Fwd: WPS TO QUALIFY THE OF THE WELDER

Rene Alvarado

FE DE ERRATAS

Can I use a WPS qualified with the SMAW process in position 6G on pipes Copper Nickel to Carbon Steel with a thickness of 0.237” and with backing ring to qualify the skill of the welder in fillet welding with the SMAW process in position 5F on pipes Copper Nickel ( O.D. 2 ½” thickness 0.280”) to Carbon Steel (O.D. 3” schedule 160 in accordance ASME IX?

Thanks

De: Rene Alvarado <rene.alvar...@gmail.com>

Date: jue, 31 mar 2022 a la(s) 08:40

Subject: WPS TO QUALIFY THE OF THE WELDER

To: <material...@googlegroups.com>

Experts

Can I use a WPS qualified with the SMAW process in position 6G on pipes Copper Nickel to Carbon Steel with a thickness of 0.237” and with backing ring to qualify the skill of the welder in fillet welding with the SMAW process in position 6G on pipes Copper Nickel to Carbon Steel with a thickness of 0.125” ?

Thanks

Rene Alvarado

Karthik

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit

Rene Alvarado

Thanks Karthik but I'm sorry because the wording of my question was wrong.

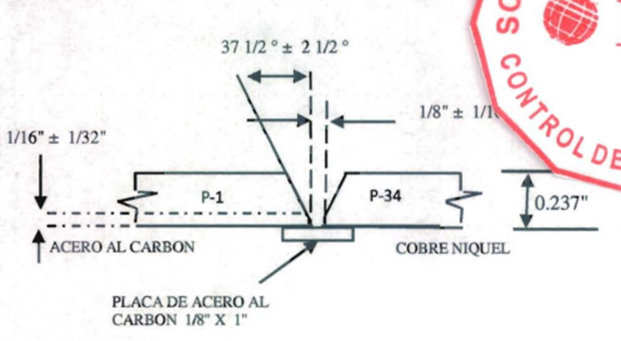

Our WPS-XXX was qualified in 2012 = SMAW / Manual / P·No.: 1 Group No 1 y 2 a P-No: 34 Group No. N/A with 0.237” thickness in position 6G (SA-106 Gr. B to SB-466 ALLOY 706) with backing ring (SA-36) / Filler metal E-NiCu-7 of 3/32” and 1/8” / minimum preheat temperature 400° F and interpass temperature 600° F.

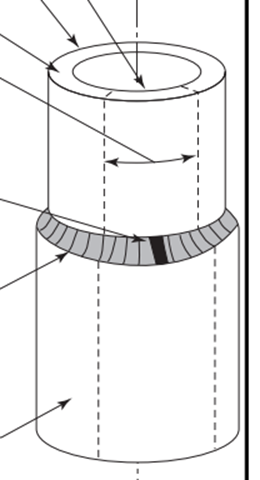

Nowadays in the year 2022 we need to qualify a welder in fillet welding according to the Figure QW-462.4(c) pipe to pipe of ASME IX using the WPS-XXX described above.

Question: Can we use the WPS-XXX to qualify the welder in fillet welding according to the Figure QW-462.4(c) pipe to pipe of ASME IX?

Thank very much

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/2055448215.352808.1648795241955%40mail.yahoo.com.

Karthik

Rene Alvarado

Thanks for your technical advice Karthikeyan. S.

Again I have made a mistake in my question.

1. The performance qualification test shall be welded in accordance with qualified Welding Procedure Specifications (WPS), or Standard Welding Procedure Specifications(SWPS).

2. We have a procedure classified ten years ago (see figure below) WPS-XXX and we used the process SMAW (manual); materials P·No.: 1 Group No 1 y 2 a P-No: 34 Group No. N/A with 0.237” thickness in position 6G (SA-106 Gr. B to SB-466 ALLOY 706) with backing ring (SA-36) and Filler metal E-NiCu-7 of 3/32” and 1/8”.

3. Today we need to qualify the skill of a welder in according to Figure QW-462.4(c) Fillet Welds in Pipe-Performance using the same materials P•No.1 Group 1 y 2 a P-No: 34 Group N/A (SA-106 Gr. B to SB-466 ALLOY 706); the process SMAW (manual) and Filler metal E-NiCu-7 of 3/32” or 1/8”.

