if you have a flimsy machine, high acceleration and

>> strong junction deviation, you'll see the machine "rock" as the

>> inertia from the movement is transferred to the frame.

>> If however your machine is very sturdy, that energy is transformed in

>> other ways: heat, sound etc. This is one reason why more expensive

>> machines tend to be heavier/have sturdier frames: it allows for higher

>> speeds/accelerations/jd without the machine shaking all around

>> (loosing precision).

>>

>> I had actually started work on a planner for Smoothie that limits

>> acceleration/jd in terms of explicit energy, so you'd say something

>> like "my frame can take 0.1 joules per second", and it'd limit changes

>> in speed/direction to accommodate that. I hope I'll finish that someday.

>>

>>

>> /"//Lastly, keep in mind this method is a //*virtual*// path

>> speed and does not actually mean there is a physical path

>>>>>>> >> <mailto:openpnp+u...@googlegroups.com

>>>>>>> <mailto:openpnp+u...@googlegroups.com>

>>>>>>> <mailto:openpnp%2Bunsu...@googlegroups.com>

>>>>>>> >> To view this discussion on the web visit

>>>>>>> >>

>>>>>>> https://groups.google.com/d/msgid/openpnp/000301d7e7ec%24f641e250%24e2c5a6f0%24%40gmail.com

>>>>>>>

>>>>>>> >>

>>>>>>> <https://groups.google.com/d/msgid/openpnp/000301d7e7ec%24f641e250%24e2c5a6f0%24%40gmail.com?utm_medium=email&utm_source=footer

>>>>>>> <https://groups.google.com/d/msgid/openpnp/000301d7e7ec%24f641e250%24e2c5a6f0%24%40gmail.com?utm_medium=email&utm_source=footer>

>>>>>>> <https://groups.google.com/d/msgid/openpnp/000301d7e7ec%24f641e250%24e2c5a6f0%24%40gmail.com?utm_medium=email&utm_source=footer>

>>>>>>> <https://groups.google.com/d/msgid/openpnp/000301d7e7ec%24f641e250%24e2c5a6f0%24%40gmail.com?utm_medium=email&utm_source=footer>>.

>>>>>>>

>>>>>>> >>

>>>>>>> >>

>>>>>>> >>

>>>>>>> >> --

>>>>>>> >>

>>>>>>> >> 勇気とユーモア

>>>>>>> >>

>>>>>>> >> --

>>>>>>> >> You received this message because you are

>>>>>>> subscribed to the

>>>>>>> >> Groups "OpenPnP" group.

>>>>>>> >> To unsubscribe from this group and stop receiving

>>>>>>> emails

>>>>>>> from it,

>>>>>>> >> send an email to openpnp+u...@googlegroups.com

>>>>>>> <mailto:openpnp%2Bunsu...@googlegroups.com>

>>>>>>> >> <mailto:openpnp+u...@googlegroups.com

>>>>>>> <mailto:openpnp+u...@googlegroups.com>

>>>>>>> <mailto:openpnp%2Bunsu...@googlegroups.com>

>>>>>>> >> To view this discussion on the web visit

>>>>>>> >>

>>>>>>> https://groups.google.com/d/msgid/openpnp/CAMHZkm7486hSwqn0zMX4WWKDNLmmpT4J5w%2BQq%2BjtH5MO7yr6Yg%40mail.gmail.com

>>>>>>>

>>>>>>> >>

>>>>>>> <https://groups.google.com/d/msgid/openpnp/CAMHZkm7486hSwqn0zMX4WWKDNLmmpT4J5w%2BQq%2BjtH5MO7yr6Yg%40mail.gmail.com?utm_medium=email&utm_source=footer

>>>>>>> <https://groups.google.com/d/msgid/openpnp/CAMHZkm7486hSwqn0zMX4WWKDNLmmpT4J5w%2BQq%2BjtH5MO7yr6Yg%40mail.gmail.com?utm_medium=email&utm_source=footer>

>>>>>>> <https://groups.google.com/d/msgid/openpnp/CAMHZkm7486hSwqn0zMX4WWKDNLmmpT4J5w%2BQq%2BjtH5MO7yr6Yg%40mail.gmail.com?utm_medium=email&utm_source=footer>

>>>>>>> <https://groups.google.com/d/msgid/openpnp/CAMHZkm7486hSwqn0zMX4WWKDNLmmpT4J5w%2BQq%2BjtH5MO7yr6Yg%40mail.gmail.com?utm_medium=email&utm_source=footer>>.

