PQR mentioning position 3G and our WPS stated 1G

Zulfan

muthu barathi

hi

by using existing pqr u can prepare wps when the material is same, not nececessary to make a fresh pqr

On Thu, 11 Nov 2010 20:16:59 +0530 wrote

>

To post to this group, send email to material...@googlegroups.com

>

To unsubscribe from this group, send email to materials-weld...@googlegroups.com

>

For more options, visit this group's bolg at http://materials-welding.blogspot.com/

>

The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

>

Dear Sir,

Thanking You,

Honesty is the best Policy

With Warm Regards,

Muthu Barathi P

Mobile No:00962788269821 (Jordan)

00962775401951

siva chidambaram

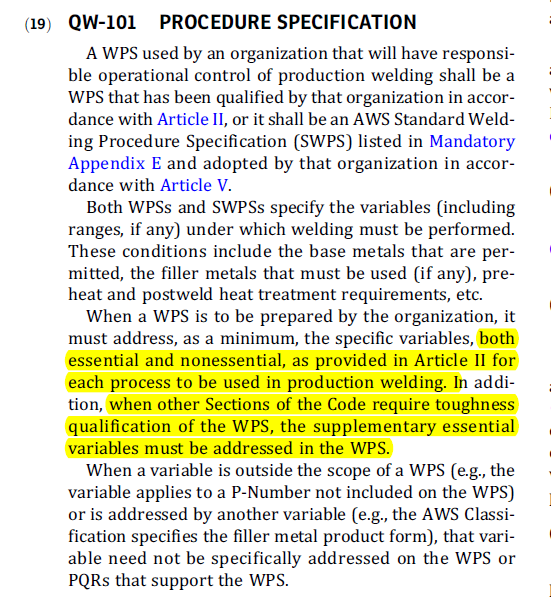

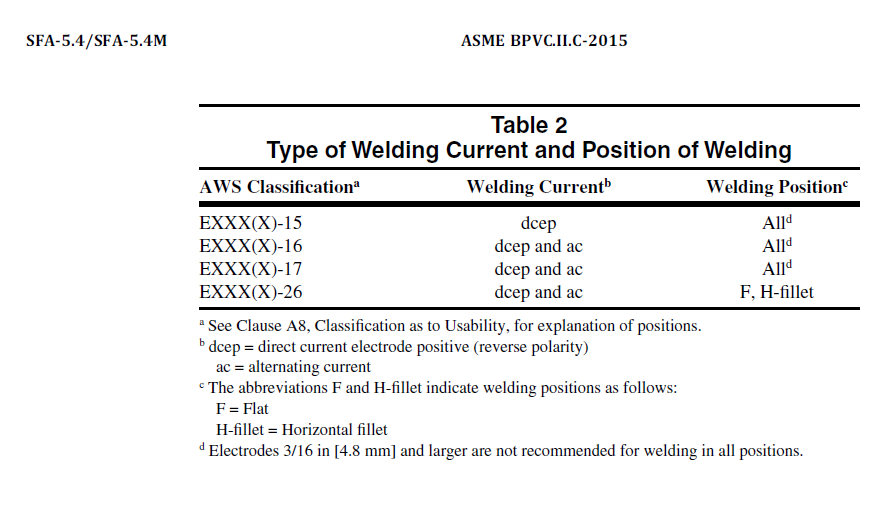

As per ASME sec. IX, The addition of position is a non essential variable, also change in position is supplementary variable. If your PQR doesn't have impact test, you may use the same WPS, You need not to go for a new PQR.

Hope you understand the summary.

M.Sivachidambaram

+919597165173

--

pavainathan

Position of welding is not a Essential variable for Procedure

qualification ie you can use the WPS for any position .in case of

welders qualification it is essential variable.

Your WPS can be used for 1G with the PQR qualified in 3G.

In general practice the welder who welds PQR test piece is also

qualified hence we are qualifying in 6G position to enable welder

qualification in parallel with PQR

regards,

vaithiyanathan

Fernando Alvarez

--

israr

You just delete position 1 g from wps and write All,

As per ASME Section IX if WPS is qualified in any one position of 1G

to 6G it is qualify for all the position.

Then u can attached nos of PQR with dirrent position following the

same WPS.

Regards

Israr Ahmed

Tata Projects Ltd.India

+919930308261

Mohammed Zakeruddin

george....@gr.bureauveritas.com

If your Code is ASME and if your project specifications do not include any additional requirements, then you may proceed as follows:

Position is not an essential variable for WPS qualification, so you do not need a new PQR.

You draft a new WPS based on the essential variables of the existing PQR and you include also the position 6G.

Then you can qualify the welder

- best regards

Dr. Georgios Dilintas

Authorized Nuclear Inspector

Authorized Inspector Supervisor

I&F REGIONAL TECHNICAL MANAGER

BUREAU VERITAS HELLAS

Tel: +30 210 40 63 113/4

Fax: +30 210 40 63 118

Cell: +30 69 44 64 62 04

(See attached file: Dilintas_George.vcf)

--

To post to this group, send email to material...@googlegroups.com

To unsubscribe from this group, send email to materials-weld...@googlegroups.com

For more options, visit this group's bolg at http://materials-welding.blogspot.com/

The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

This message contains confidential information. To know more, please click on the following link: http://disclaimer.bureauveritas.com

Rash

If your Code is ASME and if your project specifications do not include any additional requirements, then you may proceed as follows:

Position is not an essential variable for WPS qualification, so you do not need a new PQR.

