HAZ size

35 views

Skip to first unread message

Hany Nabil

Dec 6, 2020, 9:02:49 AM12/6/20

to material...@googlegroups.com

Dear exports,

For HAZ in side welding depending on heat input.

How to calculate HAZ distance ?

Any equation formula ?

Thanks,

-- Best Regards,

Eng. Hany Nabil

Senior Welding Engineer

Petrofac

Engineering and Production Service

Email: eng.han...@gmail.com

Egypt Mobile: 002-01225622022

This message, including any attachments, may contain confidential and privileged information for the sole use of the intended recipient(s). Review, use, distribution or disclosure by others is strictly prohibited. If you are not the intended recipient, or authorised to receive information on behalf of the recipient, please contact the sender by reply email, and delete all copies of this message. While we have taken reasonable precautions to ensure that this message and any attachments are free from viruses, we cannot guarantee that they are virus free and accept no liability for any damage caused by this message or any attachments. Messages sent or received through our networks may be monitored to ensure compliance with the law, regulation and/or our policies.

Patel Ankit

Dec 6, 2020, 10:26:25 PM12/6/20

to material...@googlegroups.com

Dear Sir,

Really Heat affected zone is measured regarding the micro-structure changes in the weld and also according to the experts. The theoretically calculation of HAZ may be not accurate to depend.

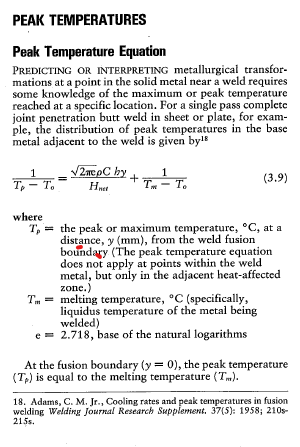

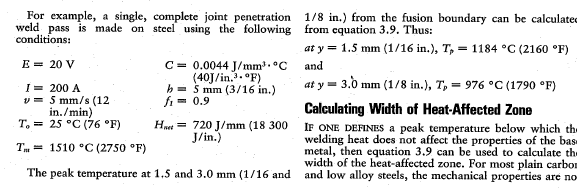

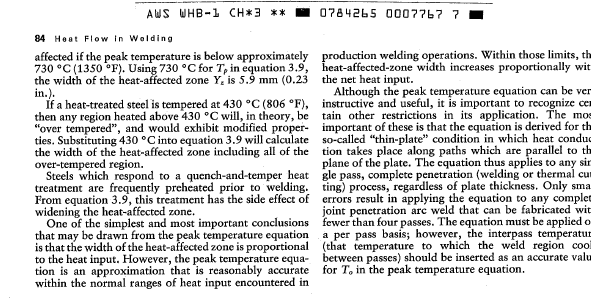

You can find such formula in chapter three of AWS Welding Handbook {Heat Flow in Welding}

1/Tp-To = 4.13pchY/ Hnet + 1/Tm-To;

where,

Y is width of HAZ in mm

h: plate thickness in mm

Tp is peak temperature,

To is initial plate temp (room temp or preheat temp),

pc-volumetric specific heat (J/mm3.C),

Tm is melting temp;

Hnet: net heat input (J/mm)

Regards,

Ankit Patel

Mo No : +91 8140255303

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAP1YJmQSgbkHQ0wm56Errx%3Dab4xHVeHwh35oOGEVMeBpDPLhrA%40mail.gmail.com.

George Dilintas

Dec 7, 2020, 3:02:21 AM12/7/20

to material...@googlegroups.com

I have done this using FE simulation

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAP1YJmQSgbkHQ0wm56Errx%3Dab4xHVeHwh35oOGEVMeBpDPLhrA%40mail.gmail.com.

Dr. Georgios Dilintas,

Dipl. Ing. In Aeronautic and Space Engineering

Ph.D in Mechanics of Solids - Computational Mechanics

A.I.S, A.N.I, IRCA Lead Auditor

Welding, Stress Analysis, Corrosion, QA/QC, Failure Analysis, Risk Analysis

james gerald

Dec 7, 2020, 3:22:47 AM12/7/20

to material...@googlegroups.com

Taken from AWS Handbook Volume 1, Chapter3, Heat Flow in Welding

Thanks & Regards

J.Gerald Jayakumar

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAPOi40BD79nzA72ncN5%3DjfmRa06aX3pb0DR%3D%2BsFKqkdtYUccWg%40mail.gmail.com.

Reply all

Reply to author

Forward

0 new messages