Question. Can we use the WPS-XXX indicated in item 2 to qualify the skill of the welder?

Regards

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1861318586.1026498.1649143651725%40mail.yahoo.com.

james gerald

J.Gerald Jayakumar

Karthik

Rene Alvarado

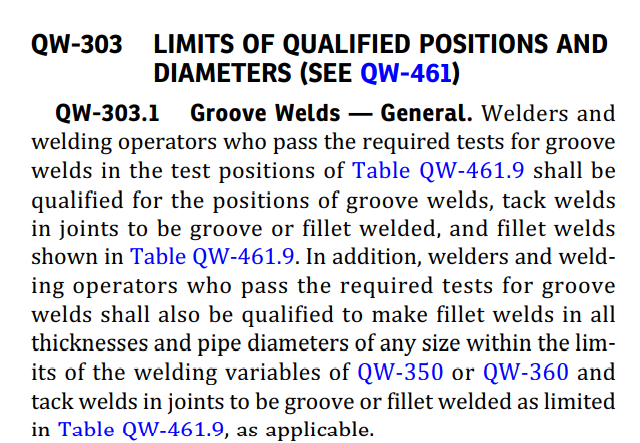

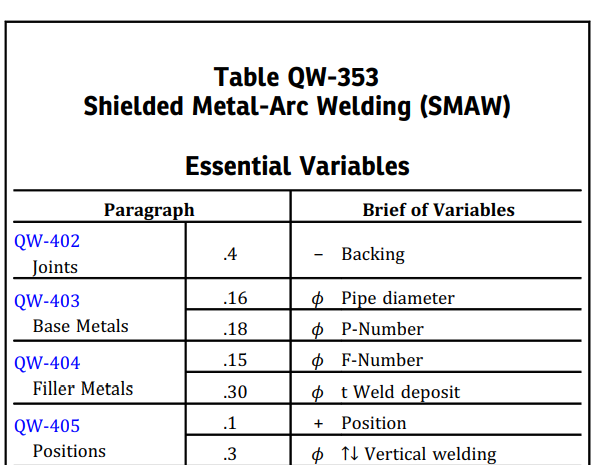

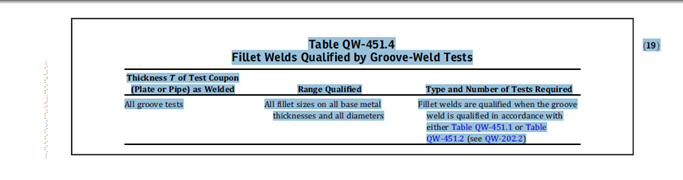

Therefore we can qualify the skill of a welder in position 5F (fillet), SMAW process, P-1 to P-34, filler metal E-NiCu-7 USING a Welding Groove With Backing (WPS) with the same SMAW process, same material. P-1 to P-34, same filler metal E-NiCu-7

Regards

FYIQW-310.2 Welding Groove With Backing. The dimensions of the welding groove on the test coupon used in making qualification tests for double‐welded groove welds or single‐welded groove welds with backing shall be the same as those for any Welding Procedure Specification (WPS) qualified by the organization, or shall be as shown in Figure QW-469.1. A single‐welded groove‐weld test coupon with backing or a double‐welded groove‐weld test coupon shall be considered welding with backing. Partial penetration groove welds and fillet welds are considered welding with backing.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/31687472.1503576.1649312075535%40mail.yahoo.com.

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAHbC_j2qhEUVzuR_vb%3DYwP3_cG0hUe80-nPpJ%2BKektr3VYBFnA%40mail.gmail.com.

Rene Alvarado

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/31687472.1503576.1649312075535%40mail.yahoo.com.

james gerald

Kannayeram Gnanapandithan

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/922129478.1710383.1649388452846%40mail.yahoo.com.

prasad loke

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAHbC_j0AokN3QNG6ZBopCKcAgR1cvLoe5RPPdh%2BvfLY1tqyX_A%40mail.gmail.com.

james gerald

Thanks & Regards

J.Gerald Jayakumar