A335P11 material - Delayed PWHT condition

321 views

Skip to first unread message

PARAI Reaction Channel

Nov 7, 2019, 10:19:04 PM11/7/19

to material...@googlegroups.com

Dear Experts,

For one of our project,

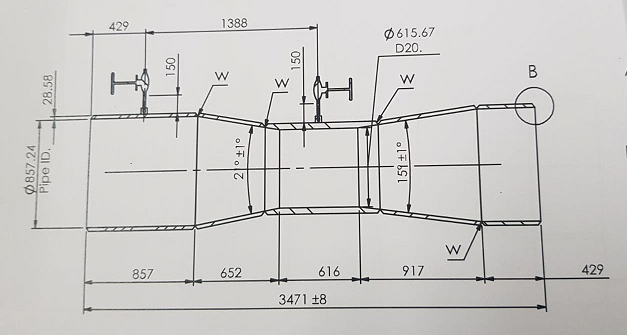

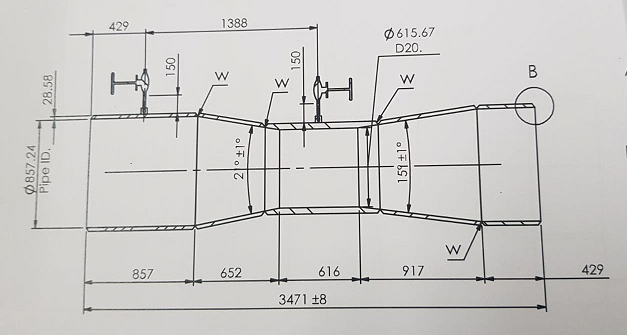

With reference to the sketch shown below, we are going to weld 4 number of Single V Butt joints for A335P11 to itself ( P No. 4 ), pipe Thk of max 28.6 mm by using GTAW & FCAW process ,

Preheat Tempr. of Min. 120 Deg C ( Plan to use Burner ) and PWHT from 650 to 707 Deg C as per ASME B31.3 code.

After we complete the welding in our shop and bring back to the normal ambient tempr. around 15 Deg C, can we do PWHT after 1 or 2 days gap and then we do RT and PT ?

I worry that, during winter in Korea, the ambient tempr. may drop to Minus 10 Deg C.

As there is no weld spec from client for P No.4 , can we do PWHT after 2 days gap.

Please suggest me with any weld instructions for P. No.4 , Preheat maintenance, in order to avoid any crack after welding and with delayed PWHT condition.

With best regards,

Saravanan.Sornam,

Korea

anand gupta

Nov 8, 2019, 2:41:20 AM11/8/19

to material...@googlegroups.com

Dear

Where is written that after welding immediate do PWHT.

you can do PWHT after one, two or more days.

We r doing preheat during welding and after welding complete, we have continue preheat and come down temp upto ATM.

Regards

A p gupta

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CALV1rkKyaKN%2BXoGTzSC7ok%3DnYVeUwbp1CYp-YyEJn2CYFrvebg%40mail.gmail.com.

Karthik

Nov 8, 2019, 3:05:49 AM11/8/19

to material...@googlegroups.com

Hi,

For welds made by SMAW and FCAW, after completion of welding and without allowing the weldment

to cool below the minimum preheat temperature, the temperature of the weldment shall be raised to a

temperature of ATLEAST TO MAXIMUM INTERPASS TEMPERATURE MAINTAINEDAS A MINIMUM OR 300-350 DEGREE CELSIUS for a minimum period of two hours. This hydrogen bake-out

treatment may be omitted provided the electrode used is classified by the filler metal manufacturer with a

diffusible-hydrogen designator of H4 (e.g., E7018-H4);

--

Rajnish Dixit

Nov 10, 2019, 3:26:13 AM11/10/19

to material...@googlegroups.com

Dear Saravanan,

As per good engineering practices, 48 hours gap is suffecient time for P11material after PWHT as per your mail. More over, please consult your client if they have any specific recommendation.

Also, please go with the attached piece of information found on net, may be useful for you.

Thanks & Best Regards,

Rajnish

As per good engineering practices, 48 hours gap is suffecient time for P11material after PWHT as per your mail. More over, please consult your client if they have any specific recommendation.

Also, please go with the attached piece of information found on net, may be useful for you.

Thanks & Best Regards,

Rajnish

--

Kannayeram Gnanapandithan

Nov 10, 2019, 10:16:19 PM11/10/19

to materials-welding

U can. Since it is bainatic structure, hardness level may not be as high as in Martensite structure. Why do you want delay in doing PWHT, if NDE is delayed, it is a reasonable one after PWHT because of delayed crack

--

PARAI Reaction Channel

Nov 10, 2019, 10:16:19 PM11/10/19

to material...@googlegroups.com

Dears,

Regards,

thanks for the reply.

We are going to use GTAW & FCAW for P No. 11 materials up to 28 mm Thk, so can we bake for 300 to 350 Deg C for an Hr and bring back the Tempr. to 15 Deg C.

Can we do PWHT after 1 day Or to start PWHT immediately after baking .

RT will be taken after 48 Hrs of welding completion time.

If you have any weld spec for P11 materials, then please share me.

Regards,

Saravanan,

Korea

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/462633344.1307021.1573352576393%40mail.yahoo.com.

VENKATA BALARAM

Nov 10, 2019, 10:16:20 PM11/10/19

to material...@googlegroups.com

Noted your query,there is no hard & fastened rule in the code for when to start PWHT after welding.In your case only pre heat & post heat is mentioned.Dont forget to maintain

Interpass temparatue for these P4/P11 matallurgies.

.

However to carryout RT or any NDTs in low ambent temperatures or lower service temperatures,it is preferably after 48hrs. of welding as per good engg. practice.

Check the project spec. for BSR-RT & ASR-RT and comply the same.Check the the hardness of weldments,HAZ and parent metal before & after PWHT.

Regards

IVB

--

Kannayeram Gnanapandithan

Nov 10, 2019, 10:30:57 PM11/10/19

to materials-welding

Not only 48hrs and welding, NDE should be after SR because there is lot of chance for Reheat cracking

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CALV1rkLeAjVpqjXNdE3LE_%2BihC_jywh1mtEaCCb7A0kubj0cUQ%40mail.gmail.com.

PARAI Reaction Channel

Nov 18, 2019, 6:15:31 AM11/18/19

to material...@googlegroups.com

Dear Mr.Kannayeram,

Thank you.

We are going to use GTAW & FCAW combination for it. After welding complete for the 6 Set. of A335 P11 Pipes as per the previously sent sketch, we are planning to do PWHT, either by local method or at Subcontractor's heat treatment area , all together in one time.

So, it may take Min. 1 day gap for PWHT preparation, after the completion of welding.

Also, if you have any spec for Preheat maintenance, its control and PWHT requirements for A335 P11 materials, then please send me a copy.

Regards,

Saravanan,

Korea

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4eOZgJ0CNMJ4kFbBEv%2BSyVUryKOOy_CdqhngBQfzw2w1Cw%40mail.gmail.com.

sunil kaushik

Nov 19, 2019, 12:29:32 AM11/19/19

to material...@googlegroups.com

You can go for post heat if there is a minus temperature.

--

chandraknat vaidya

Dec 22, 2019, 3:43:53 AM12/22/19

to material...@googlegroups.com

Yes Karthik is right.

After completion of Hydrogen Bake out/ De Hydrogenation there willnot be any problem for delay in PWHT.

Vaidya CL

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/802611431.889671.1573200255070%40mail.yahoo.com.

Reply all

Reply to author

Forward

0 new messages