Hardness for vessel after PWHT

Kumar

Dear experts,

In our project for pressure vessels, moc- SA 516 gr.70 N, shell thickness 55mm (nace MR 0175). After doing PWHT, hardness measured and most of readings found in limit.

According to procedure vessels having more than 50mm thick hardness value shall not exceed more than 225 (brinell for p no. 1). But some values are 228,230,18 etc.. could we get expert advise to adress this dis-parity pl.

Thanks in advance,

Kumar.

pgoswami

Hi Kumar,

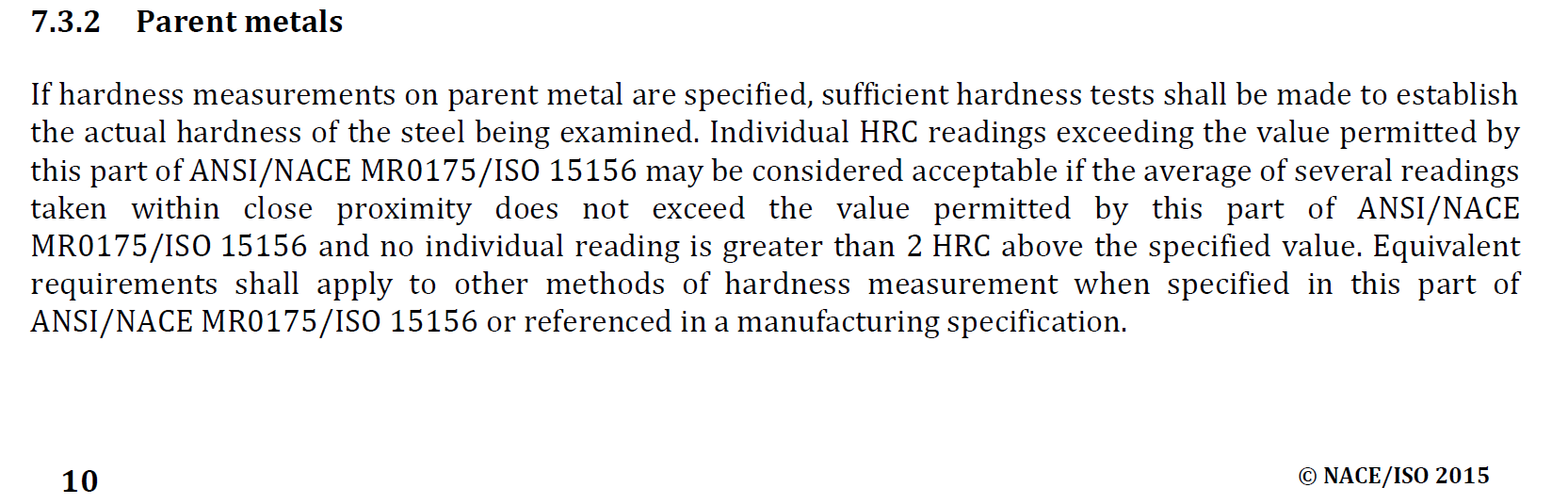

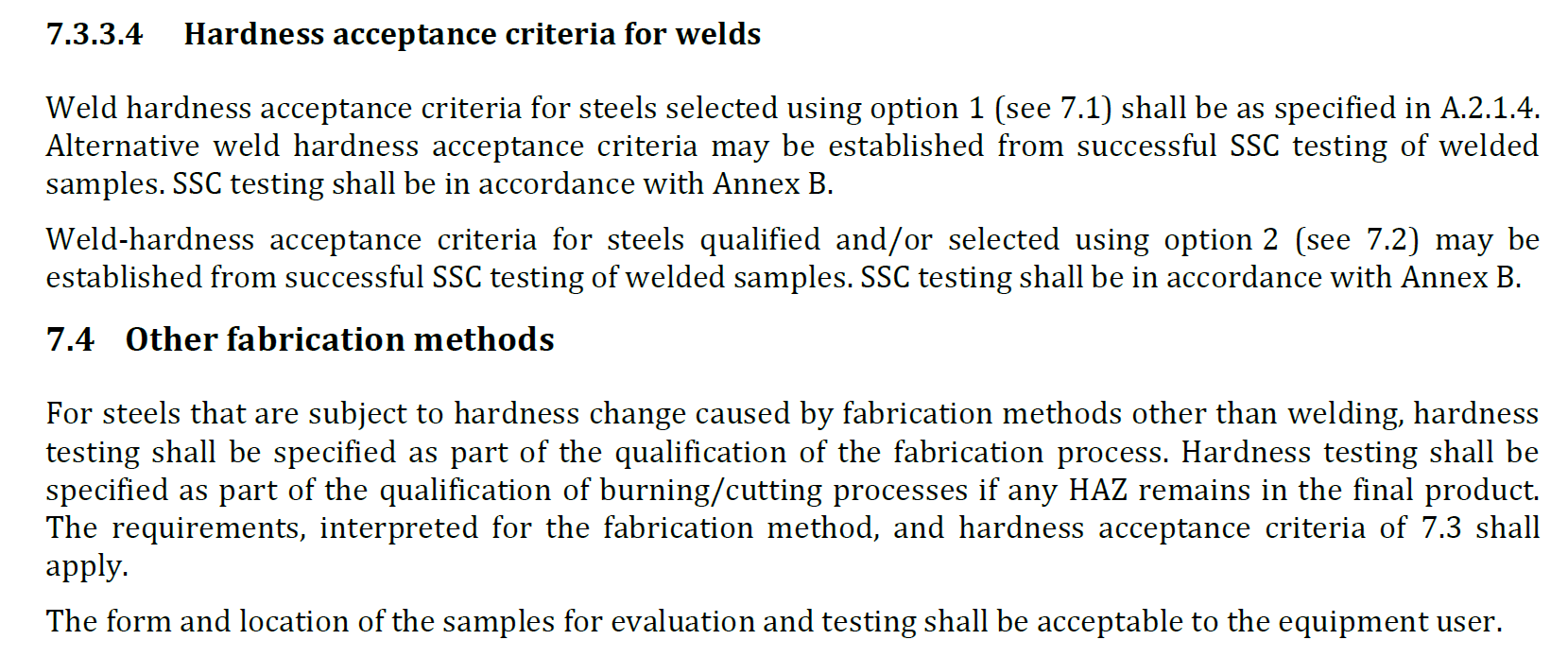

These readings are taken by portable hardness tester ?? Tele brinneler?? If these higher hardness reading are isolated, prepare the surface well to avoid any unevenness and retake the readings around the tested areas.

Isolated high readings may be ignored.

Hope this article would provide some guidance to this issue.

Thanks.

Pradip Goswami, P.Eng,IWE

Welding & Metallurgical Engineering Specialist ,

Ontario,Canada.

ca.linkedin.com/pub/pradip-goswami/5/985/299

--

http://www.linkedin.com/groups/MaterialsWelding-122787?home=&gid=122787&trk=anet_ug_hm

The views expressed/exchnaged in this group are members personel views and

meant for educational purposes only, Users must take their own decisions w.r.t.

applicable code/standard/contract documents.

---

You received this message because you are subscribed to the Google Groups

"Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email

to materials-weld...@googlegroups.com.

To post to this group, send email to material...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CALuBtp_S7ubrboSF%2BeMt6pDHCZasQOmpY4Lo7E_Y-VZzmfBumQ%40mail.gmail.com.

For more options, visit https://groups.google.com/d/optout.

Perumal Govindan

Hi

Please provide your hardness report for review to clarify.

Regards

Govindan

--

http://www.linkedin.com/groups/MaterialsWelding-122787?home=&gid=122787&trk=anet_ug_hm

