Impact testing as per ASME B31.3

2,206 views

Skip to first unread message

Babur Khan

Jul 31, 2019, 3:24:42 AM7/31/19

to material...@googlegroups.com

Dear experts,

Please clarify for impact test requirements of below variables.

Construction code ASME B31.3

Material A106 Gr. B

The thickness of Pipe. 17.48 mm

Temperature Limit 0^ F (-17.78^ C)

PWHT yes.

Table A-1 refers to curve B

Table 323.2.2A minimum Temperature without Impact Testing for CS showing under curve B 9^ F ( 12.8^ C).

My Question is for above case Impact testing for WPS qualification is required?

Please clarify for impact test requirements of below variables.

Construction code ASME B31.3

Material A106 Gr. B

The thickness of Pipe. 17.48 mm

Temperature Limit 0^ F (-17.78^ C)

PWHT yes.

Table A-1 refers to curve B

Table 323.2.2A minimum Temperature without Impact Testing for CS showing under curve B 9^ F ( 12.8^ C).

My Question is for above case Impact testing for WPS qualification is required?

Regards,

Muhammad Babur Khan Lashari

Sr. QA/QC Inspector (Welding)

(CSWIP 3.1 / CWI II From PWI)

Mob: + 966 58 2774568 / 050 5193275

PAK : + 92 334 6186285 (Whatsapp)

Skype: babur.lashari

Sudhakar Kuppuswamy

Jul 31, 2019, 4:25:31 AM7/31/19

to google welding

In my opinion, for the below stated conditions, as per ASME B31.3, Impact test is applicable. I.e. supplementary essential variables for ASME Section 09 becomes essential variables.

And, the qualified WPS thickness shall be T/2 to T+6mm, i.e. 8.74 mm to 23.48 mm in your case.

Regards,

Sudhakar K

Welding Engineer

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAN53wK1Vs8CgXP0uzAFyPAUNQ-gbaeg7axU9zRQZsXhV9p19jg%40mail.gmail.com.

pradip kumar Sil

Aug 1, 2019, 12:19:56 AM8/1/19

to materials-welding

Can you pls give reference for qualification thickness in this case

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CA%2BfZfcPjTGp6RdR8Q_-4Q%2B_AxS3cG4_scXWH2m-b3fW-5apgzg%40mail.gmail.com.

Babur Khan

Aug 1, 2019, 6:31:25 AM8/1/19

to material...@googlegroups.com

Dear Mr. Kumar,

Base metal thickness is 3.73 to 17.48mm

Muhammad Babur Khan

Sent from my iPhone

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAB%3DAs8ko-s%3DXUi90qaiSkw43p_dXnuWxb7k1oom%3DhxNtfFkhRQ%40mail.gmail.com.

Sudhakar Kuppuswamy

Aug 1, 2019, 6:31:28 AM8/1/19

to google welding

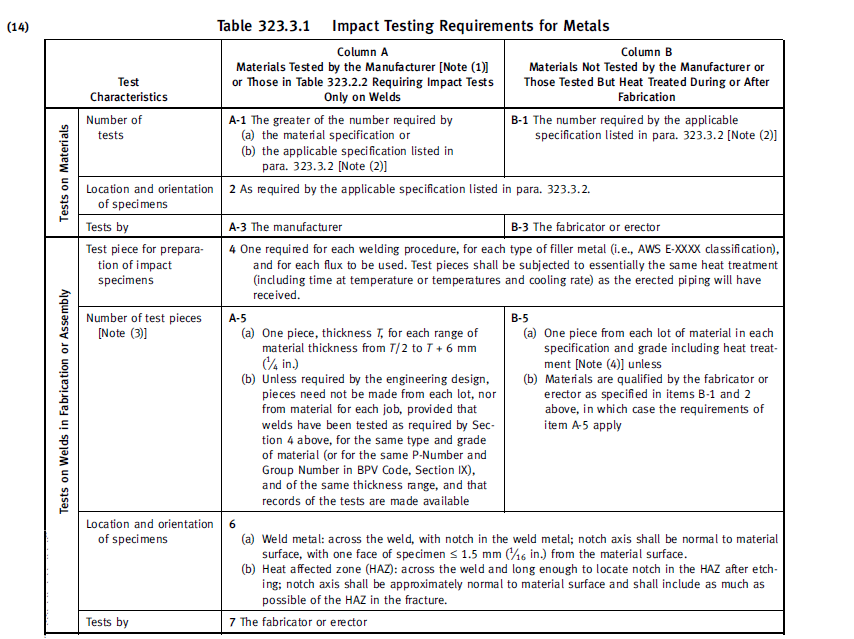

You may please refer to Table 323.3.1 Impact Testing Requirements for Metals of ASME B31.3, Chapter 3.

Below is the snapshot, Refer A.5

Regards,

Sudhakar K

Welding Engineer

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAB%3DAs8ko-s%3DXUi90qaiSkw43p_dXnuWxb7k1oom%3DhxNtfFkhRQ%40mail.gmail.com.

حرف راز

Aug 2, 2019, 4:04:12 AM8/2/19

to material...@googlegroups.com

Dear sudhakar k,

very good reference but how can you relate this to WPS

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CA%2BfZfcP0-RffjshZenc%2BQOKMtknKLVJ7Owz4k6WW%2BPP-zb7OEA%40mail.gmail.com.

Khaled lamraoui

Aug 2, 2019, 4:04:12 AM8/2/19

to Materials & Welding

Dear experts. I need your help please. I have sa 335 p91 as base material used in power plant does this require impact test for preparation of pQR or not? Ps: used for high temperature applications 600 degree. Can you please give a detailed explanation. Khaled lamraoui.

anand gupta

Aug 2, 2019, 9:54:58 AM8/2/19

to material...@googlegroups.com, Khaled lamraoui

As per code for high temp impact test no need.

Impact need for low temp only.

Regards

On Fri, 2 Aug 2019 at 13:34, Khaled lamraoui<eurl...@gmail.com> wrote:

Dear experts. I need your help please. I have sa 335 p91 as base material used in power plant does this require impact test for preparation of pQR or not? Ps: used for high temperature applications 600 degree. Can you please give a detailed explanation. Khaled lamraoui.

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-welding+unsub...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/88a57bae-9e31-4ebc-8c66-1ec9124eb25f%40googlegroups.com.

Dinesh Somwanshi

Aug 2, 2019, 9:55:00 AM8/2/19

to materials-welding

Dear sir,

Impact testing Its based on Mean design temperature cycle defined in drawing & If any project specs.

Thanks & Regards

DINESH VITTHAL SOMWANSHI

BACHELOR IN MECHANICAL ENGINEER

असो द्यावी दया तुमच्या लागतसे पाया.

*Pray for others, sometime, You might never need to pray for yourself

again.....*

BACHELOR IN MECHANICAL ENGINEER

असो द्यावी दया तुमच्या लागतसे पाया.

*Pray for others, sometime, You might never need to pray for yourself

again.....*

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAGppVaoUm2F0AV6-qwmMGKVrP5rVs5ifRX3g4z6kHCZMfDXMCw%40mail.gmail.com.

Kannayeram Gnanapandithan

Aug 2, 2019, 12:02:52 PM8/2/19

to materials-welding

Check consumables are impact tested at room temperature. That's enough

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/194641271.359695.1564750983528%40mail.yahoo.com.

Reply all

Reply to author

Forward

0 new messages