QW 200.4: Combination of Welding Procedures

Sudhakar Kuppuswamy

Hi,

Currently

one of my clients is having an ambiguity in applying the requirements of ASME

Section 09 Clause QW 200.4: Combination of Welding Procedures, Subclause:

a & b requirements. Hence, support is required in finding an interpretation

from ASME Section 09. (Interpretation in CS connect is not apparent for this clause)

Background: Two PQRs were qualified separately, PQR A is qualified with SAW process using 8 mm thickness plate and PQR B is qualified with SMAW process using 8 mm thickness plate.

Question: While combining the two PQRs to weld a plate with thickness(es) ranging from 1.5 mm to 16 mm.

Do as per QW 200.4, it is necessary to have the root pass process PQR need to be qualified on a minimum 13 mm thickness plate?

I’m pretty sure it is not required to have a root pass process PQR with minimum 13 mm thickness in the above case. However, it would be helpful if you found any interpretation on this.

james gerald

Thanks & Regards

J.Gerald Jayakumar

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CABF8NYVXu5Nu5k5yKnxevQH8xhLhEqjw0Fw7z0ogm--MNr-F-A%40mail.gmail.com.

james gerald

Thanks & Regards

J.Gerald Jayakumar

Kannayeram Gnanapandithan

--

james gerald

Thanks & Regards

J.Gerald Jayakumar

Sudhakar Kuppuswamy

Base metal: 1.5 to 16 mmSMAW weld metal: 16 mm maximumSAW weld metal: 16 mm maximum.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4eP7avyONq_9LgO-jHnv-pdG4hwLPuLC-w2q6Kf0ccJHHQ%40mail.gmail.com.

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CABF8NYWUtqww3C-Td%2BnmyG3WC1M78s00tWp2NzJOUveX4TEaTg%40mail.gmail.com.

Sourav Bohrays

--

Sudhakar Kuppuswamy

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4ePudg57W0CdZtK52Vd%3DKoQaz2jb%3DR0V1jW%3DHg62kz-i5g%40mail.gmail.com.

james gerald

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CABF8NYX3hrDGy_qpEymA0yBH1xThF6oyHPuLcA-wfGz29EtdqQ%40mail.gmail.com.

