3 Cycle PWHT requirements acc.to ASME

K K

Peter Soloman

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/2b255cdf-b673-4981-8fcf-ad1fb4863ecbo%40googlegroups.com.

K K

On Tuesday, June 23, 2020 at 11:43:19 AM UTC+5:30, petervsoloman wrote:

Dear Kiran,Once PWHT competed for joints due to modification cut/reweld or repair re PWHT required that particular joints.it is mention in the procedure is enough to do the job. This you can mention in your weld repair procedure.Regards,PETER SOLOMAN

On Mon, Jun 22, 2020 at 7:32 AM K K <kara...@gmail.com> wrote:

--Dear All,Please describe to me regarding 3 cycle PWHT requirements as per ASME.If my PQR tested with two coupons where I required one more test coupon and additional one more for repair.Please explain to me in detail and related to mechanical testing for PWHT.What is the meaning of this paragraph - **an additional one PWHT cycle shall be incorporated to simulate field repair or modification.**Thanks and RegardsKiran

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to material...@googlegroups.com.

K K

MW

K K

james gerald

Thanks & Regards

J.Gerald Jayakumar

To view this discussion on the web visit

Kiran Ekbote

Heat Treatment required for the Weld.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1700708950.2832782.1593157682597%40mail.yahoo.com.

KIRAN

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1700708950.2832782.1593157682597%40mail.yahoo.com.

james gerald

Thanks & Regards

J.Gerald Jayakumar

José Juan Jiménez Alejandro

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/299870276.3117366.1593218167469%40mail.yahoo.com.

Ing. José Juan Jiménez Alejandro

Independent Consultant in Parts

and Pressure Equipment

SSI-TPI

Móvil +52 1 812 352 4606

Skype: jjjimeneza

HENNING John

There is no requirement within ASME Section I or Section VIII to perform a simulated PWHT for three cycles. This a common requirement in petro-chemical specifications and, occasionally, other customer specifications.

See Section VIII, Division 1, UCS-85, “Heat Treatment of Test Specimens” for base metal simulated heat treatment requirements. This is typically a single cycle mimicking the production heat treatment.

There is no comparable requirement in ASME Section I.

Hope this helps. Code is fun.

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to

materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAO5Zur%2B3wN6%3Dab77bXffxpPis%2BoAWpbG46RuT-SoaKkm82zo6g%40mail.gmail.com.

General Data Protection Regulation (GDPR)

We respect and protect your privacy to provide you with our services. Please read https://www.hamon.com/customer-data-protection-notice (Customer) and https://www.hamon.com/seller-data-protection-notice (Supplier) how we process your personal data.

Thank you for your cooperation.

______________________________________________________________________

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/AM7PR01MB7076209D20F4C4B209C2B98A90900%40AM7PR01MB7076.eurprd01.prod.exchangelabs.com.

ishwar kumar

Dear Kiran

This requirement in ASME/AWS D1.1 is a supplementary essential variable and required when the construction code requires the component to be impact tested.

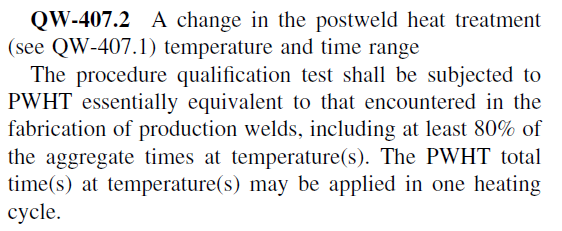

Generally we have the PQR PWHT time at temperature held long enough to cover 2 heat treat cycles of the thickest material to be welded. That way if we need to have a second heat treat cycle for any reason e.g weld repairs the welds are qualified. This is cheaper than having to re-qualify.

PQR must have the hold time so that it is at least 80% of the hold times used for production. If the production welding will need 2 hours of hold time the PQR must have 80% of 2 hours = .8 x 2 = 1.6 hours. The PQR must also be held at temperature for the construction code minimum based on weld thickness.

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/2b255cdf-b673-4981-8fcf-ad1fb4863ecbo%40googlegroups.com.

José Juan Jiménez Alejandro

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/24383D5A-AD0A-49A0-9FD8-58C12537A8D0%40gmail.com.

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAO5Zur%2BpU%2B2taf%2BRwZ6vrrjUupCjsKVTwSB2okzzFUznHFY5jg%40mail.gmail.com.

Karthik

K K

Sourav Bohrays

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4eM%2BSXVkShqVi-OoHUL1X87UQdJ%3DU1PpmBJwqUdHGd_e7Q%40mail.gmail.com.

Sourav Bohrays

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/3d9bfe80-783d-4fa4-b161-4e80cde66952o%40googlegroups.com.

Sourav Bohrays

--

Sourav Bohrays

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/299870276.3117366.1593218167469%40mail.yahoo.com.

Sourav Bohrays

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAO5Zur%2B3wN6%3Dab77bXffxpPis%2BoAWpbG46RuT-SoaKkm82zo6g%40mail.gmail.com.

Sourav Bohrays

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAMFjUk7zY2e8yd784D1i57j3WFLVoXxf_wHR4i1fPeTsWJLC5A%40mail.gmail.com.

K K

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to material...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1700708950.2832782.1593157682597%40mail.yahoo.com.

----

KIRAN

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to material...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAMFjUk7zY2e8yd784D1i57j3WFLVoXxf_wHR4i1fPeTsWJLC5A%40mail.gmail.com.