Feeders

thatlittlefrog

bert shivaan

What's a good feeder type for openPNP? I'm considering making clones of the lumenPNP photon feeders, Yamaha pneumatic CL feeders, or these https://www.deltaprintr.com/product/rapid-feeder/ rapid feeders, whenever they come out. I'm also considering creating my own custom feeder with closed loop tape control using the same sort of optical flow sensor found in computer mice. If that ends up being the case, are there any motors better than those somewhat expensive N20 gearmotors? I'm considering using FOC brushless motors for their high torque and speed, but that might be overkill for a simple feeder. I would like to be able to place 0201 and maybe 01005 components reliably.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion visit https://groups.google.com/d/msgid/openpnp/0f475886-368a-47f6-a200-0cc3afe75255n%40googlegroups.com.

Jarosław Karwik

Marco Blancato

Starting from Bing Luo’s MicroSMT project and the components I bought from him for just a few dollars, I decided to redesign the feeder in my own way, introducing some optimizations. But I have to say I’m experiencing poor positioning repeatability (while this issue doesn’t seem to exist in Bing’s original design). Sometimes happens an 0805 is misaligned by half its body, or a 0603 ends up completely out of place. I haven’t been able to identify the exact cause, but in any case, this problem is fully resolved by using the BambooFeeder in OpenPnP, which recognizes the tape holes.

Another critical point is the lightness of the feeder and the structure of a DIY machine itself, which makes it easier for small bumps or vibrations to cause components to pop out of the tape — especially with plastic tapes, which are thin and very elastic. I believe this issue is common to all feeders that don’t have a shutter to keep the components protected until just before pick-up.

I also purchased a couple of those T-2 feeders to see how they perform. Sixty dollars for a 3-slot 8mm feeder is quite an interesting price, considering that printing all the parts and assembling DIY feeders like mine or the MicroSMT one at home is a time-consuming and demanding task.

bing l

Mike Menci

Almost all feeders have spring under the slider under the tape to keep the tape at the same hight regardless of tape thickness...

Marco Blancato

Thanks for the suggestion, it's something I hadn't thought of. That's why I use different tape covers depending on the type of tape, so that the tape has no play. Of course, a spring-loaded mechanism would be more practical and functional, and I'll definitely keep it in mind for a future redesign. I can't clearly see from the photo how you implemented it—do you have a more detailed picture?

thatlittlefrog

bing l

thatlittlefrog

thatlittlefrog

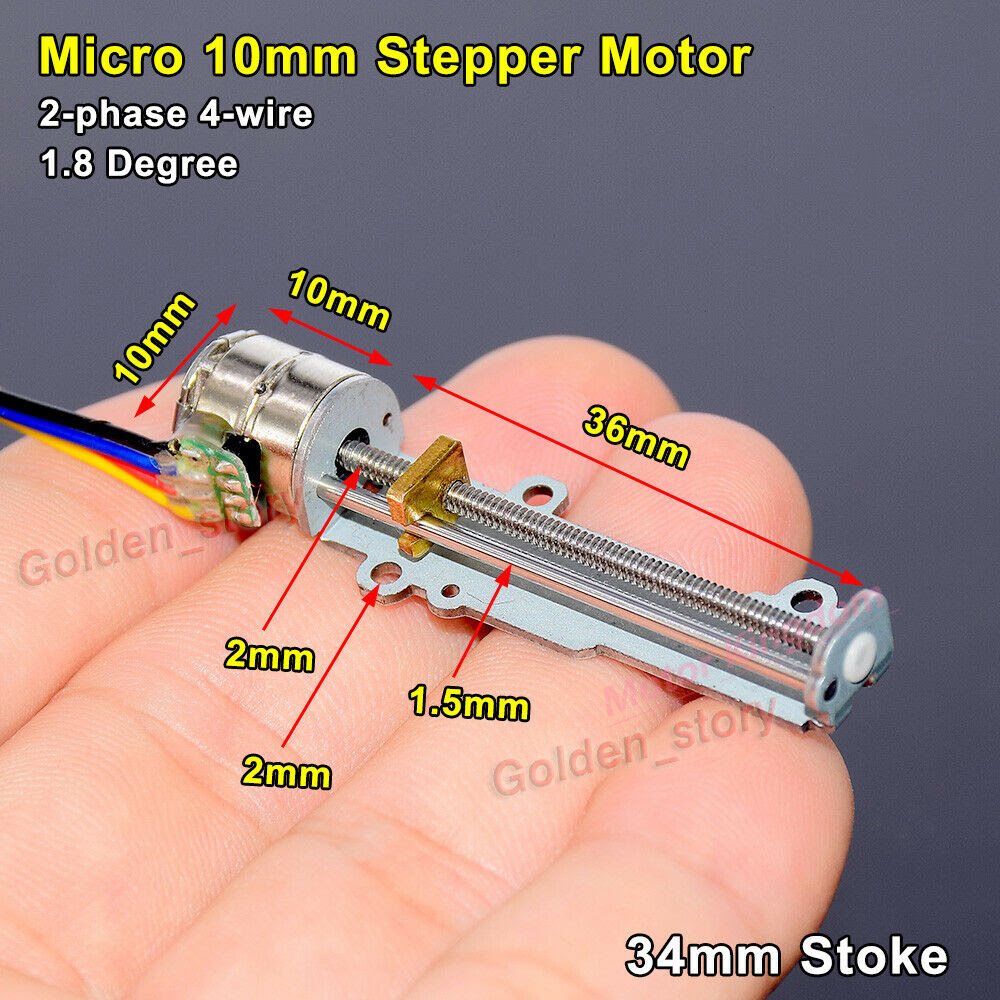

Cheap - These steppers can be found for a dollar or two on Aliexpress

serge a

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion visit https://groups.google.com/d/msgid/openpnp/8550e48c-e9d8-485b-be51-2a153421e2f7n%40googlegroups.com.

bing l

Jonathan Crossley

.jpg?part=0.1&view=1)

Mike Menci

thatlittlefrog

Tony Huynh

Jim Drew

Marco Blancato

I’ve printed and built around 20 feeders, but they all have major issues with the precise positioning of the component when the tape advances — and that causes a lot of frustration.

With cardboard tapes and components down to 0805, the errors are manageable and tolerable. But with plastic tapes or 0603s (let alone 0402s), it’s a nightmare.

So at the moment, I only use these feeders for 0805 resistors (with some cursing), and I handle everything else with simple StripFeeders or even manually.