HEAT EXCHANGER CONSTRUCTION

157 Aufrufe

Direkt zur ersten ungelesenen Nachricht

Vishwas Keskar Welding Manager WELDING

06.10.2022, 00:22:1106.10.22

an Materials & Welding

Dear Experts

One of HEX involves following MOCs -

HEX tubes - SA 789 TYP 32205

Tubesheet -SA 266 CL 2 CS - Tube sheet IS cladded with TYP S32205 overlay.

Shell side - CS -SA 516 GR 70 - 75mm thk

Channel side - CS- SA 516 GR 70 - 75 mm thk

PWHT is required for Tube sheet to Shell welding and Tube sheet to Channel welding. These are butt welds with CS Weld metal .

PWHT is not required for Tube sheet to HEX Tube welding due to DSS tube to DSS cladding.

Pl advice for the care that shall be taken during PWHT of Tube sheet to Shell welding and Tube sheet to Channel welding.

Thanks and regards

Vishwas - IWE

International Welding Engineer

Raghuram Bathula

06.10.2022, 00:30:0306.10.22

an material...@googlegroups.com

Does the tube sheet have a lip? Please share a sketch at the weld location? practically it is difficult to avoid heat exposure to duplex clad? you need to change clad material, check with your process metallurgist

Prabhu kumar Loganathan

06.10.2022, 23:28:0706.10.22

an material...@googlegroups.com

Hi,

In general, DSS weld overlay is not recommended in CS due to cracking and other weldability issues. Moreover, Tube sheet forging with heavy weld overlay requires stress relieving too.

However, stress relieving is not recommended for DSS, Hence in my opinion DSS weld overlay on TS to be replaced with Alloy 625 weld overlay wherein all these these issues related to weldability & PWHT will be solved.

Regards,

Prabhu.--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/a163c4a4-fe95-4245...@googlegroups.com.

In general, DSS weld overlay is not recommended in CS due to cracking and other weldability issues. Moreover, Tube sheet forging with heavy weld overlay requires stress relieving too.

However, stress relieving is not recommended for DSS, Hence in my opinion DSS weld overlay on TS to be replaced with Alloy 625 weld overlay wherein all these these issues related to weldability & PWHT will be solved.

Regards,

Prabhu.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/a163c4a4-fe95-4245...@googlegroups.com.

Vishwas Keskar Welding Manager WELDING

06.10.2022, 23:28:3406.10.22

an Materials & Welding

I too concerned about DSS cladding including DSS HEX tubes .

Is it ?

Vishwas

james gerald

09.10.2022, 23:25:3509.10.22

an 'Prabhu kumar Loganathan' via Materials & Welding

Nice to see you back Prabhu.

If service restrictions are only due to chloride concentration then we try the SASS like 904L, 254 SMO & 654 SMO/

Your views

Thanks & Regards

J.Gerald Jayakumar

Prabhu kumar Loganathan

10.10.2022, 01:29:5410.10.22

an material...@googlegroups.com

Hello Gerald,

Yes, below specified Super ASS is an alternate to DSS due to high Cl environment, however market availability is very less which leads to long delivery time and hence suggested to go for Inconel 825 or 625, again Alloy 825 weld deposition is having cracking issues >5mm thick which is not recommended.

Regards,

L. Prabhu kumar

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1533605827.35179...@mail.yahoo.com.

Yes, below specified Super ASS is an alternate to DSS due to high Cl environment, however market availability is very less which leads to long delivery time and hence suggested to go for Inconel 825 or 625, again Alloy 825 weld deposition is having cracking issues >5mm thick which is not recommended.

Regards,

L. Prabhu kumar

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

james gerald

10.10.2022, 02:08:5810.10.22

an 'Prabhu kumar Loganathan' via Materials & Welding

Thanks Prabhu.

Is SCC in chloride environment a problem with SASS & 625.

Moreover SASS are available mostly in European market.

Thanks & Regards

J.Gerald Jayakumar

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1665372339.S.23528.2356.f5-224-164.1665379709.28493%40webmail.rediffmail.com.

Vishwas Keskar Welding Manager WELDING

10.10.2022, 04:56:0210.10.22

an Materials & Welding

Pl. note that all the HEX Tubes are also of DSS TYP S32205 .

