Distance between two weld joint

425 views

Skip to first unread message

siva Guru

Oct 4, 2019, 7:19:10 AM10/4/19

to material...@googlegroups.com

Dear All

Can you advice,

two weld joint how much Min distance between weldjoints.

Please clarify, if possible please provide code reference.

Best regards

Guru

Hernan Arturo Castillo Mier

Oct 4, 2019, 7:33:17 AM10/4/19

to material...@googlegroups.com

Hello:

Hernán Castillo Mier

Ingeniero Senior Confiabilidad e Integridad

FACILITADOR AUTORIDAD TÉCNICA EQUIPO ESTÁTICO

INSPECTOR AUTORIZADO

API 510 (33119)

Avantel: 8*1571

Teléfono: 668-2396

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to

materials-weld...@googlegroups.com.

To view this discussion on the web visit

https://groups.google.com/d/msgid/materials-welding/CAEDN%2BXFp1f7duhV4NFBmu_87QNzsuA877q4wDUTDuEOPTOM7eQ%40mail.gmail.com.

Kannayeram Gnanapandithan

Oct 5, 2019, 4:02:16 AM10/5/19

to materials-welding

Ref BSEN 15952-5

Adam Janzeer

Oct 6, 2019, 11:40:43 PM10/6/19

to material...@googlegroups.com

Dear ALL

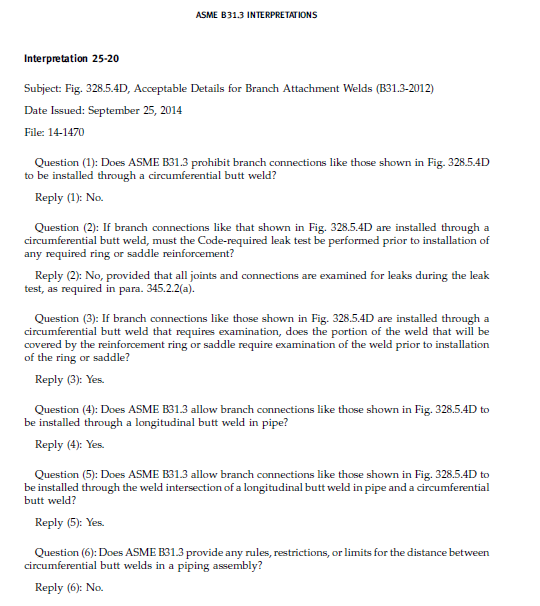

Longitudinal welds in two adjacent pipes should be 180° apart, but in any case shall be separated

by at least twice the wall thickness of the thicker pipe. When pneumatice leak test in accordance

with ASME B31.3, para. 345.4 is performed in lieu of hydrostatic leak test, the minimum spacing of

the longitudinal welds SHALL [PS] be followed.

If the pipe contains a longitudinal weld, this weld SHALL [PS] not be located at the bottom of the

pipe after installation; it should be located at least 45° from the bottom of the pipe.

As per my knowledge, It's a good engineering practice mostly highlighted on our project specification or client procedure.

For your reference refer below clause extracted from SHELL DEP 31380131

3.3 ASSEMBLY OF PIPING COMPONENTS

For butt-welding of all piping components (e.g. pipe ends, fittings and welding neck

flanges), a uniform root gap shall be provided as specified in the relevant Welding

Procedure Specification.

Flange bolt holes shall straddle the vertical centerline of the pipe where the flange is

installed vertically, and the north-south line where the flange is installed horizontally.

Refer to DEP 31.38.01.11-Gen. for flange misalignment acceptance criteria of misalignment

of flanges.

The minimum distance between the edges of two pressure-containing welds shall be twice

the wall thickness of the thicker pressure part. The same requirement applies to the

distance between non-pressure attachment welds and a pressure-containing weld in order

to allow non-destructive inspection of the pressure-containing weld.

For butt-welding of all piping components (e.g. pipe ends, fittings and welding neck

flanges), a uniform root gap shall be provided as specified in the relevant Welding

Procedure Specification.

Flange bolt holes shall straddle the vertical centerline of the pipe where the flange is

installed vertically, and the north-south line where the flange is installed horizontally.

