PAUT Instead of RT

williams p wilson

Raghuram Bathula

anthony chundal

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAHBxnQ5hNvmec_a_qxOBGp66-DVsdUR7mT3WHOvS-%3DKX_dq4vg%40mail.gmail.com.

srinivas rao

you require to demostrate PAUT mock up prior to NDE test to your client and AI. no of blocks will differ based on your scope take opion of your LEVEL III.

williams p wilson

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/efb6a491-23fc-430b-93df-b43510f270e3n%40googlegroups.com.

srinivas rao

Regards,

srinivas rao

if client is not specified any requiremnt of NDE before or after PWHT , it shall understand that NDT shall be carried out after PWHT only.

Sourav Bohrays

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/7ace510e-aded-4ef9-a8d7-e05f15eb9af9n%40googlegroups.com.

pgos...@rogers.com

Hello Williams,

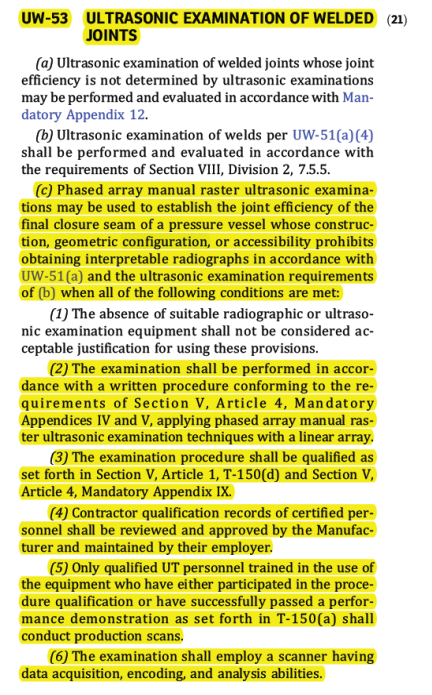

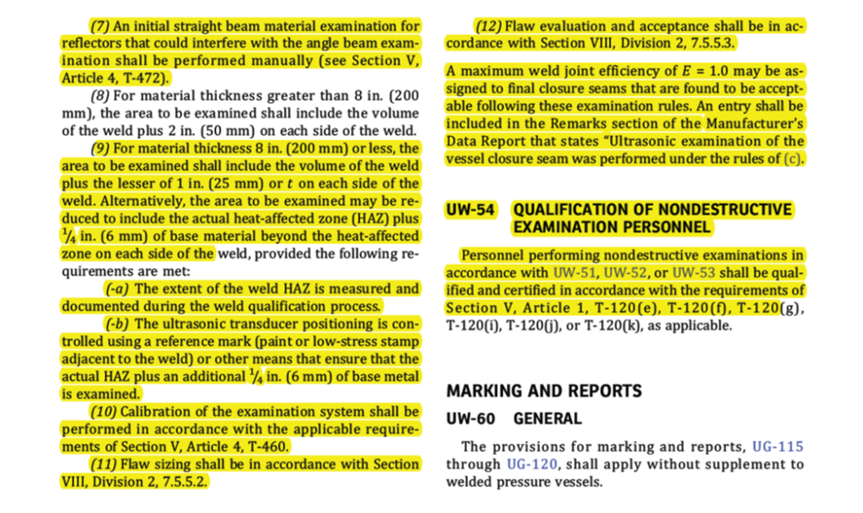

Sec VIII, DIV-1 allows PAUT in lieu of RT, subject to the fulfilment of the following clauses. Requirements are well documented. A competent organization, with qualified personnel and similar experiences are the key. Interpretation of PAUT is not very easy, defect sizing and acceptance requires skill. In RT you’re able to see the actual defect size, while in PAUT like any other UT technique it’s all signals.

In order to convince the inspector (AI) the actual clauses and reasons for not doing RT should be well referred in your proposal.

Thanks.

Pradip Goswami.P.Eng, IWE.

Cell/Whasapp:1-905-9793232

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAOWr6k_VAkf7q%2BsiMetZm7fxVo0NdMqqU-7a%2BjPObs1-f8uxjA%40mail.gmail.com.