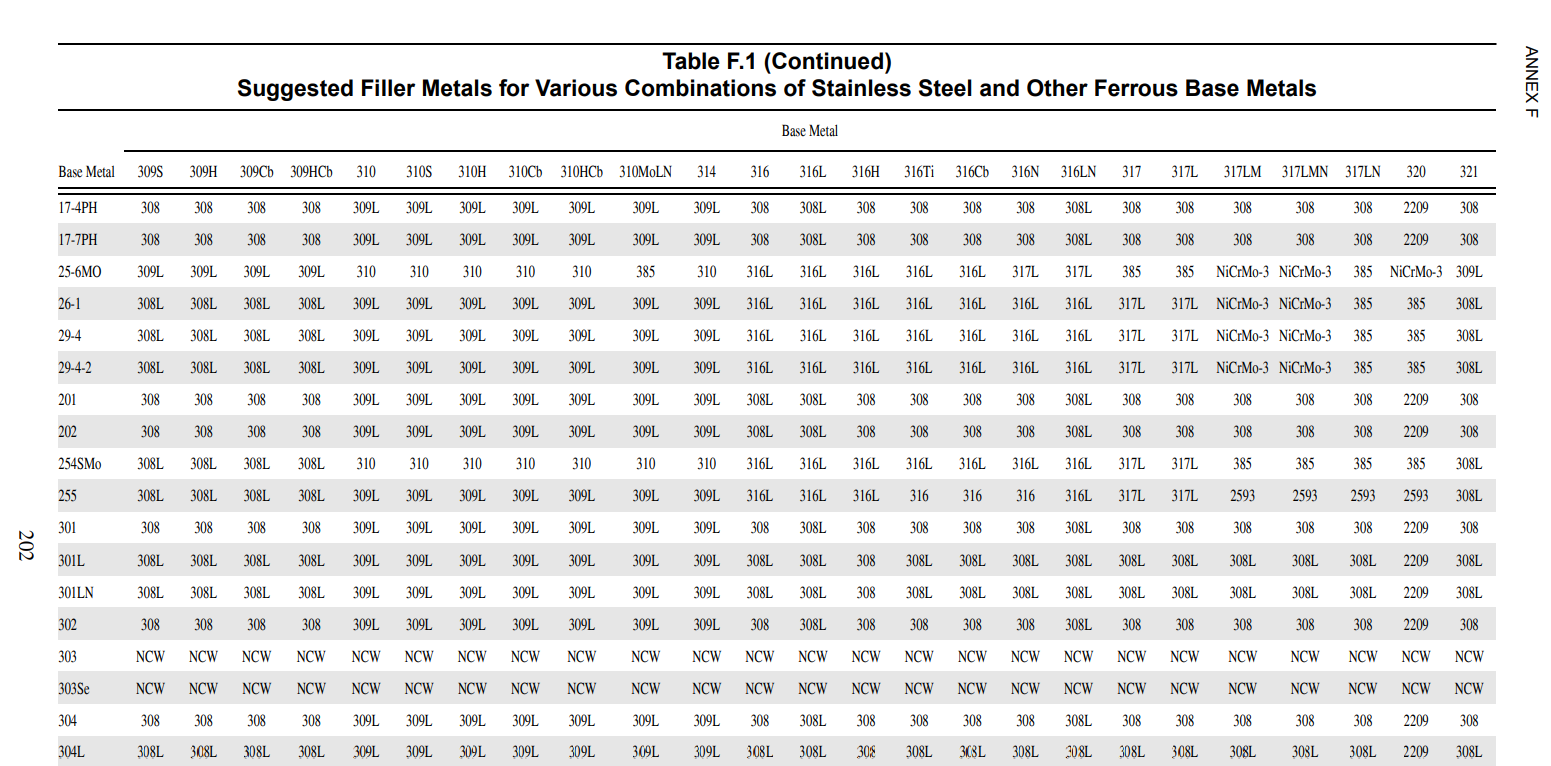

filler material between 304L and 316L

Chiranjeevi A

james gerald

Thanks & Regards

J.Gerald Jayakumar

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAN4%2Bm0xA0VB5ScFArEbYRJMODF7D%2B0dwsfdrL4qO1GygpVXhzg%40mail.gmail.com.

