SMALL DIAMETER PROCEDURE QUALIFICATION AS PER ASME SEC IX

268 views

Skip to first unread message

Vishwas Keskar Welding Manager WELDING

Mar 17, 2021, 11:07:46 PM3/17/21

to Materials & Welding

Dear Experts ,

6.35 mm OD X 0.89 mm thickness

Welding Process - Autogenous Fusion - GTAW Orbital WELDING

Code - ASME SEC IX

Material - SA 213 TP316L

Tensile test - 2nos

Face bend test - 2nos

Root bend test - 2nos

Full section tensile test is carried out and found satisfactory

Bend test samples can not be prepared due to less thickness(0.89mm) and small diameter (6.35mm). Pipe Sectioning as per permitted by ASME for small diameter is tried but could not do it .

When tried to cut into sectioning for bending test piece preparation , pipe is getting bent and sectioning is not possible .

Experts , Pl. help how to go about bend testing or any other way forward

José Juan Jiménez Alejandro

Mar 18, 2021, 11:20:56 PM3/18/21

to material...@googlegroups.com

I think you are complicating your life more than necessary, to do the bending and tension tests that your PQR needs per ASME IX requirements, you can use a tube of greater diameter and thickness of the same P number or if you like the same material, that will allow you to do your tests without any problem or setback, that is completely valid and design and write your WPS according to: thickness (0.89mm) and small diameter (6.35mm), your laboratory tests do not have to be strictly under these parameters: thickness (0.89mm) and small diameter (6.35mm).

Greetings!.

Greetings!.

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/6e39e586-dc33-4c22-a83e-30255b37a887n%40googlegroups.com.

Ing. José Juan Jiménez Alejandro

Independent Consultant in Parts

and Pressure Equipment

SUMMIT MÉXICO - TPI

https://www.linkedin.com/in/summit-m%C3%A9xico-tpi-760047137/

Móvil +52 1 812 352 4606

Skype: jjjimeneza

George Dilintas

Mar 19, 2021, 6:09:05 AM3/19/21

to material...@googlegroups.com

Diameter is not an essential variable for PQR. Why you torture your self?

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/6e39e586-dc33-4c22-a83e-30255b37a887n%40googlegroups.com.

Dr. Georgios Dilintas,

Dipl. Ing. In Aeronautic and Space Engineering

Ph.D in Mechanics of Solids - Computational Mechanics

A.I.S, A.N.I, IRCA Lead Auditor

Welding, Stress Analysis, Corrosion, QA/QC, Failure Analysis, Risk Analysis

james gerald

Mar 20, 2021, 12:51:44 AM3/20/21

to material...@googlegroups.com

There are certain aspects to be considered in this requirement. Though Plate PQR qualifies for Tube and pipe also irrespective of diameter but the welding process is Automatic orbital GTAW which may require special fixtures for welding Plate or Pipe.

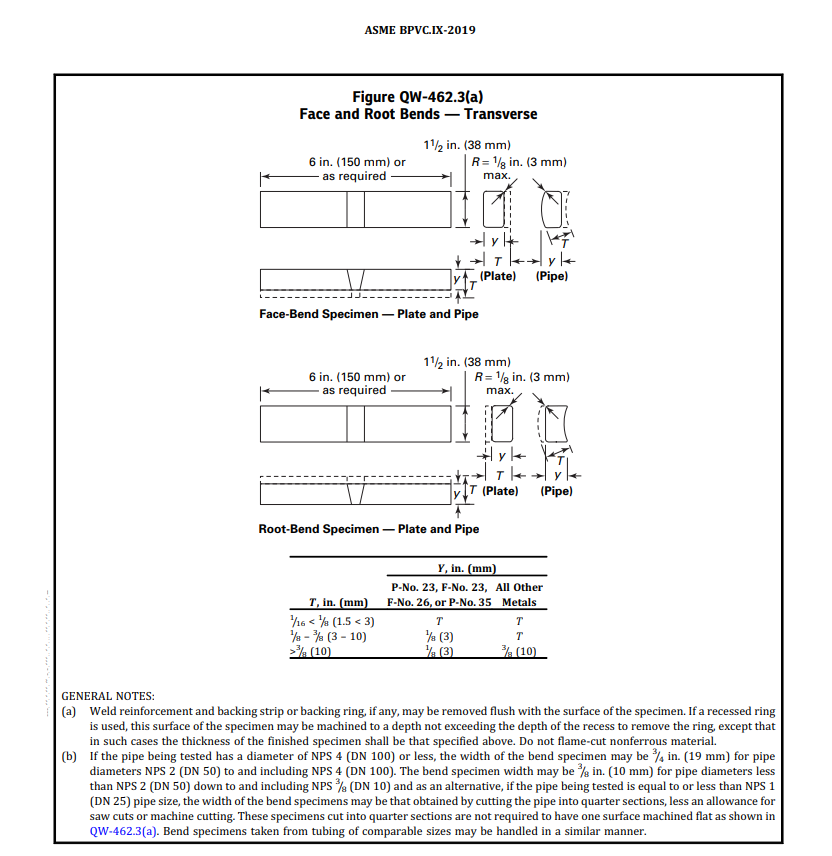

Please find below snap shot of ASME Sec.IX for Transverse Root and Face Bend tests for small diameter tubes.

Please contact a Good Testing Laboratory which may guide you further.

Thanks & Regards

J.Gerald Jayakumar

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAPOi40CfzfiwXorbO-v93Uqkk1u2pv7xyBC5d7FUmZ38ECkuew%40mail.gmail.com.

Vishwas Keskar

Mar 20, 2021, 1:19:00 AM3/20/21

to material...@googlegroups.com

Thanks all ,

Its Customer specific requirements that each Production joint size shall require PQR.

We deployed as a team for test piece preparation . We Cut those small pipes into half sections using hexaw blades in our workshop and then pressed to make these into Flat Strip , We sent these test pieces to lab for further testing.

Face and root bend test set is satisfactory

Have to go extra mile for this. But at the end its happy ending

Vishwas

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAPOi40CfzfiwXorbO-v93Uqkk1u2pv7xyBC5d7FUmZ38ECkuew%40mail.gmail.com.

chandraknat vaidya

Mar 21, 2021, 11:19:14 PM3/21/21

to material...@googlegroups.com

Thats good Vishwas the way is sorted out.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CADder3M4ADzHa8FwfQL9Q8yipznBLpfDy7sjszG%3Dg2vCx55Hfg%40mail.gmail.com.

james gerald

Mar 21, 2021, 11:19:14 PM3/21/21

to material...@googlegroups.com

We did some instrument tubing similar to your application

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CADder3M4ADzHa8FwfQL9Q8yipznBLpfDy7sjszG%3Dg2vCx55Hfg%40mail.gmail.com.

Reply all

Reply to author

Forward

0 new messages