Weldability of A283 Gr C with A573 Gr70

61 views

Skip to first unread message

Benaouda Mezrar

Jan 25, 2023, 11:32:19 PM1/25/23

to Materials & Welding

Dear friend

could anyone answer my question, the question is : could we weld A573 GR70 with A283GR C

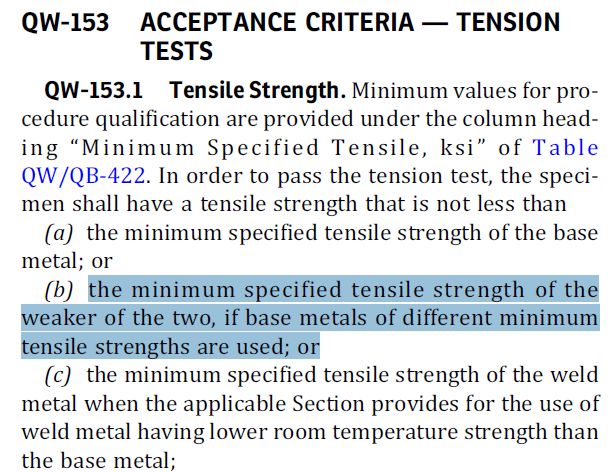

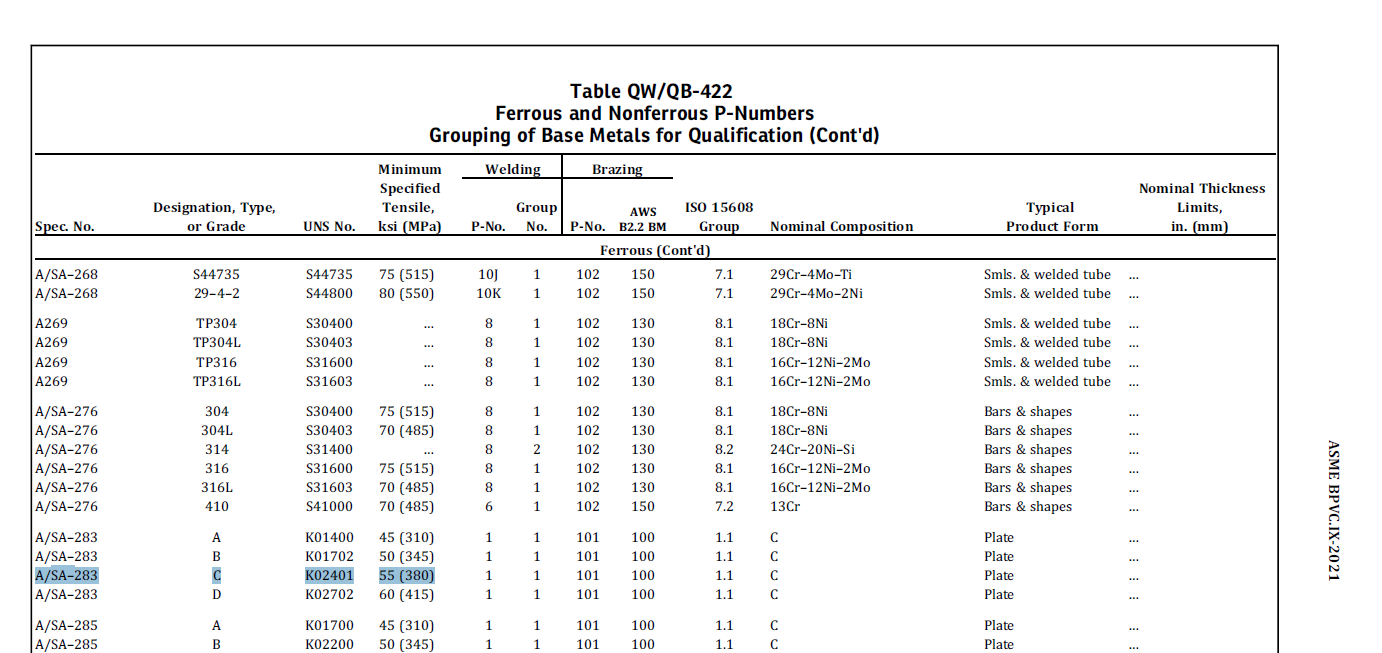

In my opinion we can't weld them because the minimum specified tensile are

for A283 GR C = 380 MPA

for A573 Gr70 = 485 MPA

Please friend help me i need this information emergency

if the answer is yes which type of filler metal we should use for SMAW

james gerald

Jan 26, 2023, 1:40:15 AM1/26/23

to material...@googlegroups.com

Use E7018 / E7018-1

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/20e0e61e-9ee4-4ef3-9080-fe83ae9c39ban%40googlegroups.com.

Benaouda Mezrar

Jan 26, 2023, 4:12:21 AM1/26/23

to material...@googlegroups.com

But sir we use these two nuances for construction of storage tanks. Is it applicable ? with different thickness

sir please could you give me more arguments about the weldability of these two nuances ?

thank you a lot for your helps sir

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/2043007948.1323331.1674715164817%40mail.yahoo.com.

james gerald

Jan 26, 2023, 4:24:13 AM1/26/23

to material...@googlegroups.com

What is the design CODE API 620 / 650

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CANKYR7tUR_QCCPS-j8BRPq7tPAhjZqh2fD-kYKc72h%2BB_2Z0RQ%40mail.gmail.com.

Benaouda Mezrar

Jan 26, 2023, 11:21:39 PM1/26/23

to material...@googlegroups.com

API 650

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/289735639.1335750.1674725002198%40mail.yahoo.com.

james gerald

Jan 26, 2023, 11:21:41 PM1/26/23

to material...@googlegroups.com

Benaouda Mezrar

Jan 27, 2023, 3:05:38 AM1/27/23

to material...@googlegroups.com

A573 gr 70 12mm

A283 gr C 10mm

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/1487907621.1327855.1674725111818%40mail.yahoo.com.

james gerald

Jan 28, 2023, 12:41:07 AM1/28/23

to material...@googlegroups.com

There are certain factors to be considered while selecting the welding consumable.

1. The Tensile strength of the welding consumable shall be higher than the minimum specified Tensile strength of the Base material.

2. If two different grades are welded the welding consumable tensile strength shall be higher than the lowest grade.

3. If it is a structural weld and welding to the pressure boundary then low H2 electrode is preferred such as E7018 / E7108-1.

4. If it is between a non pressure part to non-pressure part then you can prefer E6013 for your requirement and thickness.

5. If the Thickness(>25mm) & Carbon equivalent is higher it is preferred to weld with a low H2 electrode such as E7018

Thanks & Regards

J.Gerald Jayakumar

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CANKYR7tJdhQOR4aud6MWGqznhh7E7UTYQi0jwC%3DK54yBjOk2vg%40mail.gmail.com.

Reply all

Reply to author

Forward

0 new messages