So the concerned is for these DSS tubes also.

james gerald

10.10.2022, 23:24:4310.10.22

an material...@googlegroups.com

sorry for being out of track.

I believe the welding between Tube sheet and Shell/Channel via a LIP provided in the TS forging where you can excercise a control.

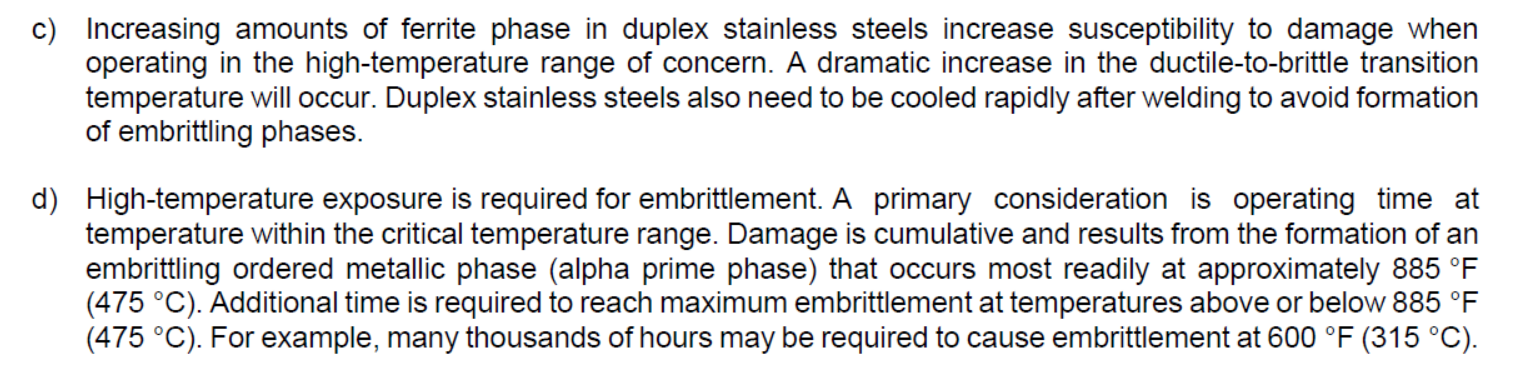

Ensure DSS is not exposed to temperature greater than 400 degC to avoid 475 embrittlement (alpha prime intermetallic)

Thanks & Regards

J.Gerald Jayakumar

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/6a3b7d65-5836-4f67-abfa-b24b6e88551an%40googlegroups.com.

Prabhu kumar Loganathan

10.10.2022, 23:24:5210.10.22

an material...@googlegroups.com

Hi Vishwas,

Yes, Tube also to be changed to Alloy 825 and TS to be overlay with Alloy 625 (ENiCrMo-3) with PWHT.

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/6a3b7d65-5836-4f67...@googlegroups.com.

Yes, Tube also to be changed to Alloy 825 and TS to be overlay with Alloy 625 (ENiCrMo-3) with PWHT.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1665372339.S.23528.2356.f...@webmail.rediffmail.com.

