Impact testing - V NOTCH CHARPY. Recommendation

248 views

Skip to first unread message

Prats

Dec 4, 2023, 6:36:33 AM12/4/23

to Materials & Welding

Hello,

We have an impact testing requirement to be done on a pipe with an outer diameter of 60mm and a thickness of 5.5mm.

What specimen size should we select for the testing? As the standard "ASTM E23-23A" states, specimen size should be 55L x 10W x 10 thick. We are a bit confused regarding the specimen size...has anyone faced a similar issue? please recommend

Moreover, the specimen should sustain 27 J.

Please help.

Thanks & Regards

Prats

Pravin Kurade

Dec 4, 2023, 7:00:37 AM12/4/23

to material...@googlegroups.com

You can take subsize specimen provided take consideration of thickness reduction

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/d6ea2566-4818-419b-9dcf-d307c61bab53n%40googlegroups.com.

james gerald

Dec 4, 2023, 7:00:37 AM12/4/23

to material...@googlegroups.com

A Charpy Impact test is not required for specimen thickness less than 2.5mm.

Subsize specimens can be machined from the Pipe OD 60mm and thickness 5.5mm. Please check with the Mechanical testing lab.

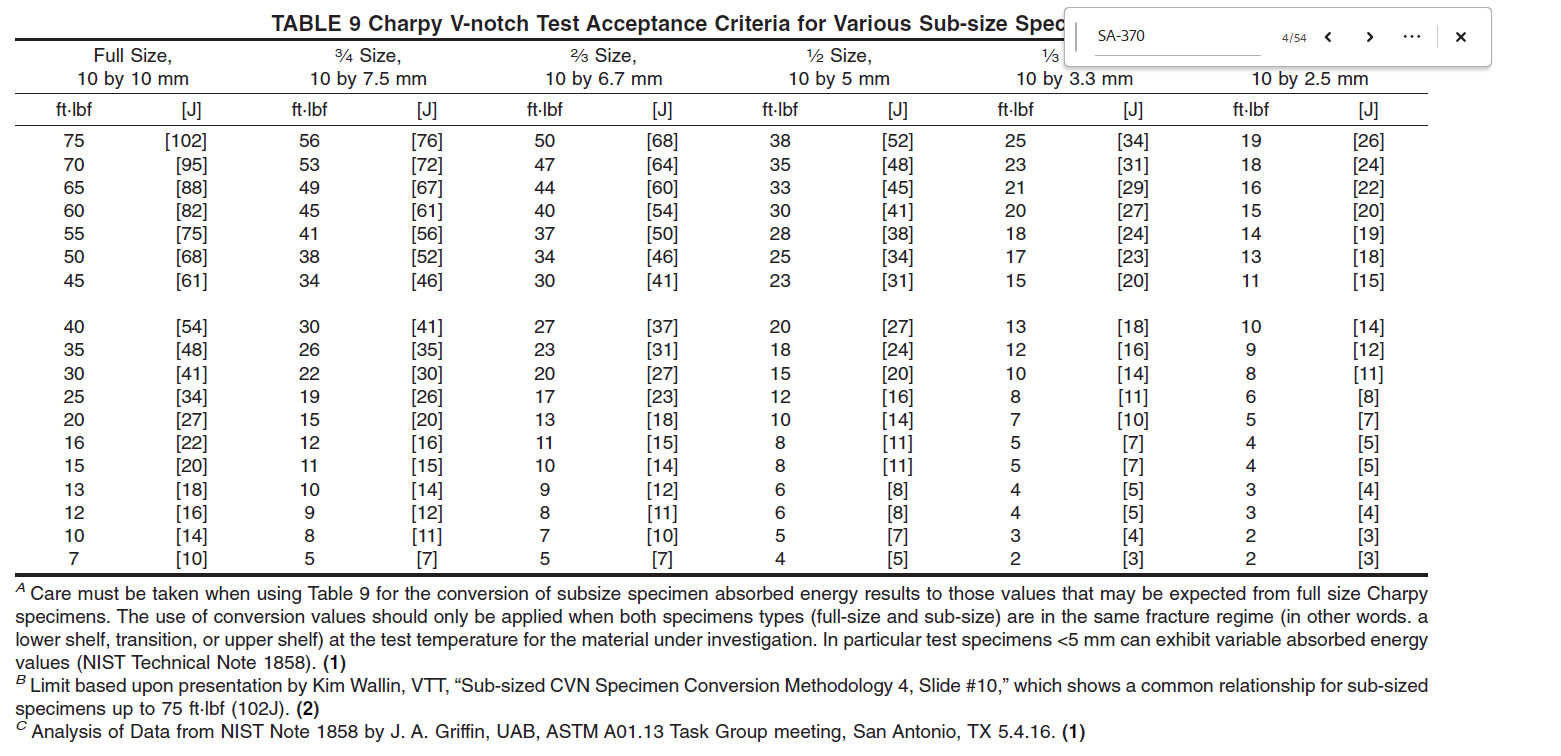

Please refer to ASME Sec.IIA section SA-370.

If specimen thickness exceeds 80% during machining from the original size, temperature reduction according to the Applicable Code shall be applied.