pgos...@rogers.com

Hello, Sudhakar,

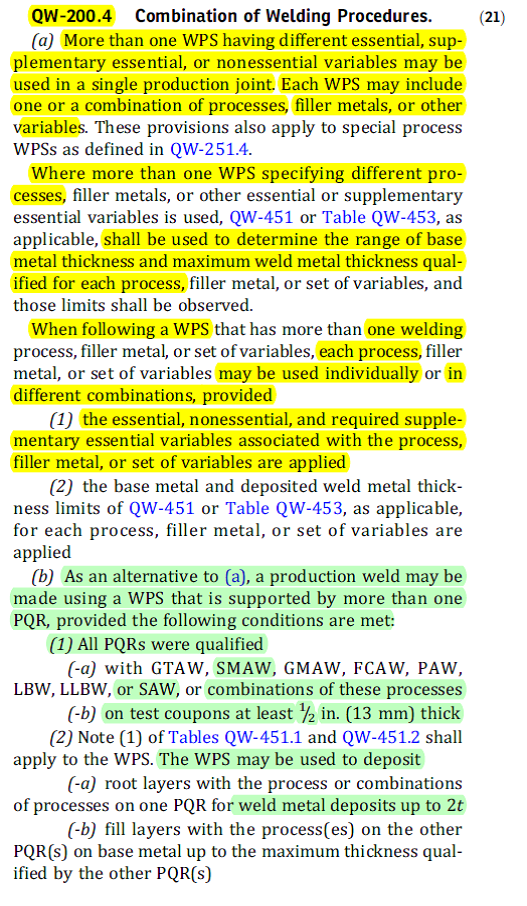

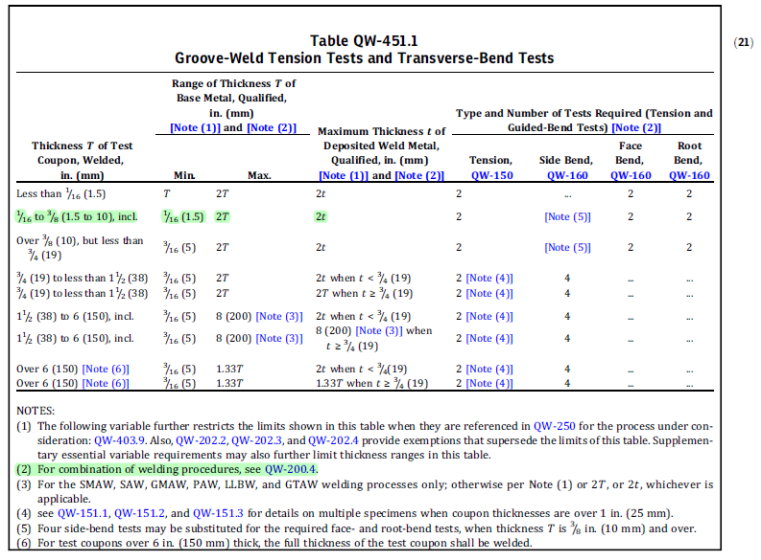

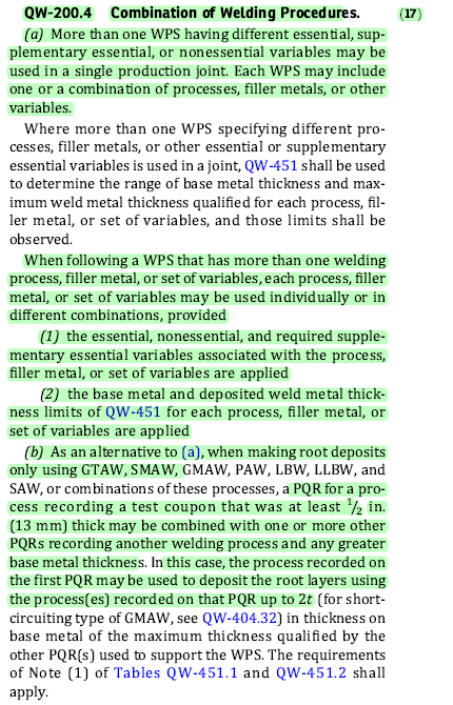

Please see the clause QW-200.4 from 2017 & 2021 editions of Sec-IX. You may exercise the options of paragraph (a) or paragraph t (b) as indicated below. The wordings are slightly different in 2017 & 2021 versions.

In my opinion you may still use the PQR’s as described below. If you read the texts indicated between the 2 arrows as below, a combination of the qualified PQRs may be used to write a WPS of SMAW+SAW. You need to refer the table QW-451.1 to justify the qualified thickness for both base & weld metal for each qualified process.

Note: The steps indicated paragraph (b) is an alternative to paragraph (a).

Thanks.

Pradip Goswami.P.Eng, IWE.

Independent Consulting Welding & Metallurgical Engineering Specialist

Saudi Aramco Approved Designated Project Welding Engineer (DPWR)

Qatar Petroleum Approved, SME-Materials & Corrosion Engineering.

Linkedin: https://www.linkedin.com/in/pradip-goswami-2999855/

Email:pgos...@rogers.com,pradip....@gmail.com

Cell/Whasapp:1-905-9793232

Sec IX-2021.

Sec IX-2017

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CABF8NYVXu5Nu5k5yKnxevQH8xhLhEqjw0Fw7z0ogm--MNr-F-A%40mail.gmail.com.

Mohd Siraj

Sudhakar Kuppuswamy

There are benefits! What if there are large tank job and one need to weld the roof joint butt welds, where back chipping is required. we can effectively weld root pass with SMAW & further passes with SAW. Good productively can be made.

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/5773e14a-e4c7-4c2c-8138-cf9ea43dcc05n%40googlegroups.com.

Raghul

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CABF8NYV5JvRA9jLVDZND1L-Qkc%2BOGDZYzJdSJP7APcH8WArNcA%40mail.gmail.com.

Mohd Siraj

lawrenced...@gmail.com

Standard Designation:

BPV Section IX

Edition/Addenda:

Para./Fig./Table No:

Subject Description:

Section IX, QW-200.4(b), Combination of Welding Procedures

Date Issued:

09/22/1993

Record Number:

BC93-490

Interpretation Number :

IX-92-75

Question(s) and Reply(ies):

- Question: When writing multi-process welding procedures per QW-200.4(a), where the tube wall thickness is less than 1 in., using a separate qualification for the root deposit only, must the root deposit qualification coupon be 1/2 in. minimum thickness as stated in QW-200.4(b)?

Reply: No.