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

james gerald

11.10.2022, 01:49:2311.10.22

an 'james gerald' via Materials & Welding

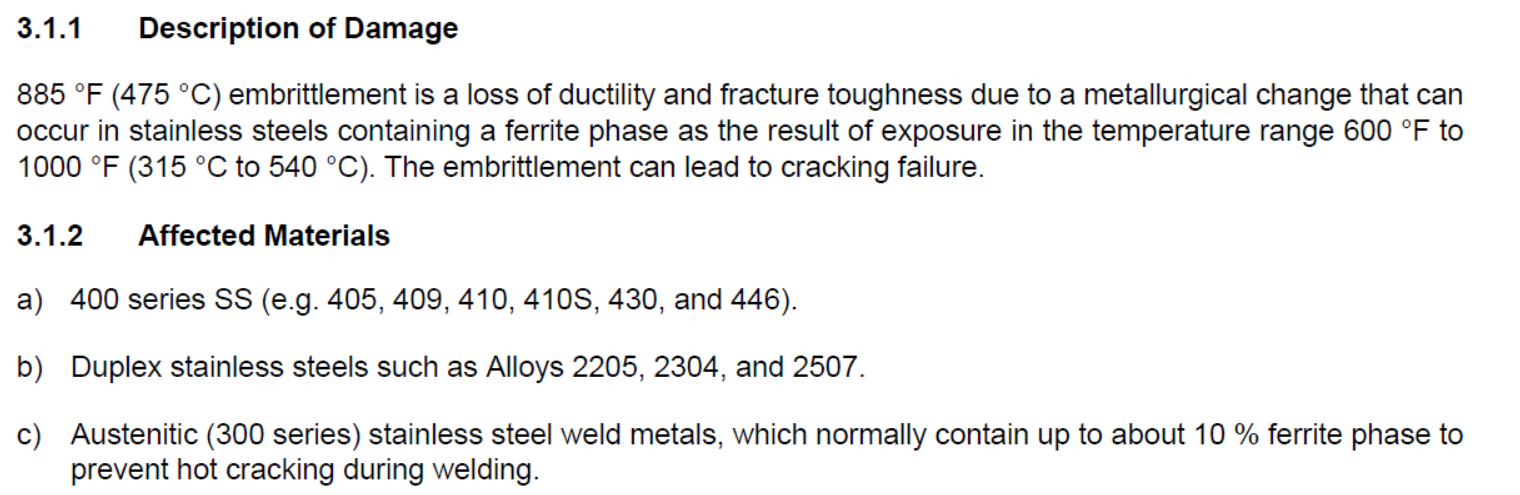

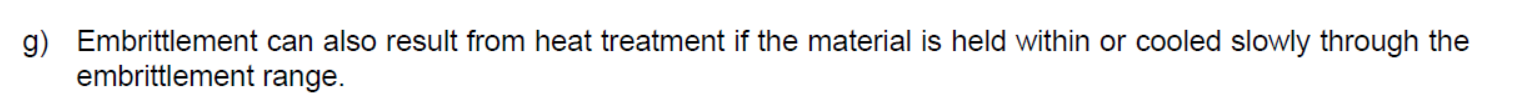

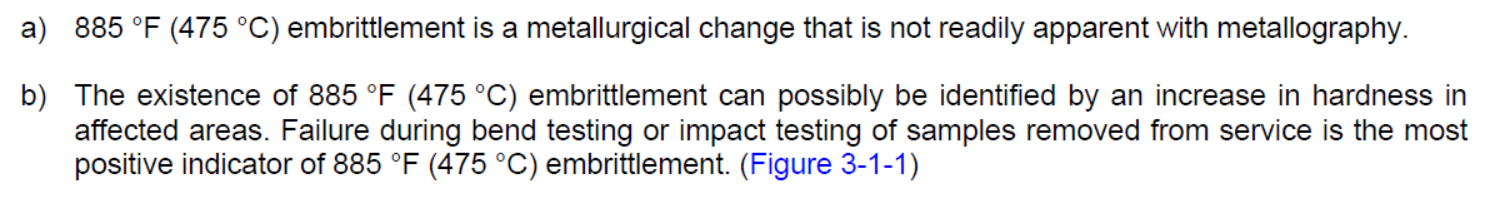

Just some info on 475degC embrittlement.

Thanks & Regards

J.Gerald Jayakumar

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1461398998.3824451.1665405226943%40mail.yahoo.com.

Vishwas Keskar Welding Manager WELDING

12.10.2022, 23:22:3112.10.22

an Materials & Welding

Thanks a lot !!

What is recommended distance of Lip that is required for avoiding the exposure of heat ?

james gerald

13.10.2022, 00:22:0113.10.22

an material...@googlegroups.com

Normally I have seen LIP provided for Nozzle to shell welding to obtain 100% RT. But one of our vendor sometime back has proposed and so you discuss with your Design Engineer.