For subsize specimens Impact values refer to snap shot.

Thanks & Regards

J.Gerald Jayakumar

--

Vishwas Keskar

Dec 4, 2023, 7:00:37 AM12/4/23

to material...@googlegroups.com

You can take subsize

Refer SA 370

3.3 or 2.5mm

Sent from my iPhone

On 04-Dec-2023, at 5:06 PM, Prats <prathame...@swastikindustriesindia.in> wrote:

Hello,

--

Prathamesh Patkar

Dec 5, 2023, 11:04:48 PM12/5/23

to material...@googlegroups.com

Dear Sir,

Thank you for the response.

I had one more query. Are there any acceptance criteria for minus temperature? eg... the specimen should sustain 12 J impact at -20c in order to qualify.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/598336985.6110574.1701690837182%40mail.yahoo.com.

Regards,

Thanks & Regards

Prathamesh S Patkar

james gerald

Dec 6, 2023, 10:23:26 AM12/6/23

to material...@googlegroups.com

Normally either from the Process or Mechanical Designer will provide the MDMT ( Minimum Design Metal Temperature) - it is the lowest temperature attained by the Material either due to Process conditions / Environmental conditions / upset conditions. So Impact testing has to be performed at MDMT.

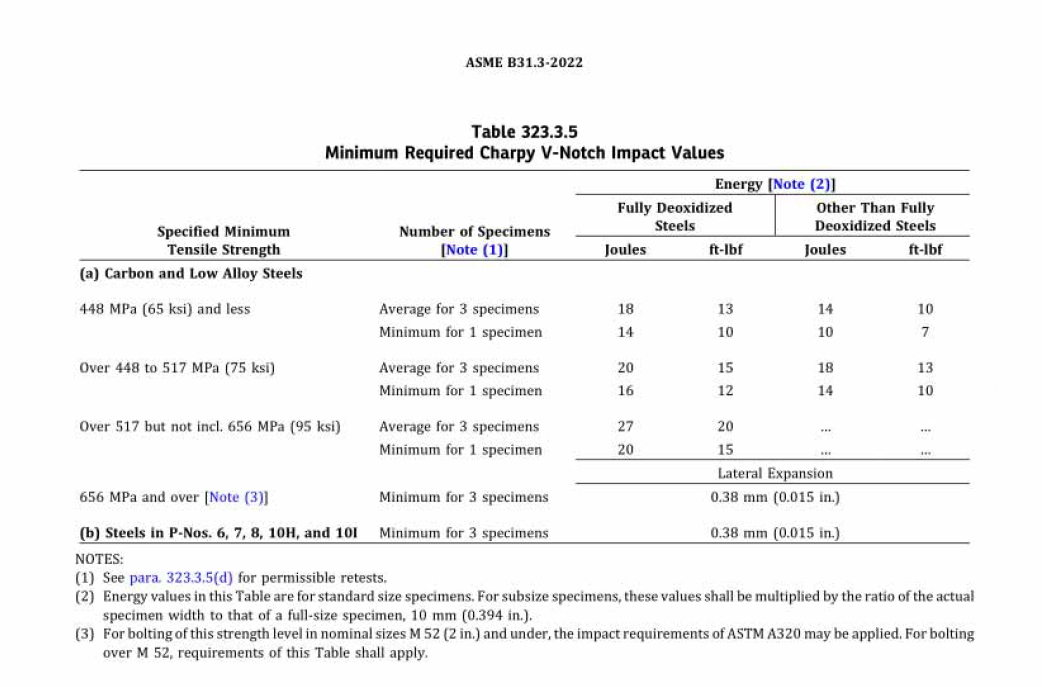

Charpy Impact values for Full size specimen (10x10x55) will be specified either by the Design Code or superceded by the Client specification if provided. Test Temperature MDMT.

