interpass temperature

934 views

Skip to first unread message

Rameez khan RK

Aug 22, 2021, 11:10:39 PM8/22/21

to Materials & Welding

Hello Experts,

Can any one tell me about interpass temperature for carbon steel pipe as [per code and standards.

WE facing one issue here our Approved PQR interpass temp. is 290 but in WPS its mention 340 c so please defined and what is actually interpass temp as per codes per standards.

thank you

james gerald

Aug 23, 2021, 4:10:12 AM8/23/21

to material...@googlegroups.com

Interpass temperature is the temperature measured after welding of each pass. (please refer for definition of each pass in welding). Normally before you start welding you apply PREHEAT and this becomes the minimum Preheat temperature and after start of welding due to the high Arc temperature the welding heat will be conducted and after completion of one pass say for example Root pass one shall measure the temperature on the weld bead(root bead). Like wise for each pass the interpass temperature shall be measured. Welding shall be performed for all passes between minimum Preheat Temperature and maximum Interpass temperature measured at the start of each pass. Interpass temperature is measured after completion of one pass and whereas welding preheat during welding shall never be less than minimum preheat temperature.

Effect of Interpass temperature on Carbon steel.

1. Higher the Interpass temperature, then slower the weld cooling rate which inturn results in Higher Grain size in the finished bead/weld and lesser the Charpy Impact values.

2. According to ASME Sec.IX, increase in Interpass temperature higher than 55degC than the PQR will be considered an Supplementary Essential variable and requires new qualification of PQR. Any changes in the maximum Interpass temperature within 55degC (PQR) shall be revised in the WPS.

3. Your case 290degC is well within the maximum Interpass temperature of 340degC mentioned in the WPS and so there is no issue.

Thanks & Regards

J.Gerald Jayakumar

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/0c475dd0-ecd8-497c-a281-d0094ac7fa61n%40googlegroups.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/0c475dd0-ecd8-497c-a281-d0094ac7fa61n%40googlegroups.com.

GENE MATSKO

Aug 23, 2021, 4:10:12 AM8/23/21

to material...@googlegroups.com

Interpass temperature is defined in QW/QB-492. Measurement of it can be made using Temperature indicating crayons, contact or infrared pyrometers, etc. It need not be measured during procedure qualification or recorded on the PQR unless impact testing is required. It is also an essential variable fpr Weld Overlay qualification.

Gene Matsko

--

Chetan Kapadia

Aug 23, 2021, 4:10:12 AM8/23/21

to Materials & Welding

Dear Rameez khan RK,

Interpass temperature is generally mentioned as MAXIMUM.

Hence Approved PQR interpass temp. is 290 but in WPS its mention 340 c is acceptable.

Please note that code has specifically mentioned as important criteria when impact test is essential in application.

It is a delicate balance between time & temperature for preheat, post heat cooling rate, Thickness, Heat Input, Ambient Conditions & Heat Transfer.

The WPS & PQR is the basis of the starting point for establishing design requirements. At times simulations tests are carried out to ensure & impose limit on preheat, interpass temperature control & PWHT requirement to regain requisite material properties in as delivered conditions of final equipment / structures. Hence it is a designer driven MOC & welding technology fulfillment to achieve desired end results.

The application can vary from structure, Pressure vessels, aero, nuclear, defense & rocket to several others using welding as technology.

The result of interpass is measured by Final Hardness in parent material, HAZ & weld metal as per specified by designer.

Attached please find extract of general theory regarding understanding of interpass temperature requirement.

Best Regards,

C.B.KAPADIA

C.B.KAPADIA

--

james gerald

Aug 23, 2021, 4:10:22 AM8/23/21

to material...@googlegroups.com

Just to add,

Your PQR temperature is 290 and according to ASME Sec.iX it can be increased to 345max in the WPS if Charpy Impact test is Applicable else even more.

Thanks & Regards

J.Gerald Jayakumar

--

Gerry Lourens

Aug 23, 2021, 4:10:22 AM8/23/21

to material...@googlegroups.com

|

Hi

Interpass temperature is an supplementary essential variable , thus when toughness is required it is an essentiaslvariable and may be increased with 55 degrees. When toughness is not required it is not a variable to be considered

Regards

|

Best Regards, |

||

|

Gerry Lourens Welding Engineer New Age Engineering Solutions |

|

|

||

|

A: 3 York Street, Evander, 2280 |

||

|

||

--

Tajuddin Mohammed

Aug 26, 2021, 11:12:14 PM8/26/21

to material...@googlegroups.com

As per Aramco Standard SAES-W-11 the maximum interpass temperature for P1 material is 315 degree celsius, and P8 material is 177 degree celsius.

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/0c475dd0-ecd8-497c-a281-d0094ac7fa61n%40googlegroups.com.

Thanks & Regards

Mohammed Tajuddin

WELDING INSPECTOR CSWIP 3.1

Contact 0508780633

JUBAIL

Gerry Lourens

Aug 26, 2021, 11:57:20 PM8/26/21

to material...@googlegroups.com

|

Hi

the client specification is more stringent than the code , Thus according to the Client spec 315 is the maximum interpass temperature,. revise the WPS

Regards

Gerry Lourens

|

Best Regards, |

||

|

Gerry Lourens Welding Engineer New Age Engineering Solutions |

|

|

||

|

A: 3 York Street, Evander, 2280 |

||

|

||

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CACZrEUbtuZ3pt%3DskFRaPkT5DpKQY3rqZStB5N_VF4KsG-m2hFg%40mail.gmail.com.