>>>>>>>

>>>>>>> >

>>>>>>> > --

>>>>>>> > You received this message because you are

>>>>>>> subscribed to the

>>>>>>> > Groups "OpenPnP" group.

>>>>>>> > To unsubscribe from this group and stop receiving

>>>>>>> emails

>>>>>>> from it,

>>>>>>> > send an email to openpnp+u...@googlegroups.com

>>>>>>> <mailto:openpnp%2Bunsu...@googlegroups.com>

>>>>>>> > <mailto:openpnp+u...@googlegroups.com

>>>>>>> <mailto:openpnp+u...@googlegroups.com>

>>>>>>> <mailto:openpnp%2Bunsu...@googlegroups.com>

>>>>>>> > To view this discussion on the web visit

>>>>>>> >

>>>>>>> https://groups.google.com/d/msgid/openpnp/c07eaf9c-018d-f342-7437-fb23c3a9eafb%40makr.zone

>>>>>>>

>>>>>>> >

>>>>>>> <https://groups.google.com/d/msgid/openpnp/c07eaf9c-018d-f342-7437-fb23c3a9eafb%40makr.zone?utm_medium=email&utm_source=footer

>>>>>>> <https://groups.google.com/d/msgid/openpnp/c07eaf9c-018d-f342-7437-fb23c3a9eafb%40makr.zone?utm_medium=email&utm_source=footer>

>>>>>>> <https://groups.google.com/d/msgid/openpnp/c07eaf9c-018d-f342-7437-fb23c3a9eafb%40makr.zone?utm_medium=email&utm_source=footer>

>>>>>>> <https://groups.google.com/d/msgid/openpnp/c07eaf9c-018d-f342-7437-fb23c3a9eafb%40makr.zone?utm_medium=email&utm_source=footer>>.

>>>>>>>

>>>>>>> >

>>>>>>> >

>>>>>>> >

>>>>>>> > --

>>>>>>> >

>>>>>>> > 勇気とユーモア

>>>>>>> >

>>>>>>> > --

>>>>>>> > You received this message because you are subscribed to

>>>>>>> the Google

>>>>>>> > Groups "OpenPnP" group.

>>>>>>> > To unsubscribe from this group and stop receiving

>>>>>>> emails from

>>>>>>> it, send

>>>>>>> > an email to openpnp+u...@googlegroups.com

>>>>>>> <mailto:openpnp%2Bunsu...@googlegroups.com>

>>>>>>> > <mailto:openpnp+u...@googlegroups.com

>>>>>>> <mailto:openpnp+u...@googlegroups.com>

>>>>>>> <mailto:openpnp%2Bunsu...@googlegroups.com>

>>

>>

>> --

>>

>> 勇気とユーモア

>>

>> --

>> You received this message because you are subscribed to the Google

>> Groups "OpenPnP" group.

>> To unsubscribe from this group and stop receiving emails from it, send

>> <https://groups.google.com/d/msgid/openpnp/CAMHZkm7o1Ydz9%3DXBppV1fynRL9dx1e7zhr_kYXO3_qokFhiUJA%40mail.gmail.com?utm_medium=email&utm_source=footer>.

> --

> You received this message because you are subscribed to the Google

> Groups "OpenPnP" group.

> To unsubscribe from this group and stop receiving emails from it, send

> an email to openpnp+u...@googlegroups.com

> <mailto:openpnp+u...@googlegroups.com>.

> To view this discussion on the web visit

> <https://groups.google.com/d/msgid/openpnp/d0a0ca6e-ced6-856b-c768-6f5ab32218e5%40makr.zone?utm_medium=email&utm_source=footer>.

mark maker

Hi Jan

Sorry, what you are describing is not what junction_deviation does in Grbl and descendants, including Smoothie.

These controllers are only capable of planning straight lines. Even if you send them G2, G3 arcs, they internally break it up into a polygon. The planner can only handle straight segments.

Now imagine sitting in one of these small mining rail cars. You

are driving at speed through a curve in the rails. Now imagine the

rails are not smooth but approximated by a polygon. Certainly you

can now "feel" the jerks and bumps in your imagination 😁

When driving over a polygon corner, even at a very shallow angle,

the rail car would need to change its velocity (vector) in zero

time. Due to inertia, that is physically impossible.

Instead everything in and on it will flex, including you. Ouch,

right?!