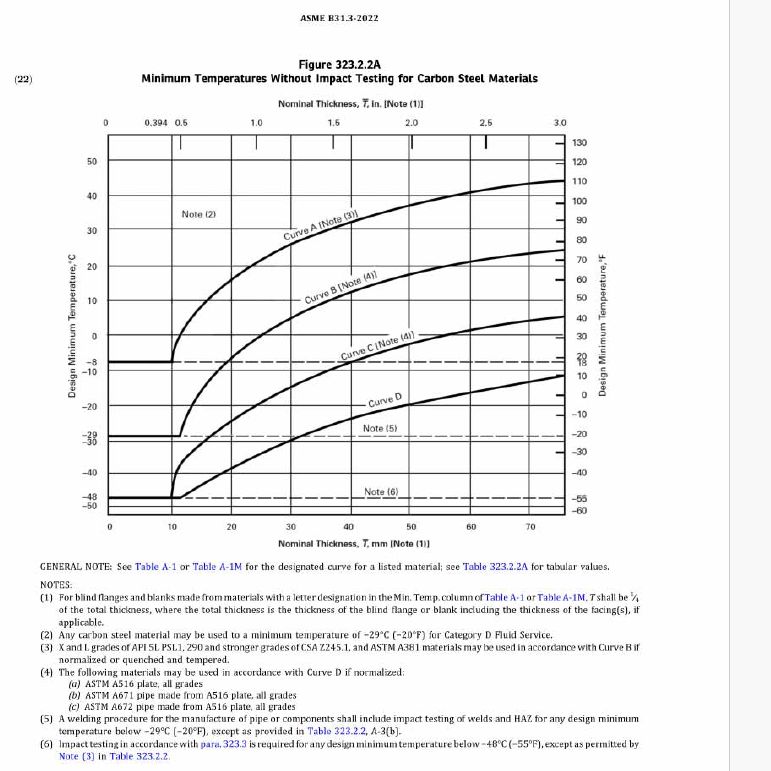

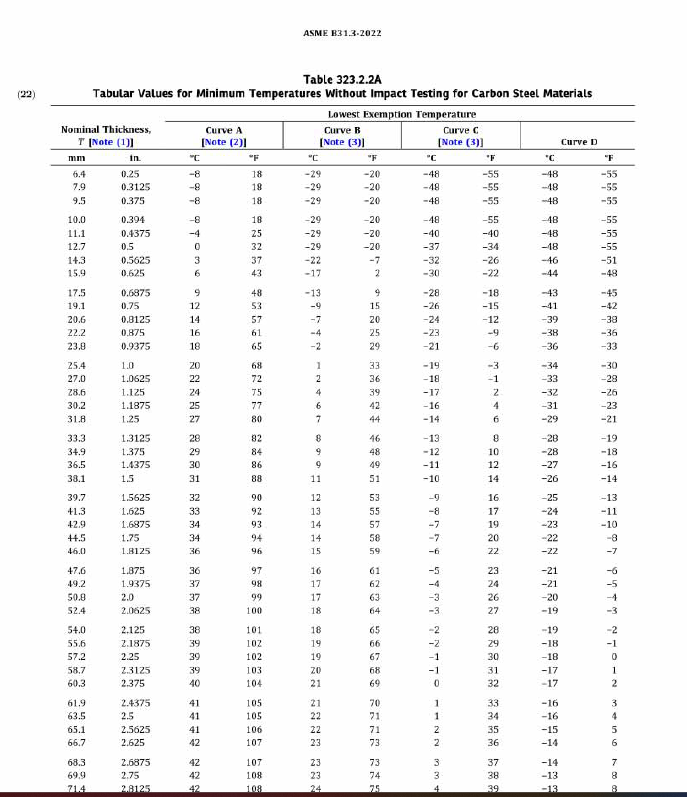

A Snap shot of ASME B 31.3 is given as example below.

