interruption limitations to stop welding

233 views

Skip to first unread message

sankar krishnan

Apr 1, 2021, 2:51:58 AM4/1/21

to Materials & Welding

Dear All ,

In our Pressure vessel project 10mm thickness plate they using (GTAW+SAW) process , They have welded GTAW with 4 mm of 10mm thickness and leave open for 1 days .. I like to Know what is the interruption limitations to stop welding Limits for <19mm thickness

Please send me code documents

Vishwas Keskar

Apr 1, 2021, 3:59:21 AM4/1/21

to material...@googlegroups.com

what is the material being welded "

CS ,Cr Mo or SS

--

https://materials-welding.blogspot.com/

https://www.linkedin.com/groups/122787

---

You received this message because you are subscribed to the Google Groups "Materials & Welding" group.

To unsubscribe from this group and stop receiving emails from it, send an email to materials-weld...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/0ca6ac61-bff9-444e-bc40-80249c545c8dn%40googlegroups.com.

mahesh chilukamari

Apr 1, 2021, 5:33:50 AM4/1/21

to material...@googlegroups.com

Hi,

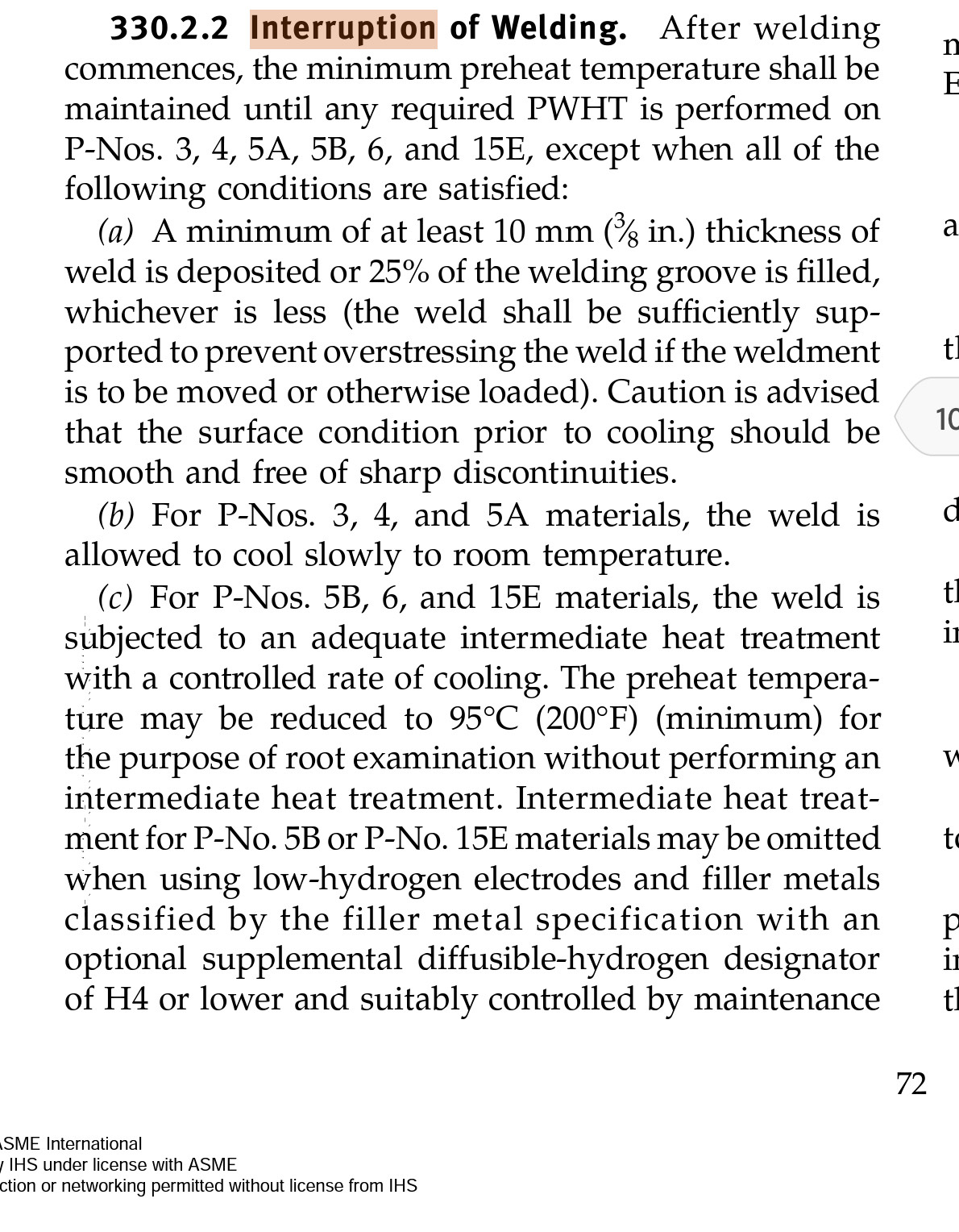

Refer to below from ASME B31.1

--

Kannayeram Gnanapandithan

Apr 1, 2021, 7:10:03 AM4/1/21

to materials-welding

referring code

If it is ASME, no restriction

THANKS & BEST REGARDS,

KG.PANDITHAN, BE, IWE, CSWIP 3.1,

ISO 9712 Level 2 in VT,

ASNT-Level II in PT,MT,RT & UT,

LA ISO 9001-2015,

International Welding Engineer.

CONSULTANT-WELDING & QUALITY

Mobile no: +919940739349

--

sankar bombay

Apr 1, 2021, 11:14:14 PM4/1/21

to material...@googlegroups.com

i am looking ASME VIII div1 , requirement same above as per project specification below details , I am looking for <19mm

P1 through P5B materials with wall thickness 19 mm (0.75 in.) shall only be

interrupted provided a minimum of 10 mm (0.375 in.) of weld metal has been deposited or 25 percent of the weld

groove has been filled, whichever is greater. If welding is interrupted, the weld shall be covered with adequate

insulation to ensure slow cooling. The partially completed weld shall be 100 percent MT-inspected prior to

resuming welding.

interrupted provided a minimum of 10 mm (0.375 in.) of weld metal has been deposited or 25 percent of the weld

groove has been filled, whichever is greater. If welding is interrupted, the weld shall be covered with adequate

