Run-Out Length for SMAW Process

Kurniatullah Sirajudin

Maulik Thakkar

Dear sir,

Recommended run in run out length for base metal thickness;

> 100 mm is min 150 mm

< 100 mm is min 100 mm

Or you can apply simple logic:

Thickness of base metal / each layer height = No of layers * 10-20 mm (staggering length at each layer depending upon the process)

Regards,

Maulik

--

http://www.linkedin.com/groups/MaterialsWelding-122787?home=&gid=122787&trk=anet_ug_hm

The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To post to this group, send email to material...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/bb9ef69c-8c36-42e8-b090-7dd6d32d8af3%40googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

Dindo

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAFK0MUPQLg8Z-Syis6SoFR5WYw2-J2PywoZWNxvjD%3DywtafEtQ%40mail.gmail.com.

prem_nautiyal26

John Henning

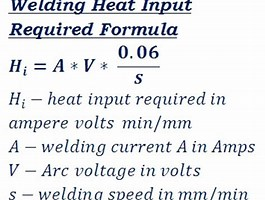

One method of heat input control is often referred to as the “run of the rod” method or the run out length. This method uses the provisions of ASME Section IX QW-409.1(b)(2). Basically, you measure the length of weld and length of SMAW electrode(s) consumed that then is the basis for determining the minimum length of weld that must be deposited per length of electrode burned. See below for Code reference.

Enjoy - John

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/x4wy765uvcnprjyvpuhdiica.1460589900305%40email.android.com.

MUNHOZ Sergio TECHINT

Run-out length is the length of weld deposited from one electrode, usually used to control the heat input .

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/x4wy765uvcnprjyvpuhdiica.1460589900305%40email.android.com.

prem_nautiyal26

Vishwas Keskar Welding Manager Pune India

What is your design calls?

Is impact testing is called in design drawing ?

If yes , qualify WPS with QW 409 supplementary essential variables

Here travel speed is related to run out length

Vishwas Keskar Welding Manager Pune India

> 100 mm is min 150 mm

< 100 mm is min 100 mm

Or you can apply simple logic:

Thickness of base metal / each layer height = No of layers * 10-20 mm (staggering length at each layer depending upon the process)

Dear sir,

Recommended run in run out length for base metal thickness;

> 100 mm is min 150 mm

< 100 mm is min 100 mmOr you can apply simple logic:

Thickness of base metal / each layer height = No of layers * 10-20 mm (staggering length at each layer depending upon the process)

Regards,

Maulik

On Apr 10, 2016 2:25 PM, "Kurniatullah Sirajudin" <kurniatull...@gmail.com> wrote:

Dear Expert,--A week ago, i received comment regarding welding for smaw process.My client ask to me, run-out length for smaw process.I don't know what is run-out length.Please advise meThank you & RegardsKurniatullah Sirajudin

http://www.linkedin.com/groups/MaterialsWelding-122787?home=&gid=122787&trk=anet_ug_hm

The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to material...@googlegroups.com.

james gerald

Thanks & Regards

J.Gerald Jayakumar

> 100 mm is min 150 mm

< 100 mm is min 100 mm

Or you can apply simple logic:

Thickness of base metal / each layer height = No of layers * 10-20 mm (staggering length at each layer depending upon the process)

Dear sir,

Recommended run in run out length for base metal thickness;

> 100 mm is min 150 mm

< 100 mm is min 100 mmOr you can apply simple logic:

Thickness of base metal / each layer height = No of layers * 10-20 mm (staggering length at each layer depending upon the process)

Regards,

Maulik

On Apr 10, 2016 2:25 PM, "Kurniatullah Sirajudin" <kurniatull...@gmail. com> wrote:Dear Expert,--A week ago, i received comment regarding welding for smaw process.My client ask to me, run-out length for smaw process.I don't know what is run-out length.Please advise meThank you & RegardsKurniatullah Sirajudin

http://www.linkedin.com/ groups/MaterialsWelding- 122787?home=&gid=122787&trk= anet_ug_hm

The views expressed/exchnaged in this group are members personel views and meant for educational purposes only, Users must take their own decisions w.r.t. applicable code/standard/contract documents.

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to material...@ googlegroups.com.

To post to this group, send email to material...@ googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/ msgid/materials-welding/ bb9ef69c-8c36-42e8-b090- 7dd6d32d8af3%40googlegroups. com.

For more options, visit https://groups.google.com/d/ optout.

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/e21dba0d-3601-4908-a012-deccee00c495%40googlegroups.com.

George Dilintas

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/e21dba0d-3601-4908-a012-deccee00c495%40googlegroups.com.

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1864291333.3272837.1586791670646%40mail.yahoo.com.

Dindo

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4ePpOTnGYxhLCX8OVoSKNE%2BQCyo57fgm-_-NeqwcdCNBOQ%40mail.gmail.com.

Chris Sabu

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1864291333.3272837.1586791670646%40mail.yahoo.com.

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAGta9%3Dt8KcU-E2a4-LwO7NONBD2tGZmHESYAkcU63b0dWLiMGg%40mail.gmail.com.

Karthik

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAPOi40BJgp%2B2QUSo9aYuKwpdZfm-4QkPOWyvYp2jWmkH_eE2%3DQ%40mail.gmail.com.

harenath jha

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAGta9%3Dt8KcU-E2a4-LwO7NONBD2tGZmHESYAkcU63b0dWLiMGg%40mail.gmail.com.

Dindo

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAPRS9UOarJYCW3W_ueJBCNt3Ec5x2oXroKdk8iwDTLt89GtfKA%40mail.gmail.com.

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAGta9%3DsjF-SDt8YW0_Evjw%3DmVqBp-jf%3DbOsPCrYWQn8at2BmoQ%40mail.gmail.com.

harenath jha

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4eMWcYeGxo6LkTZ8jpG%3DwRjcjfAOkbrhLz6NoEKcNcG18Q%40mail.gmail.com.

Dindo

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4eMWcYeGxo6LkTZ8jpG%3DwRjcjfAOkbrhLz6NoEKcNcG18Q%40mail.gmail.com.

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAPRS9UNedgYbkQZLcWPrnTpxwoX%2Bf3BeMwhzjEpnkrSahU_KUQ%40mail.gmail.com.

Regino Millan

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/e21dba0d-3601-4908-a012-deccee00c495%40googlegroups.com.

Regino millan