Thanks & Regards

J.Gerald Jayakumar

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAC4daO1FWBtE5gfLNgNYqhsVg%2Bu0V475C3r53uDxgj82GDtq8A%40mail.gmail.com.

james gerald

Dec 6, 2023, 10:23:27 AM12/6/23

to material...@googlegroups.com

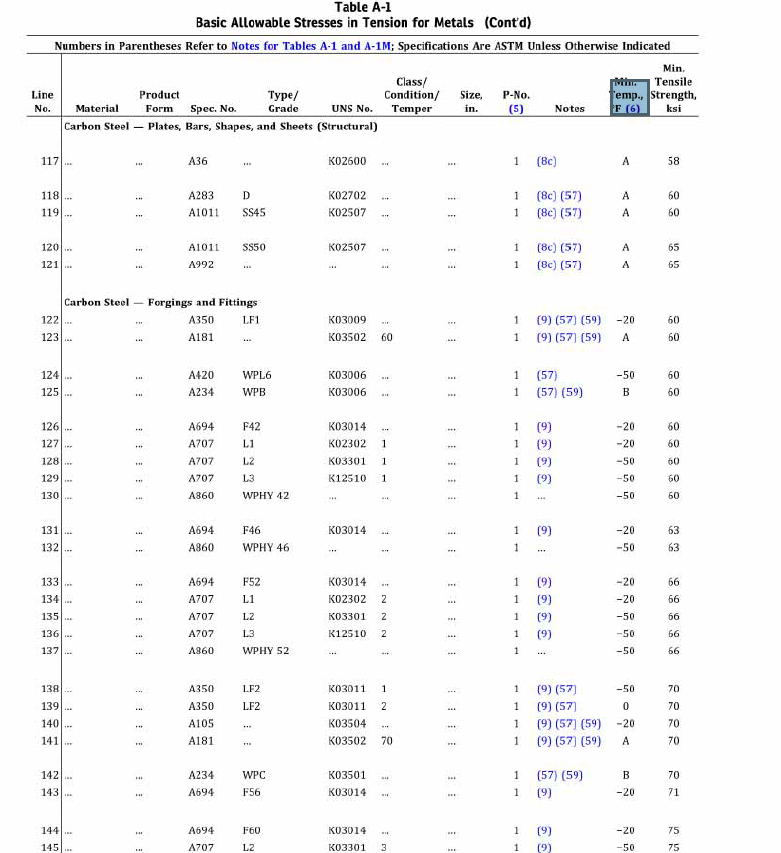

Just to add. From your Question I assume you are using a code such as B31.3 which gives the requirement for the Material specification whether Impact testing is required based on the Job Thickness. In B31.3 there is a stress table which for carbon steels provide Grahs A B C D or the minimum temperature the material requires impact testing.

A snap shot provided below.

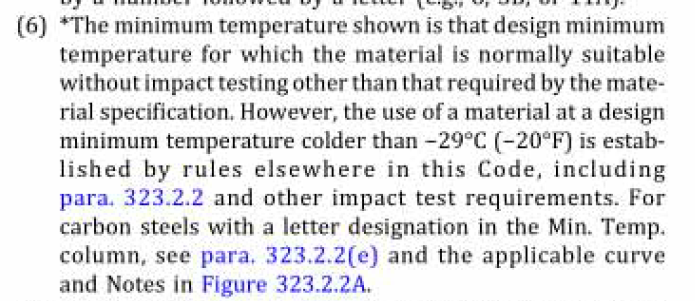

Please also see the snapshot of Note 6 highlighted above.

Snap shot of Curve

Subsize Charpy impact value provided in my First mail

Thanks & Regards

J.Gerald Jayakumar

On Wednesday, 6 December, 2023 at 09:34:42 am IST, Prathamesh Patkar <prathame...@swastikindustriesindia.in> wrote:

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAC4daO1FWBtE5gfLNgNYqhsVg%2Bu0V475C3r53uDxgj82GDtq8A%40mail.gmail.com.

Reply all

Reply to author

Forward

0 new messages