The remove all jerking and bumping, you would need to decelerate

to zero velocity before the corner. Then re-accelerate again after

the corner. Obviously this is very slow and unacceptable for many

NC application. You'd burn a mill's drill bit, shoot big holes

with a laser, or make blobs with a 3D printer.

So these controllers make a compromise. They pretend there is a curve through the corner. Then they calculate what speed would be acceptable to go through the corner, if there were such a curve (limited by the acceleration). The shallower the corner angle, the faster they can go through. Then they calculate the segment entry/exit speeds according to that speed. But they still drive the steppers in straight lines (red vectors). This junction_deviation does not remove the "jerk or bump" when going through the corner, it only limits it to a tolerable amount!

That's why these are called virtual curves. They are not real!

https://onehossshay.wordpress.com/2011/09/24/improving_grbl_cornering_algorithm/

In reality the machine will not move along that dark blue virtual

curve, instead it will move something like the

orange curve here,

i.e. overshoot and then settle back onto the exit vector. It's all

in the flex and dampening of the machine:

Obviously it would be much less extreme on a shallow angle, and

that's what interpolation, including OpenPnP's tries to

do. This is OK for many applications, on the sub-millimeter scale

and with mostly shallow polygon angles, but it is in no way

motion path smoothing or G64.

Therefore, unfortunately what you are describing in the rest of your text "does not compute". 😬

If you don't believe me: set your Smoothie junction_deviation

to some multi-millimeter value:

https://smoothieware.org/configuration-options

| junction_deviation | 0.05 | Similar to the old “max_jerk”, in millimeters. Defines how much the machine slows down when decelerating proportional to the vector angle of change of direction. See here and here. Lower values mean being more careful, higher values means being faster and have more jerk |

Try running a simple two-legged angled move. But no guarantees as to the survival of your machine!!!

_Mark

Jan

Many thanks for putting so much effort in OpenPnP and in responding to

my questions.

I've studied the code again together with your (very helpful)

explanations and I now understand where I was wrong: the Block class

describes a linear movement of all motors together. So if two blocks are

joined, the code can only control the speed at the junction. And thats

where it might violate the acceleration limits per axis which would

introduce additional jerk and potentially result in loss of steps.

I've also found the place, there the slicing of arcs into line segments

is done.

Overall, it seems that adding mode CANON_CONTINUOUS (motion blending)

would be quite some work and probably would require making some

fundamental changes. As you wrote earlier, according to your simulations

the benefit of such modification is only limited (and you already have a

solutions with PC wise motion blending), I'll put my efforts rather into

the job optimization topic we discussed as well.

Jan

On 14.12.2021 18:08, mark maker wrote:

> Hi Jan

>

>

> These controllers are only capable of planning straight lines. Even if

> you send them G2, G3 arcs, they internally break it up into a polygon.

> Now imagine sitting in one of these small mining rail cars. You are

> driving at speed through a curve in the rails. Now imagine the rails are

> not smooth but approximated by a polygon. Certainly you can now "feel"

> the jerks and bumps in your imagination 😁

>

> When driving over a polygon corner, even at a very shallow angle, the

> rail car would need to change its velocity (vector) in zero time. Due to

> it will flex, including you. *Ouch*, right?!

> The remove all jerking and bumping, you would need to decelerate to zero

> velocity before the corner. Then re-accelerate again after the corner.

> Obviously this is very slow and unacceptable for many NC application.

> You'd burn a mill's drill bit, shoot big holes with a laser, or make

> blobs with a 3D printer.

>

> to go through the corner, if there were such a curve (limited by the

> acceleration). The shallower the corner angle, the faster they can go

> through. Then they calculate the segment entry/exit speeds according to

> vectors). *This *junction_deviation* does *not remove* the "jerk or

> bump" when going through the corner, it *only limits it to a tolerable

> amount*!

>

> That's why these are called *virtual curves*. They are *not real!*

>

> **

>

> https://onehossshay.wordpress.com/2011/09/24/improving_grbl_cornering_algorithm/

>

> In reality the machine will not move along that*dark blue **virtual

> **curve*, instead it will move something like the *orange **curve* here,

> the flex and dampening of the machine:

>

> Therefore, unfortunately what you are describing in the rest of your

> text "does not compute". 😬

>

>

> https://smoothieware.org/configuration-options

>

> junction_deviation 0.05 Similar to the old “max_jerk”, in millimeters.