insulation to ensure slow cooling. The partially completed weld shall be 100 percent MT-inspected prior to

resuming welding.

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAOgMkxFmV3eyTp9POam51Aonan%2BAau%2B%3DkiBO5cYQ%2BqYLWE%3DQcw%40mail.gmail.com.

shankar

George Dilintas

Apr 1, 2021, 11:14:14 PM4/1/21

to material...@googlegroups.com

Why you are trying to find problems when there is not

--

sankar bombay

Apr 1, 2021, 11:14:14 PM4/1/21

to material...@googlegroups.com

Brother

What about stress concentration and Oxidation of weld material , fast cooling at open atmosphere, How they will maintain the interpass temperature to avoid delay cracks

these are the thing to be considered for low thickness , if i am wrong let me correct myself

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAJzm4ePc_h0Rk2n-fKNTrrC4YvyqgU-mJ7ru-URZQJe_qL%3Dh3w%40mail.gmail.com.

shankar

sankar bombay

Apr 1, 2021, 11:14:14 PM4/1/21

to material...@googlegroups.com

cs material

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CADder3OvQW%2BCv0cZt4DwxELXW15MwvN5R23UAQ52t4VV-Lcccw%40mail.gmail.com.

shankar

Vishwas Keskar

Apr 1, 2021, 11:38:21 PM4/1/21

to material...@googlegroups.com

10mm Carbon steel

No problem will be there.

Just carry out Visual Inspection of the weld and proceed for subsequent Welding

To view this discussion on the web visit https://groups.google.com/d/msgid/materials-welding/CAAyDEeYRVztSMJz1fLmx_%2BfSGUR197JEKv5v78c7ND6iBqKrYw%40mail.gmail.com.

satesh kumar

Apr 2, 2021, 6:55:26 AM4/2/21

to Materials & Welding

according to you its good engineering practice?, all problem finding will give good result , all code book they finding problem and solve result at next edition

Vinay Thattey

Apr 4, 2021, 10:36:49 PM4/4/21

to material...@googlegroups.com

Need more details . Material to be welded i.r P No etc

--

Xuân Thông

Apr 5, 2021, 4:28:56 AM4/5/21

to material...@googlegroups.com

Hi sir,

The stop welding may be to check any cold cracking if any prior to weld the next layers

Vào Th 5, 1 thg 4, 2021 vào lúc 13:51 sankar krishnan <sankar...@gmail.com> đã viết:

Dear All ,In our Pressure vessel project 10mm thickness plate they using (GTAW+SAW) process , They have welded GTAW with 4 mm of 10mm thickness and leave open for 1 days .. I like to Know what is the interruption limitations to stop welding Limits for <19mm thicknessPlease send me code documents

--

Reply all

Reply to author

Forward

0 new messages