API 582

168 views

Skip to first unread message

K K

Jun 29, 2020, 10:51:43 AM6/29/20

to Materials & Welding

Dear Experts.

Can anyone suggest to according to API 582 as per TABLE - A1 has not recommended ER80S-Ni1 for AWS 5.28 GTAW process.

Please explain to me in detail the table - A1 API 582 and which electrode shall I use for the below-mentioned material.

PQR material - ASTM A333 Gr.6 to ASTM A350 LF2.

PQR Thickness - 12.7 mm.

Impact tested - -46°C

Thanks and regards,

Kiran

Nithin Joseph

Jun 29, 2020, 11:40:52 PM6/29/20

to material...@googlegroups.com

ASTM A333 Gr.6 to ASTM A350 LF2.

Both materials are 70 KSI grades, hence matching filler wire is ER 70S types. You can decide on designation after verifying with MTC, preferably ER 70S-3 or 6.

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/dbf583fe-f42a-4eb3-9975-5c62126d6ef2o%40googlegroups.com.

Karthik

Jun 29, 2020, 11:41:14 PM6/29/20

to Materials & Welding

Hi,

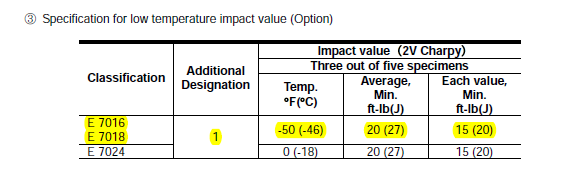

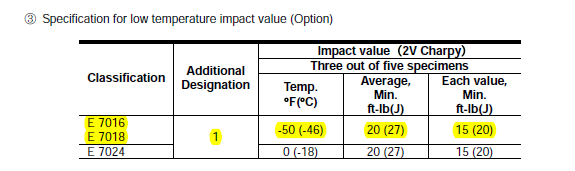

You can use E7018-1 / ER70S-1B / ER70S-6

--

Vanchinath S.A.

Jun 30, 2020, 5:09:57 AM6/30/20

to material...@googlegroups.com

ER 70S2 spl wire is available meeting nace requirements and impact at minus 46 Deg C

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAFS9gDNufywHY_mOW_nedvPWyoZZ2X6iUZLQkmLVmfCxL%2B3e_g%40mail.gmail.com.

K K

Jun 30, 2020, 5:09:57 AM6/30/20

to Materials & Welding

Thanks for your response.

Please explain to me why I can't use ER80S-Ni1 for AWS 5.28 GTAW process according to the table - A1 API 582.

Thanks

Kiran

On Tuesday, June 30, 2020 at 9:11:14 AM UTC+5:30, Karthik wrote:

Hi,You can use E7018-1 / ER70S-1B / ER70S-6

Dear Experts.--Can anyone suggest to according to API 582 as per TABLE - A1 has not recommended ER80S-Ni1 for AWS 5.28 GTAW process.Please explain to me in detail the table - A1 API 582 and which electrode shall I use for the below-mentioned material.PQR material - ASTM A333 Gr.6 to ASTM A350 LF2.PQR Thickness - 12.7 mm.Impact tested - -46°CThanks and regards,Kiran

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to material...@googlegroups.com.

Karthik

Jun 30, 2020, 6:47:41 AM6/30/20

to Materials & Welding

Hi,

Since this is P.No.1,Low temperature material, why do you go for ER80S-Ni1 ? Its used for weathering steel and corrosion resistant applications. It can be used to weld SA350, LF5 (P.No.9A) which is 1.5Ni steel

SA350, LF2 and SA333 Gr.6 are C-Mn-Si steel (P.No.1), for this ER70S2 or ER70S-6 are fine. Electrode E7018-1

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit

manish kulkarni

Jun 30, 2020, 11:12:18 PM6/30/20

to material...@googlegroups.com

ER 70 S2 and E 7018-1 do not give consistent impact at -46 Deg C . Many failures are reported.

For guaranteed impact at -46 deg C ER 80SNi 1 Can be used Sometimes there are restrictions in some services due to preferential weld corrosion problem.

Regards

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CA%2B6Tn1%2B5STmLuG%2BJ%3DN6%2Bn3v0Qhjzscd9xrV_-Wpd-MDpEoHoMw%40mail.gmail.com.

GENE MATSKO

Jul 2, 2020, 12:05:41 AM7/2/20

to 'manish kulkarni' via Materials & Welding

E-7018-1 will give consistant impact properties if the test coupon is welded correctly. One must restrict any weaving and

maintain a fairly high travel speed to insure optimum impact results @ -46C

Gene Matsko

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1630776032.479934.1593537768950%40mail.yahoo.com.

GENE MATSKO

Jul 2, 2020, 12:05:44 AM7/2/20

to 'manish kulkarni' via Materials & Welding

The test must be 'monitored' to insure optimum results. You must assure the welder follows the welding instructions

exactly. 1. No weaving. 2. High travel speed. 3. Let the coupon cool between layers.

Gene Matsko

On Tuesday, June 30, 2020, 10:12:16 PM CDT, 'manish kulkarni' via Materials & Welding <material...@googlegroups.com> wrote:

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1630776032.479934.1593537768950%40mail.yahoo.com.

Vishwas Keskar Welding Manager WELDING

Jul 13, 2020, 2:30:53 AM7/13/20

to Materials & Welding

ER70S-6 - will give you required values .

ER80S-Ni1 is not advised in certain environments especially Sulphur or H2S due to corrosion in presence of Ni, S, H2

Reply all

Reply to author

Forward

0 new messages