> Defines how much the machine slows down when decelerating proportional

> to the vector angle of change of direction. See here

> <https://github.com/grbl/grbl/wiki/Configuring-Grbl-v0.8>. Lower values

> jerk

>

> the survival of your machine!!! *

> <https://groups.google.com/d/msgid/openpnp/bf59b8d3-f927-4c05-aa1c-aaf35b045373%40makr.zone?utm_medium=email&utm_source=footer>.

dc42

1. If the starting Z is lower than the ending Z, go straight up to reach the ending Z.

bert shivaan

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/0aa51ae4-a0b8-4ef9-973a-33b59a578d77n%40googlegroups.com.

mark maker

Hi dc42 / all,

this topic had me thinking for quite some time now. The solution

could be something like the following:

- Working assumption: only two subsequent segments can be

blended. A more general, but also much more complicated

discussion could take N blended segments into

consideration, but is beyond the scope here. However, see (16).

- Start by planning the segments as today but no

"junction_deviation" applied (needed modifications are explained

below).

- Instead of executing the motion planner segments one by one,

execute them slightly overlapping in time. See the animation

below. Blending is achieved by simply adding the relative

displacement of the second segment to the absolute

displacement of the first.

- The effects of the overlap (literally, "the cutting of

corners") would have to be limited by the maximum deviation

allowed by G64, as described in the NIST standard. See how

LinuxCNC documents it: http://www.linuxcnc.org/docs/2.6/html/gcode/gcode.html#sec:G64.

- Different accelerations limits on the segments must be taken

into consideration, i.e. the point in time where the path is

nearest the corner can become very asymmetric (see the demo at

the end).

- The overlap time obtained from (4) is only the theoretical

maximum, it will be further constrained below.

- For very blunt angles this can give large allowable overlap

times.

- Next we need to make sure, the blending still respects the

feed-rate and acceleration limits. This is certainly true for

angles of 90°, nothing is adding up either way.

- For blunter angles, if you take the minimum of the

first segment deceleration ramp time and the second

segment acceleration ramp time as the allowable maximum

overlap time, then the limits should still always be respected

(assuming we allow for the limits to be blended too!).

As one segment ramps down, the other ramps up. The "corner case"

is a sum-zero game, where any deceleration is compensated by

same acceleration, i.e. where the velocity stays constant. This

happens when we blend nearly co-linear segments (with

the same rate limits) together, i.e. we get exactly what we

want: no deceleration in near-straight junctions.

- The limitation to acceleration/deceleration ramp times also

makes sure we always only blend two segments together.

It cannot reach beyond.

- For acute angles, it is more complicated: Deceleration (which

is negative acceleration) and acceleration going in the opposite

direction, get the same sign, i.e. they add up. The axis

acceleration limit could be violated, i.e. the allowable

blending time would be zero.

- But we could alter the segments i.e. limit their

deceleration/acceleration, so that the sum remains within the

axis limit. The most challenged axis would then give the

allowable maximum deceleration/acceleration for the segments.

- Like (9) we limit the overlap to the smaller ramp time.

- Unfortunately similar to (9), the ramp times can be different

in the two segments. So the optimal planner would have

to plan with two deceleration or acceleration ramp

phases, one that is constrained by overlap and one that is not.

I guess that would actually be the most difficult part of the

whole impementation. Especially for 3rd order (jerk) control.

- The above steps were explained in a logical order. But in reality, they would have to be done in a different order, i.e. steps (12) through (14) would have to precede step (2).

- Corner case: We assume (2) optimizes co-linear segments as it

already does in typical planners today. More specifically, we

assume its makes sure the ramp of (at least) one co-linear

segment becomes one-sided. Because there is no ramp time, (9)

and (13) will naturally disallow blending of co-linear

segments. These are not generally OK for blending, because they

have entry/exit velocity that is non-zero. By excluding those,

we only have to deal with segments that decelerate/accelerate

to/from still-stand, so what was said in (9) still holds true.

Furthermore, this co-linear segment optimization covers

N subsequent segments, unlike the blending we discuss here (1).

It follows that blending is no generalization, i.e. no valid

replacement for that optimization (as I was hoping for some

time).