Kannayeram Gnanapandithan

Aug 27, 2021, 12:13:11 AM8/27/21

to materials-welding

Ref QW 406.3. From Qualified PQR, u can add 55 deg celsius than PQR in WPS. If client has already given the maximum interpass temp, u can revise WPS with revised interpass temp. NO issue at all

THANKS & BEST REGARDS,

KG.PANDITHAN, BE, IWE, CSWIP 3.1,

ISO 9712 Level 2 in VT,

ASNT-Level II in PT,MT,RT & UT,

LA ISO 9001-2015,

International Welding Engineer.

CONSULTANT-WELDING & QUALITY

Mobile no: +919940739349

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAFgehWdjoe%2Bd_VpyJwHDAuHbMtcR%2BbEROUxCh7DSBCs4d%3DS3Ug%40mail.gmail.com.

james gerald

Aug 27, 2021, 3:51:30 AM8/27/21

to material...@googlegroups.com

Client specification always takes precedence and is mandatory.

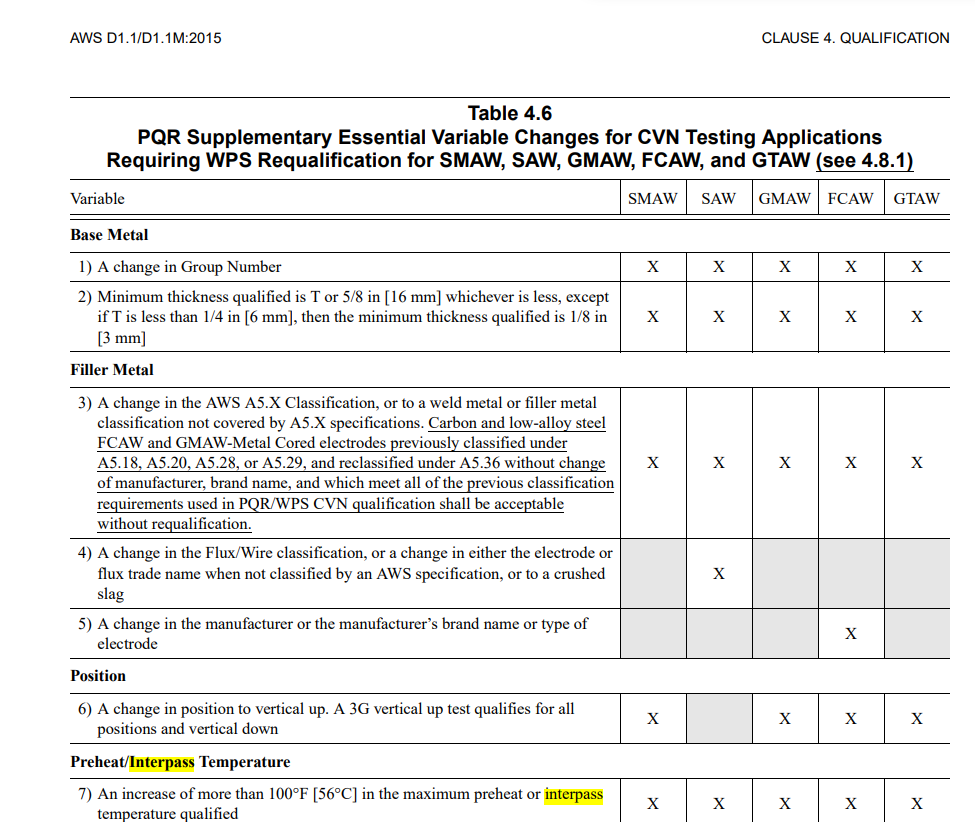

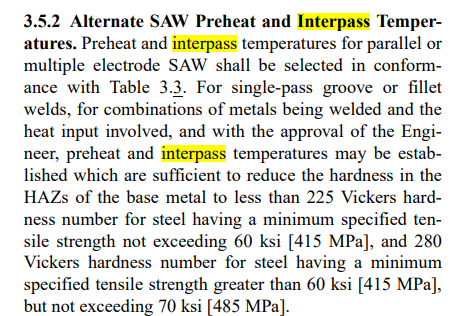

For structural Application according to AWS D 1.1 gives the same requirement.

Maximum interpass temperature according to AWS D1.1 as mentioned in it based on Hardness value;

Please select based on the requirement.

Thanks & Regards

J.Gerald Jayakumar

--

Mhaskar Aly

Dec 9, 2021, 10:21:21 PM12/9/21

to material...@googlegroups.com

Hi

Interpass temperature is the maximum temperature of the joint before starting 2nd Run of welding.Preheat temperature is the minimum temperature of the joint before starting of 1st Run of welding

Interpass temperature is supplementary essential variable as per ASME SecIX hence no need to address on WPS where impact test is not applicable.

Mhaskar Ali

Dubai

--

Reply all

Reply to author

Forward

0 new messages