Vinay Thattey

--

Ramon Briceno

Dear Chiranjeevi for this 304L / 316L weld, a qualified WPS should have been used where the filler material was superior metallurgy for the joint. In this case, use type 316L filler material to achieve adequate Mo content as protection against intergranular corrosion by chlorides, for example.

Sorry, I think you're going to have to cut those 20 welds made with 308L.

In all Codes and Standards, good welding practices indicate the correct combination.

Regards,

Ramon Briceno

Metallurgical Engineer.

Amon

Sent from Mail for Windows 10

--

Arun Padman

Plant Inspector

Tel:+974 50577156

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/MN2PR06MB65254D6C3DF9A098E4303654AA569%40MN2PR06MB6525.namprd06.prod.outlook.com.

Ramon Briceno

Dear Arun,

From the Recommended Practice API 577: "Welding Processes, Inspection, and Metallurgy", it is achieved:

Annex D, Table D.2 reads: —Common Welding Consumables for SMAW of Carbon and Low-allow Steel.

It should say: —Common Welding Consumables for SMAW of Stainless Steel.

This table contains the Base Metal combination for stainless steels.

If we observe, it has three calls: 1, 2, 3.

Call 2, says: "The higher alloy electrode specified in the table is normally preferred".

This confirms that if you have two different Base metals (304L and 316L, for example) within the same SS family, the electrode that is chosen is the one that contains more alloying elements compatible with the higher alloyed base metal. In this case, the welding electrode for the combination 304L / 316L should be E-316L. (AWS A5.4 Classification E316L-XX).

It is understood that the weldability in this combination is maintained, regardless of whether you use E-308L or E-316L.

The service, the current of the fluid that is handled, would be the determining factor to use one or the other.

Regards,

Ramon Briceno

Metallurgical Engineer.

Sent from Mail for Windows 10

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAHbaPvJ9208Wi3mZK2KCS1UyttfJTzrtwN8kFU%3DNzE49XoC1Cg%40mail.gmail.com.

Vanchinath S.A.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAHbaPvJ9208Wi3mZK2KCS1UyttfJTzrtwN8kFU%3DNzE49XoC1Cg%40mail.gmail.com.

Xuân Thông

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAHbaPvJ9208Wi3mZK2KCS1UyttfJTzrtwN8kFU%3DNzE49XoC1Cg%40mail.gmail.com.

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CA%2B6Tn1K75m%3DQy1orSDLA_818T2pkmzKQ_%2BG9FRQ%2Br%3DHHg7h7tw%40mail.gmail.com.

Mani

P Number & Group Number are same for 304L & 316L.( P8 & Gr-1)

For the consumables , it has the same F Number & A Number. ( F-6 & A-8)

So it is acceptable...

Mani

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4eOLP%2BZzL7JmMr%3DvxJt6Z5%3Dqj9DisGRFHM77GKu1%3DomCHw%40mail.gmail.com.

Ganesh Muthurajan

--

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAM0EmFK7dEtO_L2r%2B%2BKU9kFCJCpB3CNidq_dUgtSKoXUP1nOpw%40mail.gmail.com.

Ron Mays

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4eOP8vfLatT%2BVZ9ChS7ri79L%3DCSGEdoutYgLu6%3DGMr3Rjg%40mail.gmail.com.

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CALXgsa1hD%2BNFc0z9Md_wi%3Dty2X7LArwk_gSDHO8rM8ycjJcpJw%40mail.gmail.com.

Chiranjeevi A

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4ePmrbw2p1mY3YUmw%3Dhbf4-LPvUfPHMpzv8XoZ6-Dn4fKw%40mail.gmail.com.