Refer to DEP 31.38.01.11-Gen. for flange misalignment acceptance criteria of misalignment

of flanges.

The minimum distance between the edges of two pressure-containing welds shall be twice

the wall thickness of the thicker pressure part. The same requirement applies to the

distance between non-pressure attachment welds and a pressure-containing weld in order

to allow non-destructive inspection of the pressure-containing weld.

Longitudinal welds in two adjacent pipes should be 180° apart, but in any case shall be separated

by at least twice the wall thickness of the thicker pipe. When pneumatice leak test in accordance

with ASME B31.3, para. 345.4 is performed in lieu of hydrostatic leak test, the minimum spacing of

the longitudinal welds SHALL [PS] be followed.

If the pipe contains a longitudinal weld, this weld SHALL [PS] not be located at the bottom of the

pipe after installation; it should be located at least 45° from the bottom of the pipe.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4eNUW1PgOtT15%3D7FoAmVJkWrfEaE09ZrKguX_fqOoXKKTQ%40mail.gmail.com.

Maha Charu

Oct 6, 2019, 11:42:11 PM10/6/19

to material...@googlegroups.com

Good info

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/BN6PR2201MB1092167BC6C7B21E37C4CC6DDD9E0%40BN6PR2201MB1092.namprd22.prod.outlook.com.

mohsin tufail

Oct 9, 2019, 2:18:17 AM10/9/19

to material...@googlegroups.com

20mm or three times of the wall thickness which is greater

Adam Janzeer

Oct 9, 2019, 3:32:42 AM10/9/19

to material...@googlegroups.com

Dear moshin

Based on which reference....

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CADa_Lup61kGNBO2ZjNA-K9sXC5ia-qZwmKsX1dNcYHwdVa6tzg%40mail.gmail.com.

mohsin tufail

Oct 9, 2019, 11:14:46 PM10/9/19

to material...@googlegroups.com

reference aramco standard w-11

11.1

The minimum distance between parallel butt welds shall be 20 mm or

three times the wall thickness of the joint, whichever is greater

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAGKnWWjnnLYj%2B%3DnsHG-3SWmP3FYx0F8WXgbSNehb6iGEJLyi5g%40mail.gmail.com.

atul khatri

Oct 10, 2019, 1:57:31 AM10/10/19

to material...@googlegroups.com

Dear Siva,

You must be aware that min. separation distance between two welds is to isolate there heat affected zone (HAZ).

HAZ depends on so many factors out of which thickness is the key one.

So as Mohsin and Adam suggested, these requirements are mainly guided by client's specifications based on their practical experiences or lesson learnt.

So you could take gap between two welds as maximum between 50 mm (based on good engineering practice), twice the wall thickness of the thicker pressure part (As Adam advised) and 20 mm or three times the wall thickness of the joint (as Mohsin advised).

If you go with the above for sure you will not face any issue.

Also take note that if you are asking about the weld joints for piping spool, it will be good to have the minimum spool length as equal to pipe nominal diameter for 6" and above and for lesser size it should be 100 mm.

Thanks

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CADa_Luqyf0gQx678fZWLzsJuVXSz2kq%2BAX6t6uxwX1cw7bgCaA%40mail.gmail.com.

Kannayeram Gnanapandithan

Oct 10, 2019, 4:35:23 AM10/10/19

to materials-welding

As per DIn EN 12952-5,(2012) 8.1.7. should be greater than 40mm

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CACKOSeDLkY0c7Cmnz14cGOaNN5YYDGiXBHzSDf1MpUAhFCn%3DWg%40mail.gmail.com.

Paidi

Oct 11, 2019, 1:42:37 AM10/11/19

to material...@googlegroups.com

Dear Shiva

Please see your project specification ....Distance between weld join will varies as per Client standards...

In general ..3 times of WT should be required ...

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAEDN%2BXFp1f7duhV4NFBmu_87QNzsuA877q4wDUTDuEOPTOM7eQ%40mail.gmail.com.

Thanks & Best Regards,

Suresh Paidi

Suresh Paidi

Reply all

Reply to author

Forward

0 new messages