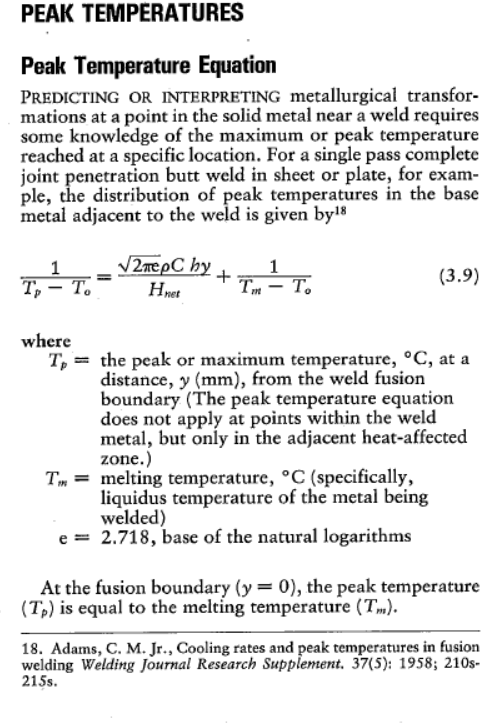

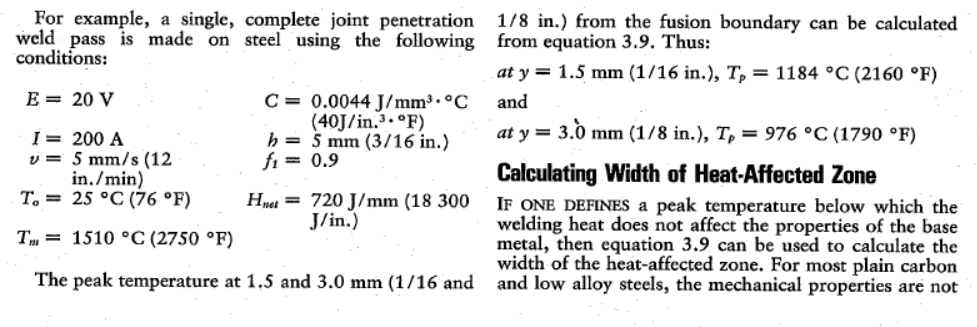

In AWS Handbook, vol.1,chapter 3 Heat Flow in welding have distance vs Peak Temperature calculation (Snap shot provided below) based on the same calculate for Tp of 400degC in DSS.

Thanks & Regards

J.Gerald Jayakumar

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/0629ef61-dbe4-4ad6-9cb7-dd4e5c67d798n%40googlegroups.com.

Vishwas Keskar Welding Manager WELDING

13.10.2022, 05:50:2413.10.22

an Materials & Welding

Thanks

Pl help to inform the name of the book /literature from where the below snap is taken

Thanks and regards

Vishwas

james gerald

13.10.2022, 07:05:4213.10.22

an material...@googlegroups.com

API 571 Damage Mechanisms

Thanks & Regards

J.Gerald Jayakumar

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/da57bdef-0903-4496-823b-dbed31173e06n%40googlegroups.com.

Vishwas Keskar Welding Manager WELDING

01.12.2022, 06:15:0401.12.22

an Materials & Welding

Can anybody help for Lip Length that is to be planned in the tube sheet so that during PWHT of Tube sheet to Channel and Tube sheet to Shell , the DSS TYP 32205 weld over lay and DSS TYP 32205 Tubes will not get exposed to temperature of 400 Deg C or more .?

Thanks

Vishwas - IWE

International Welding Engineer

anthony chundal

01.12.2022, 06:41:3501.12.22

an material...@googlegroups.com

Hi,

You have provide lip of 40mm,

Make sure you pull the tubes back while heat treatment,

Kind Regards

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/117461b9-ea16-4f52-b5b6-3a7c905c9364n%40googlegroups.com.

Vishwas Keskar Welding Manager WELDING

10.12.2022, 01:51:2210.12.22

an Materials & Welding

One of thought is Nitrogen Purging in the HEX tubes during PWHT of Shell to Tube sheet , Tube sheet to Channel joints

Can any one throw light on Nitrogen purging system and its effectiveness ?How it is done / system in market ?

This will keep DSS HEX tubes cool (< 300 Deg C) and serve the purpose

Thanks and regards

Vishwas - IWE

International Welding Engineer

Kannayeram Gnanapandithan

10.12.2022, 03:57:2010.12.22

an materials-welding

better argon. nitrogen will react with material beyond 450 degcel

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/0c84649c-3ab4-4aca-a1ed-26c846765654n%40googlegroups.com.

Allen antworten

Antwort an Autor

Weiterleiten

0 neue Nachrichten