PWHT exemption in ASME B31.3

160 views

Skip to first unread message

Anilkumar G

Aug 25, 2022, 5:50:58 AM8/25/22

to Materials & Welding

Dear Experts

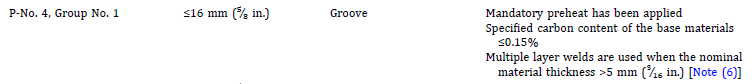

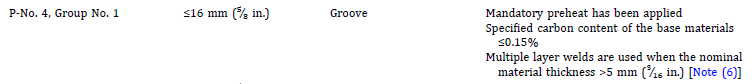

As per ASME B31.3 table 331.1.3, for alloy steels, PWHT is exempted if thickness <=16mm based on some conditions.

One of the conditions for exemption is the use of multiple layer welds when nominal thickness is greater than 5mm. Whether this condition is to ensure that weld layers are tempered, so that martensitic structure wont be formed? If so what about the final layer of the weld, which would be still left untempered?

Regards

Anilkumar

Sudhakar Kuppuswamy

Aug 25, 2022, 11:45:16 PM8/25/22

to material...@googlegroups.com

Hi,

For Pno 4 (let say P11 grade ),Achieving hardness and toughness without PWHT is really a challenging task.

Preheat temp and methodology plays a vital role.

Try to use induction heating!

If the impact test at minus 29 C is required, then there is not point in trying without a PWHT.

Yes, for the cap pass , temper bead techniques will help greatly .

In PQR we can do things with lot of care and somehow achieve the required results , but in production each and every joint needs to welded with same care , which may not be easy to do.

Hence, in my opinion going with PWHT is a good option. Check API RP 582, It mandates. ( I presumed API RP 582 will also be applicable)

Regards,

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/882c4f38-f7f2-4a4b-af0d-6374e93964c5n%40googlegroups.com.

Sudhakar Kuppuswamy

Aug 25, 2022, 11:45:16 PM8/25/22

to material...@googlegroups.com

Just to add one key point: while approaching for the final cap pass, deliberately increase the pre- heat temp to the maximum acceptable range and apply temper bead techniques, so you can keep the last pass hardness under control.

The above may help to an extent. However, if CVN impact at minus 29 Deg C is applicable. PWHT is only option.

Regards,

Reply all

Reply to author

Forward

0 new messages