IMPACT TEST FAILLURE

125 views

Skip to first unread message

QA/QC

Oct 7, 2021, 4:23:35 AM10/7/21

to Materials & Welding

DEAR MASTER

we have a test coupon 7.11 thichness with flange a106 with a105n

during mechanical test the impact test for FLANGE FAILLURE IN HAZ IN 3 POINT £

IS IT ACCEPTABLE

J Prinsen

Oct 7, 2021, 5:32:25 AM10/7/21

to materials-welding

No it is not,

Something went wrong with the thermal cycle during welding, heat-input/interpass to high will break down the impact thoughness

Regards

Jurgen Prinsen IWE

Metallurgist and welding engineer

Van: "QA/QC" <adnan...@gmail.com>

Aan: "materials-welding" <material...@googlegroups.com>

Verzonden: Donderdag 7 oktober 2021 10:16:23

Onderwerp: [MW:32549] IMPACT TEST FAILLURE

Aan: "materials-welding" <material...@googlegroups.com>

Verzonden: Donderdag 7 oktober 2021 10:16:23

Onderwerp: [MW:32549] IMPACT TEST FAILLURE

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/b6717387-54eb-4c06-9748-9d4eddf4497dn%40googlegroups.com.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/b6717387-54eb-4c06-9748-9d4eddf4497dn%40googlegroups.com.

Prakash Hegde

Oct 7, 2021, 7:34:16 AM10/7/21

to material...@googlegroups.com

Hi

In addition some time there is possiblity of improper.Heat treatment received to Forging and casting causing non uniformity of.req.grain structure for total cross section Causing failure in Impact test

Regards

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/2010972503.6336922.1633599000093.JavaMail.zimbra%40online.nl.

Ahmed Rashed

Oct 7, 2021, 11:14:44 PM10/7/21

to material...@googlegroups.com

Dears,

I made PQR material A333 GR.6 (6" STD) welded by GTAW for Root pass (ER70S-6) and SMAW (E7018-1) for filling and cap according to ASME IX , B31.3.

Tensile test and bend test passed.

Impact test failed (for weld metal Av. 12 J) and for (HAZ Av. 8 J) at -55.6 degree celsius.

I don't know why the impact test failed !!!!!

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1007717278.245272.1633605838398%40mail.yahoo.com.

james gerald

Oct 7, 2021, 11:44:45 PM10/7/21

to material...@googlegroups.com

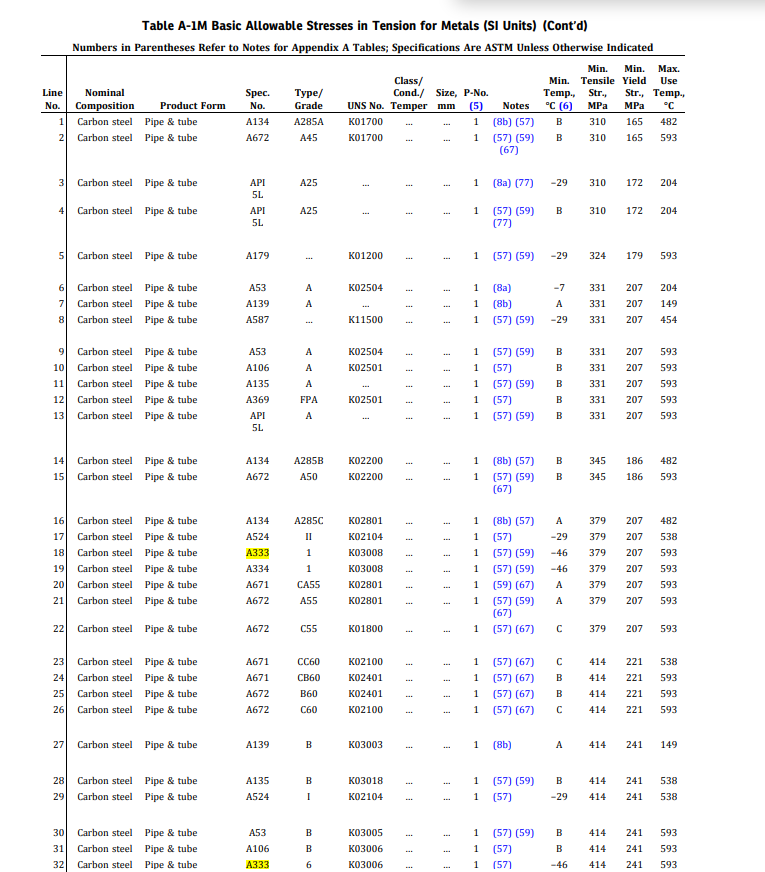

A333 Gr.6 is permitted by ASME B31.3 to be used at minimum temperature of -46degC. See snap shot below.

