Applicability of Impact requirement as per ASME B31.3

vinit vani

Dear All,

Design code – ASME B31.3, Welding Code- ASME BPVC SEC IX

Material to be used used during Fabrication - SA 333Gr6 (P No.1 Gr. 1) To SA 350-LF2 (P No.1 Gr. 2)

Amol Betkar

Dear Vinit,

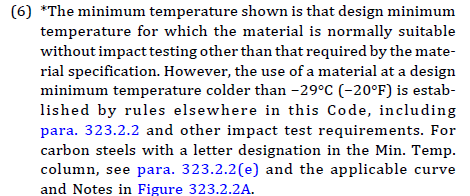

For the applicability of PQR impact requirements based on the provided details, we need to refer to the ASME Boiler and Pressure Vessel Code (BPVC) Section IX, which covers welding qualifications.

Since you're dealing with welding and materials in the context of ASME BPVC Section IX, the specific clause relevant to your scenario would be Clause QW-402.2. This clause outlines the impact test requirements for procedure qualification.

Based on the information provided:

- Material: SA 333Gr6 (P No.1 Gr. 1) to SA 350-LF2 (P No.1 Gr. 2)

- Thickness range: 5.54mm (Minimum) - 9.53mm (Maximum)

- PWHT: Nil

- MDMT: -45 Deg Cel.

Given these details, you would need to assess if impact testing is required for the welding procedure qualification. The decision would depend on factors such as the material specification, thickness, service conditions, and design requirements.

According to ASME BPVC Section IX, if the design temperature is equal to or colder than the Minimum Design Metal Temperature (MDMT) of the material, impact testing may be required. In your case, the MDMT is -45 Deg Cel., and since the design temperature is not mentioned, it's essential to evaluate whether it's equal to or colder than -45 Deg Cel.

Furthermore, Clause QW-403.6 provides exemptions from impact testing for certain materials, thicknesses, and service conditions. It's crucial to review this clause to see if any exemptions apply to your specific scenario.

Ultimately, the applicability of PQR impact requirements would depend on a detailed assessment of the specific welding procedure, material properties, thicknesses, and design conditions, in accordance with the ASME BPVC Section IX.

Regards,

Amol K.Betkar

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/670487658.2039399.1713956840743%40mail.yahoo.com.

thulaib arakkal