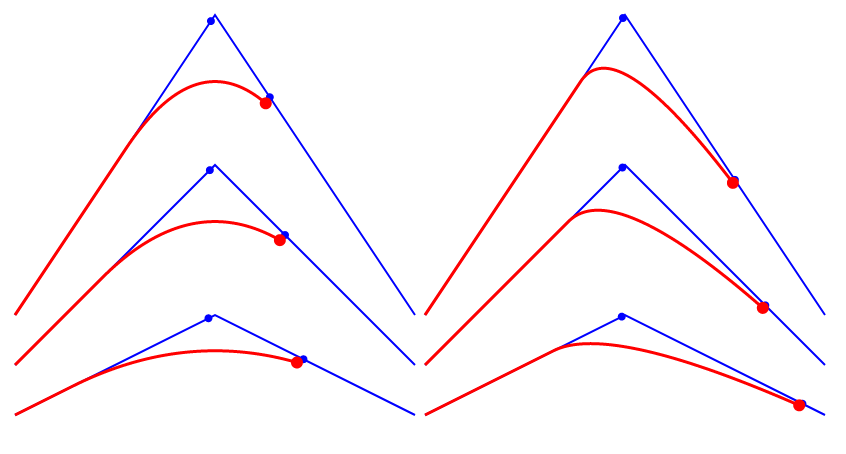

See the animation (click to open):

https://makr.zone/motion_blending_animation.html

It has a higher acceleration on the second segment to demonstrate

that G64 calculation is not trivial (5). But note that the demo

simply has the same overlap time for all the examples, i.e. there

is no "real G64" applied.

_Mark

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/0aa51ae4-a0b8-4ef9-973a-33b59a578d77n%40googlegroups.com.

mark maker

Added both symmetric and asymmetric acceleration for better illustration:

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/f4ace535-fbb4-cb07-0177-462dbb0fdd01%40makr.zone.

John Plocher

High precision stepper movement. Klipper utilizes an application processor (such as a low-cost Raspberry Pi) when calculating printer movements. The application processor determines when to step each stepper motor, it compresses those events, transmits them to the micro-controller, and then the micro-controller executes each event at the requested time. Each stepper event is scheduled with a precision of 25 micro-seconds or better. The software does not use kinematic estimations (such as the Bresenham algorithm) - instead it calculates precise step times based on the physics of acceleration and the physics of the machine kinematics. More precise stepper movement translates to quieter and more stable printer operation.

Klipper uses an "iterative solver" to calculate precise step times from simple kinematic equations. This makes porting Klipper to new types of robots easier and it keeps timing precise even with complex kinematics (no "line segmentation" is needed).

Jarosław Karwik

mark maker

Hi John,

Conceptually, this is certainly a possible approach.I don't know if Klipper specifically is a valid approach

for OpenPnP, because it seems to address use cases that are

different. In 3D Printing or CNC Milling etc. you have a

NC-Program that is prepared from beginning to end. It then statically

runs for hours.

This means that latency is of no concern whatsoever.

However, in OpenPnP we have a highly interactive system: Vision,

Vacuum Sensing, Contact Probing, Drag-pin sensing, Feeder sensing

etc. are all sensory inputs that are interpreted by OpenPnP, and

subsequent G-code can only be generated with the knowledge

obtained from that sensory input. Because of that, OpenPnP runs in

close step-by-step synchronization with the controller. I improved

that a bit by introducing the GcodeAsyncDriver, but at

least in case of vision, the round-trip time is still very

important.

There has been talk about Klipper before. A user said it has 100ms latency, which would not be catastrophic but still bad. Unfortunately, that conversation was deleted by the user.

_Mark

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/7a5a74d4-3f39-453b-b1b2-4d06921a2383n%40googlegroups.com.

mark maker

Just FIY, I found some mistakes in my reasoning.

Assertions in (8) and (9) about 90° and blunter angles are wrong

in terms of axis limits. For axis limits, the

angle is irrelevant, it is the axis motion flipping its sign

between the two segments that is the relevant criteria.

The angular reasoning is valid for toolpath limits, and

would have to be treated too, similar to what I said before, but

applicable to the toolpath instead of the axis.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/ad49e6f4-61ff-7ad3-7c69-7a7a0c2758ff%40makr.zone.

John Plocher

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/186f92b6-f1f8-16c4-a7b8-6fc578d5e094%40makr.zone.

Harjit Singh

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAKFrckraRqK-zgnAg2RT2sdYEfJh8Z8s1sb8mDDk4ViNLdUnRw%40mail.gmail.com.

mark maker

Hi Harjit,

I assume that the Safe Z promise must be kept. So the curve can only begin at Safe Z, the path must still overshoot into the Safe Z Zone.

