"Light Straw Color"

Yunsok Bang

rahul ugale

Dear all ,

Please comment.

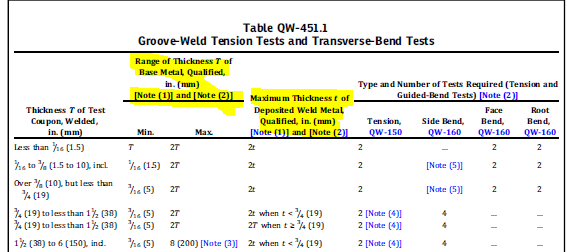

QW-403.6 The minimum base metal thickness qualified

For a WPS where impact test is applicable. As per QW-403.6 The minimum base metal thickness qualified is the thickness of the test coupon T or 16mm whichever less and if T less than 6mm, then 1/2T.

In the scenario, while filling the Weld Deposit range qualification in WPS, How we can enter the data. We can apply for the combination of both processes weld deposit thickness. But how to enter for individual process qualified range.

Ex: 1 ) Base Material Thickness – 53 mm GTAW (13mm),SMAW(20 mm) & SAW (20 mm) , So PQR Range is 16 mm – 200 mm, what will be the individual ranges for each process considering QW 403.6

Ex: 2 ) Base Material Thickness – 20 mm GTAW (8 mm) & SMAW (12 mm) So PQR Range is 16 mm – 40 mm, what will be the individual ranges for each process considering QW 403.6

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CACrdFNT7j1Ms005dt7WZNw-QNvcJFgohHpHkyhkk0NWvxNVVeA%40mail.gmail.com.

Jenish Mistry

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CALu9g8N8o%3DGxcuMv21P3YvS2tCRq7an%2BmSfcdK4Zg6oNEe%2BD3A%40mail.gmail.com.

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CALu9g8N8o%3DGxcuMv21P3YvS2tCRq7an%2BmSfcdK4Zg6oNEe%2BD3A%40mail.gmail.com.