Can i weld A36 or equivalent S275JR with E7018-B2L?

46 views

Skip to first unread message

chris

Apr 12, 2020, 11:46:46 PM4/12/20

to Materials & Welding

our customer specifies ultra low carbon content with elevated nickel. Is there any other welding that i can use in this case?

james gerald

Apr 13, 2020, 12:56:40 AM4/13/20

to material...@googlegroups.com

What is your MDMT (minimum Design Metal temperature) at which Impact test to be conducted.

Try E 7018-C3L as it provides Impact test upto to -50degC and also contains Nickel.

E 7018-B2L is a chromium Molybdenum electrode which do not contain much Nickel

Thanks & Regards

J.Gerald Jayakumar

our customer specifies ultra low carbon content with elevated nickel. Is there any other welding that i can use in this case?

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/f52cfb16-c52a-436a-a0af-7437a3aa51c8%40googlegroups.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/f52cfb16-c52a-436a-a0af-7437a3aa51c8%40googlegroups.com.

Chris Sabu

Apr 13, 2020, 8:17:52 AM4/13/20

to material...@googlegroups.com

hi james,

They really don't have any impact test requirement which is weird though. They require carbon content less than .04% and elevated nickel content.

I don't see any variation with both these parameters.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/361481876.3065893.1586752043677%40mail.yahoo.com.

THANKS AND REGARDS

CHRIS SABU

0559695451

George Dilintas

Apr 13, 2020, 8:17:55 AM4/13/20

to material...@googlegroups.com

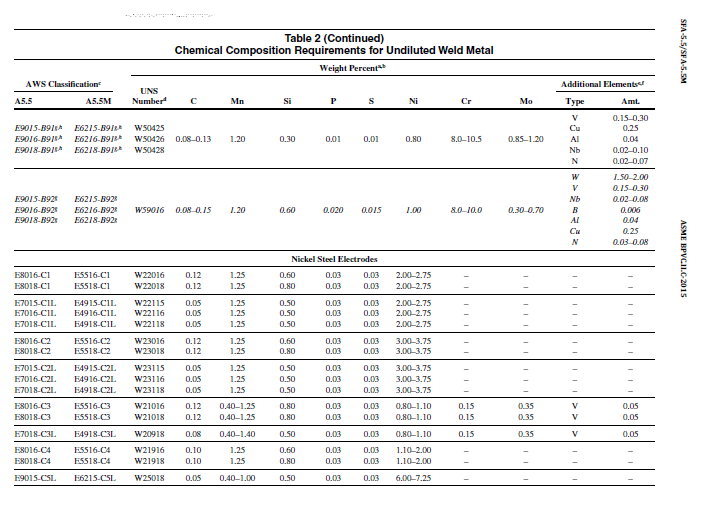

You should look on SFA-5.5

Στις Δευ, 13 Απρ 2020 στις 6:46 π.μ., ο/η chris <chris...@gmail.com> έγραψε:

our customer specifies ultra low carbon content with elevated nickel. Is there any other welding that i can use in this case?

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/f52cfb16-c52a-436a-a0af-7437a3aa51c8%40googlegroups.com.

Dr. Georgios Dilintas,

Dipl. Ing. In Aeronautic and Space Engineering

Ph.D in Mechanics of Solids - Computational Mechanics

A.I.S, A.N.I, IRCA Lead Auditor

Welding, Stress Analysis, Corrosion, QA/QC, Failure Analysis, Risk Analysis

james gerald

Apr 14, 2020, 12:08:50 AM4/14/20

to material...@googlegroups.com

From the Material ASTM A36 and 275JR I understand they are not LTCS material.

try E 7018C2L or E 7018C1L with the maximum carbon of 0.05% and welding consumable MTC will show lower amounts.

Thanks & Regards

J.Gerald Jayakumar

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CACY3QXTPfXh6y0uyBh81X-YodFeDpSnG3xTf9T0SY4ALvmxFdQ%40mail.gmail.com.

Kannayeram Gnanapandithan

Apr 14, 2020, 1:08:46 AM4/14/20

to materials-welding

7018-1 itself will work for-43°C

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1247802736.3267726.1586791298688%40mail.yahoo.com.

Chris Sabu

Apr 14, 2020, 3:36:21 AM4/14/20

to material...@googlegroups.com

Thanks James ,

I think I can work something out with this

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1247802736.3267726.1586791298688%40mail.yahoo.com.

Reply all

Reply to author

Forward

0 new messages