The motion planner in OpenPnP would have to determine what the

optimal curve is, given the distance in X, Y and the available

headroom in the Safe Z Zone. For shorter distances in X, Y only a

small overshoot is optimal, i.e. the limit is given by the ramps

of the X/Y move, which then becomes one fluid curve. For large X,

Y moves, you would probably use the full Z head-room, i.e. there

are two curves on either side of a straight move . If the

head-room is large, it also depends on how far down the Z started,

i.e. how fast (and for 3rd order motion, how

accelerated) the nozzle is, when it crosses Safe Z, i.e. how

much head-room it needs to (jerk and) decelerate to still-stand,

i.e. the limit is then given by the Z off-ramp.

Note: if the lifting of Z at the start is not the same as

lowering of Z at the target, the Z overshoot will become

asymmetric. This is especially the case, when we have a dual

nozzle shared Z axis machine, an the other nozzle is

lowered at the target. The Z overshoot is then inverted from the

top of the Safe Z Zone, the resulting move is wave-shaped, instead

of inverted-U-shaped. Is like with the previous method in the

demo's back two rows:

Once the OpenPnP motion planner has the Z overshoot, it can form the curve as follows:

- Sets G64 to zero.

- Moves Z up to Safe Z (first segment).

- Sets G64 to a very large value allowing arbitrary curvature.

- Moves Z further up to start side Z overshoot height (second segment).

- Moves X, Y to target, at target side Z overshoot height (third

segment)

- Moves Z down to Safe Z (fourth segment).

- Sets G64 to zero.

- Moves Z down to target Z (fifth segment).

With the rules (1) and (9)/(13) from my previous post, the

blending/curve can only be between the ramps of two segments. So

breaking up the Z moves, we can make sure that's the case, without

any difficult "reverse G64" calculations on the OpenPnP side.

Overall, this system is much, much simpler than what I've (only partially!) implemented before, i.e. allowing overshoot into uncoordinated moves. Plus, this system seems to conform to the NIST G-code standard. The down side is that the driving system now needs to calculate the overshoot target points. But that's simple in the case of PnP.

https://makr.zone/motion_blending_animation.html_Mark

@mark - to simplify the discussion:

Instead of doing the "upside down U moves" that you have shown, imagine Z axis goes up and down with X and Y at zero velocity i.e. "rectangular" moves.

a) Then compute the time for the X and the Y movement.

b) Then slow down the faster axis to finish at the same time as the slower one by reducing the maximum velocity. This means, we get a movement in a straight line with both axes moving at the same time.

The current controllers that have jerk limited motion can support this. This is slower in that the Z axis motion and the X and Y axis motions aren't blended.

Where I haven't formed a full mental model is around the Z axis blending. I keep thinking, the motion needs to be broken into three segments for the general case:

A) Raise Z to safe Z and accelerate X and Y while ensuring the nozzle/component doesn't crash into an obstruction. At the end of this move, Z will have zero velocity but X and Y will be non-zero.

B) Move X and Y at new motion parameters (max. acceleration, max. velocity and distance).C) Lower Z to target Z and decelerate X and Y to zero while ensuring the nozzle/component doesn't crash into an obstruction. At the end of this move, X, Y and Z will have zero velocity.

Steps #1 and #3 need a 3D path solution. I looked at the code you pointed me to but I got lost because I don't have a mental model of the architecture.

1) Do you compute a "safe Z for when X and Y can start moving" - corresponds to "A" and a "safe Z for when X and Y must not be moving" corresponds to "C"?

____

Jan

On 23.12.2021 09:10, mark maker wrote:

[...]

> Once the OpenPnP motion planner has the Z overshoot, it can form the

> curve as follows:

>

> * Moves Z up to Safe Z (first segment).

> * Sets G64 to a very large value allowing arbitrary curvature.

> * Moves Z further up to start side Z overshoot height (second segment).

> * Moves X, Y to target, at target side Z overshoot height (third segment)

> * Moves Z down to Safe Z (fourth segment).

> * Sets G64 to zero.

> * Moves Z down to target Z (fifth segment).

It looks to me that there is a slight misunderstanding in

CANON_CONTINUOUS mode, which is enabled by G64: According to NIST

standard, "In CANON_CONTINUOUS mode, the control tries to keep the feed

is a maximum allowable deviation at such junctures" and "Currently,

there is no function to set the maximum deviation allowable in

CANON_CONTINUOUS mode."