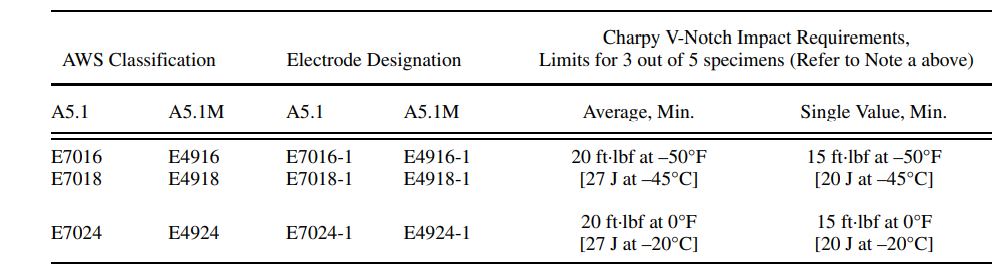

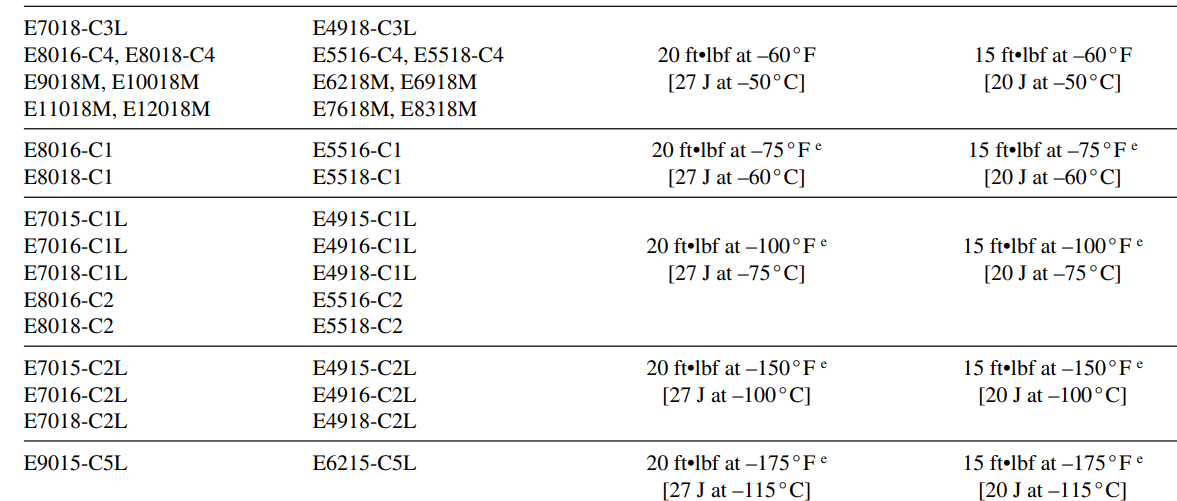

Moreover please look below for the limits of welding consumable.

E7018 can be used only upto -45degC. See snapshot below.

For lower temperatures please go for Nickel based steel consumables. see snap shot below.