You draft a new WPS based on the essential variables of the existing PQR and you include also the position 6G.

Then you can qualify the welder

best regards

Dr. Georgios Dilintas

Authorized Nuclear Inspector

Authorized Inspector Supervisor

I&F REGIONAL TECHNICAL MANAGER

BUREAU VERITAS HELLAS

Tel: +30 210 40 63 113/4

Fax: +30 210 40 63 118

Cell: +30 69 44 64 62 04

(See attached file: Dilintas_George.vcf)Mohammed Zakeruddin ---20/10/2014 08:40:47---Dear All, Kindly advise,

To unsubscribe from this group, send email to material...@googlegroups.com

For more options, visit this group's bolg at

The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

james gerald

Thanks & Regards

J.Gerald Jayakumar

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/aeef7d9d-e9b6-40ec-9f0b-d98e790ee499%40googlegroups.com.

Kannayeram Gnanapandithan

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

This message contains confidential information. To know more, please click on the following link: http://disclaimer.bureauveritas.com

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

harenath jha

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

This message contains confidential information. To know more, please click on the following link: http://disclaimer.bureauveritas.com

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

Karthik

mohammed rafi

Charles Jacob

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1609987039.1609743.1582962937925%40mail.yahoo.com.

José Juan Jiménez Alejandro

If we are working with ASME IX, I think that from the beginning there was ignorance of the Code, if your PQR mentions 3G, your WPS would have written it (if that wording was on your own) to fulfill all the positions, for example 6G If you are using it for pipes, at that time you could rate your welders in the position that the needs of your project require.

Remember, there are essential variables for the PQR and WPS and others for welders, but I suggest you review and study the Code carefully and do not wait for your questions to be resolved in a forum.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAKpzM4BGo9hzW_zdNsMUxjMOA%2B%3D%3DwzcbWmHYDwHYBHfwnqmLLQ%40mail.gmail.com.

Ing. José Juan Jiménez Alejandro

Independent Consultant in Parts

and Pressure Equipment

SSI-TPI

Móvil +52 1 812 352 4606

Skype: jjjimeneza

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAO5Zur%2Bt_1fqhHZ9B9DYQjzUR%3DBJPVo_OfYeNJK8Pne2az8%3D9Q%40mail.gmail.com.

james gerald

Thanks & Regards

J.Gerald Jayakumar

james gerald

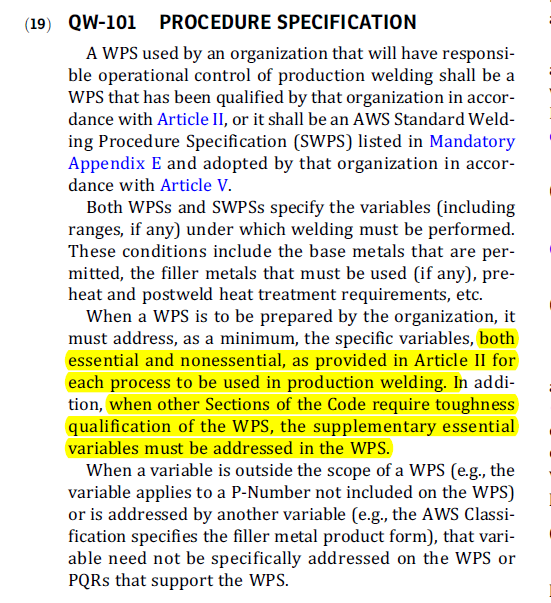

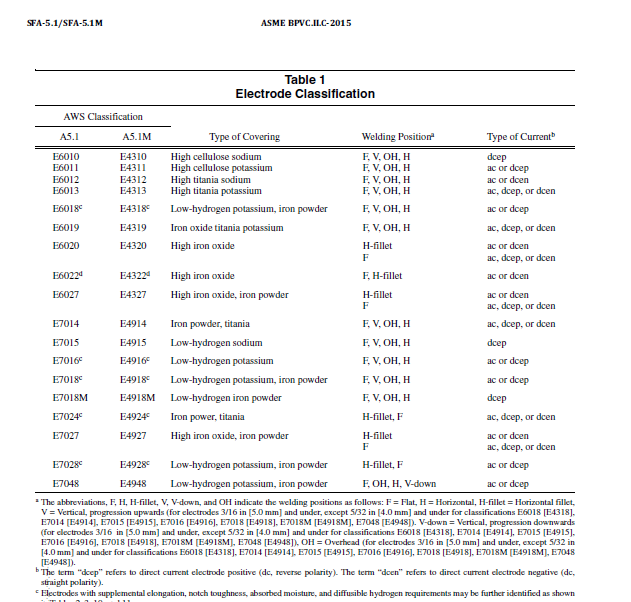

-26 is restricted by most specifications as alloying additions through Flux coating using a mild steel core wire

Thanks & Regards

J.Gerald Jayakumar