Therefor your code should

1) configure mode CANON_EXACT_PATH (G61)

2) move to Save Z

3) switch to mode CANON_CONTINUOUS (G64)

4) move to target position (X, Y, Save Z)

5) switch to mode CANON_EXACT_PATH (G61)

6) move Z down to target Z.

The controller should then use what ever path is short, fast and does

not violate "maximum allowable deviation" to go to (X, Y, Save Z).

Implementation wise smoothy/grbl uses a "block" to describe a single

segment of a path. Within this block any motors can be first

accelerated, then run at constant speed and finally decelerate. Hence

the first step would be to break up this schema and allow individual

motor to skip one or more of this steps. This would allow to accelerate

one motor while the other decelerates, which is a basic requirement for

motion blending.

Arthur and others seem to follow a different approach with smoothie2:

provide more space for the motion segment queue, more cpu power for

faster block to block interaction calculation and usb/Ethernet

interfaces for faster communication with OpenPnP. I'm not sure they also

cover the accelerate-one-motor-and-in-parallel-decelerate-an-other

problem which we need for motion blending.

Jan

>> more general, but also much more complicated discussion /could/

>> scope here. However, see (16).

>> below).

>> displacement/ of the second segment to the /absolute displacement/

>> of the first.

>> 4. The effects of the overlap (literally, "the cutting of corners")

>> as described in the NIST standard. See how LinuxCNC documents it:

>> http://www.linuxcnc.org/docs/2.6/html/gcode/gcode.html#sec:G64.

>> the corner can become very asymmetric (see the demo at the end).

>> 8. Next we need to make sure, the blending still respects the

>> angles of 90°, nothing is adding up either way.

>> /deceleration/ ramp time and the second segment /acceleration/

>> should still always be respected (assuming we allow for the

>> deceleration is compensated by same acceleration, i.e. where the

>> get exactly what we want: no deceleration in near-straight junctions.

>> sure we always only blend /two/ segments together. It cannot reach

>> beyond.

>> 11. For acute angles, it is more complicated: Deceleration (which is

>> direction, get the same sign, i.e. they add up. The axis

>> acceleration limit could be violated, i.e. the allowable blending

>> time would be zero.

>> limit. The most challenged axis would then give the allowable

>> maximum deceleration/acceleration for the segments.

>> 14. Unfortunately similar to (9), the ramp times can be different in

>> the two segments. So the /optimal/ planner would have to plan with

>> /two/ deceleration or acceleration ramp phases, one that is

>> constrained by overlap and one that is not. /I guess that would

>> 15. The above steps were explained in a logical order. But in reality,

>> through (14) would have to precede step (2).

>> assume its makes sure the ramp of (at least) one co-linear segment

>> becomes one-sided. Because there is no ramp time, (9) and (13)

>> velocity that is non-zero. By excluding those, we only have to

>> deal with segments that decelerate/accelerate to/from still-stand,

>> so what was said in (9) still holds true. Furthermore, this

>> is no generalization, i.e. no valid replacement for that

>> optimization (as I was hoping for some time).

>>

>> See the animation (click to open):

>>

>> https://makr.zone/motion_blending_animation.html

>>

>> It has a higher acceleration on the second segment to demonstrate that

>> G64 calculation is not trivial (5). But note that the demo simply has

>> the same overlap time for all the examples, i.e. there is no "real

>> G64" applied.

>>

>> _Mark

>>

> You received this message because you are subscribed to the Google

> Groups "OpenPnP" group.

> To unsubscribe from this group and stop receiving emails from it, send

> an email to openpnp+u...@googlegroups.com

> <https://groups.google.com/d/msgid/openpnp/92661bcc-0b20-bcbb-3870-b3eea60597c3%40makr.zone?utm_medium=email&utm_source=footer>.

Ravi Ganesh

Hi Mark,

mark maker

"Currently, there is no function to set the maximum deviation

allowable in CANON_CONTINUOUS mode."

That section of the report does not describe G-code per se, but a possible "canonical" implementation of a controller. It is based on code they apparently wrote (not very clear, see 4.1.2.). IMHO that sentence is just describing shortcoming of their implementation at the time of the report. It does not mean there must not be such a function.

I think we should lean on LinuxCNC here:

http://www.linuxcnc.org/docs/2.6/html/gcode/gcode.html#sec:G64

_Mark