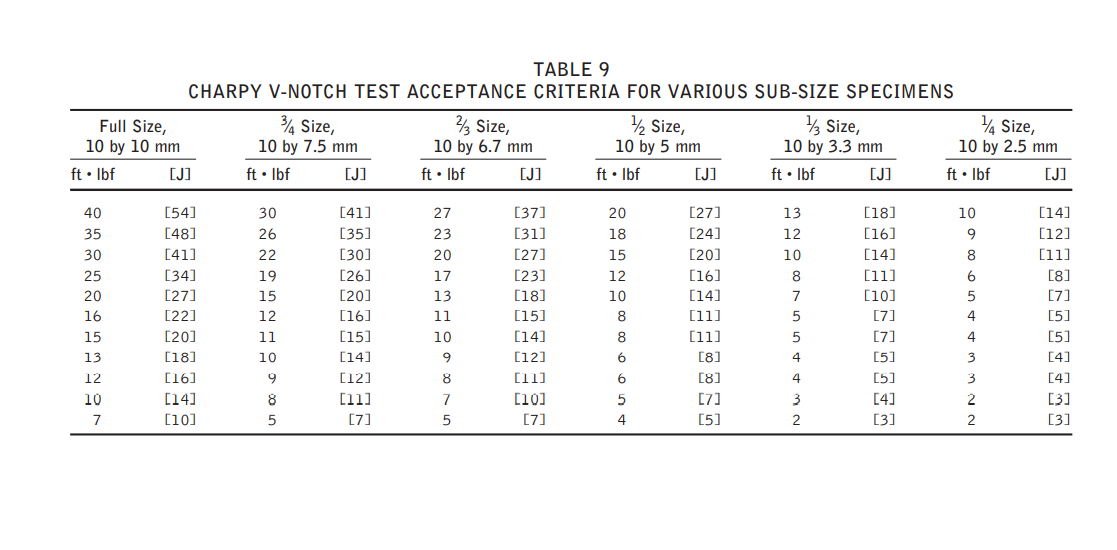

If your case is a subsize specimen with temperature reductions, then review your welding conditions carefully.

Thanks & Regards

J.Gerald Jayakumar

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAHgdUykpKMDA8ndCWAuY4Fwkhu-dT3nHB7%3Dj8RpuTocKv980Og%40mail.gmail.com.

Perumal Govindan

Oct 8, 2021, 12:26:41 AM10/8/21

to material...@googlegroups.com

Hi

Please let me know the following:

1. Min and max UTS of the actual project material ( refer all the batches / heat numbers of MTCs) was manufactured and hope the same material was used to run the PQR/PQT.

2. What is the application of the material and the MDMT.

Above information is required for the welding consumables selection.

ER70S-6 is having high carbon compared to ER70S-2. So ER70S-6 is not preferrable for ASTM A333 Gr. 6 root runs.

Also, E7018-1 can be used until 70KSI of your project material UTS, if the actual UTS exceeds, we have to choose other electrode.

Regards

Perumal Govindan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAHgdUykpKMDA8ndCWAuY4Fwkhu-dT3nHB7%3Dj8RpuTocKv980Og%40mail.gmail.com.

james gerald

Oct 8, 2021, 1:39:41 AM10/8/21

to material...@googlegroups.com

Just to add if you are using a subsize specimen then below snapshot values are Applicable.

Thanks & Regards

J.Gerald Jayakumar

Kannayeram Gnanapandithan

Oct 8, 2021, 2:45:13 AM10/8/21

to materials-welding

7018-1 is not for more than -45 deg celsius

THANKS & BEST REGARDS,

KG.PANDITHAN, BE, IWE, CSWIP 3.1,

ISO 9712 Level 2 in VT,

ASNT-Level II in PT,MT,RT & UT,

LA ISO 9001-2015,

International Welding Engineer.

CONSULTANT-WELDING & QUALITY

Mobile no: +919940739349

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAHgdUykpKMDA8ndCWAuY4Fwkhu-dT3nHB7%3Dj8RpuTocKv980Og%40mail.gmail.com.

Ramon Briceno

Oct 9, 2021, 12:36:37 AM10/9/21

to material...@googlegroups.com

Dear Ahmed,

Please use E-8018-C1, it contains Ni 2.5% which is good to better thougness until -60C.

E-7018-1 is limited -45C. It contains high Mn (1.6 %) only. Enough to get good thougnees until -45C.

Regards,

Ramon Briceno

Metallurgical Engineer

Enviado desde mi smartphone Samsung Galaxy.

-------- Mensaje original --------

De: Ahmed Rashed <ara...@qituv.com>

Fecha: 2021/10/07 11:14 PM (GMT-04:00)

Asunto: Re: [MW:32552] IMPACT TEST FAILLURE

To view this discussion on the web visit

https://groups.google.com/d/msgid/materials-welding/CAHgdUykpKMDA8ndCWAuY4Fwkhu-dT3nHB7%3Dj8RpuTocKv980Og%40mail.gmail.com.

Mohd Siraj

Feb 9, 2022, 2:54:36 AM2/9/22

to Materials & Welding

check flange Mn %..if less than 1 ,there is strong chance of failure.. procure flange wit more than 1.05% Mn.

Vishwas Keskar

Feb 9, 2022, 3:37:27 AM2/9/22

to material...@googlegroups.com

THK 7.11 mm

Following information is required

At what temperature Impact was carried out?

What is the impact sample size when tested ?

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1007717278.245272.1633605838398%40mail.yahoo.com.

Mohd Siraj

Feb 14, 2022, 12:15:09 AM2/14/22

to Materials & Welding

impact test shall be minimum design temp or mentioned in spec.

for size and 10x10x55 if not possible , you can use reduece size , in your case 5.5 is possible so need to consider reduce temperature...this all thing lab will take care!..

Reply all

Reply to author

Forward

0 new messages