The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To post to this group, send email to materials-welding@googlegroups.com.

Prakash Hegde

To post to this group, send email to material...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CANiuf9cf-kG_wLa5cwRSNMC_p4Ti6%3DK2S4wje_Psggr3iwHQpQ%40mail.gmail.com.

Perumal Govindan

--

http://www.linkedin.com/groups/MaterialsWelding-122787?home=&gid=122787&trk=anet_ug_hm

The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsubscribe@googlegroups.com.

To post to this group, send email to materials-welding@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CALuBtp_S7ubrboSF%2BeMt6pDHCZasQOmpY4Lo7E_Y-VZzmfBumQ%40mail.gmail.com.

Kumar

Many thanks for your valuable feed backs. Also regret for the late response.

Regarding the above, there was a mis-understanding that is in fact HAZ

& base metal hardness was restricted to 225 HB while weld metal was at

236 HB. since one party raised this assuming 225 HB is applicable for

all. Anyhow, all are within limit and hence OK.

The testing was done with portable machine (MIC 10).

I have one more query, when & where Brinell & vickers applicable specifically.

Thanks in advance,

Kumar.

>> To post to this group, send email to material...@googlegroups.com.

>> msgid/materials-welding/CALuBtp_S7ubrboSF%2BeMt6pDHCZasQOmpY4Lo7E_Y-

>> VZzmfBumQ%40mail.gmail.com

>> .

> http://www.linkedin.com/groups/MaterialsWelding-122787?home=&gid=122787&trk=anet_ug_hm

> The views expressed/exchnaged in this group are members personel views and

> meant for educational purposes only, Users must take their own decisions

> w.r.t. applicable code/standard/contract documents.

> ---

> You received this message because you are subscribed to the Google Groups

> "Materials & Welding" group.

> To unsubscribe from this group and stop receiving emails from it, send an

> To post to this group, send email to material...@googlegroups.com.