planning for a painting line

24 views

Skip to first unread message

Tim Snels

Jun 16, 2021, 10:19:25 AM6/16/21

to frePPLe users

Does anyone know what is the best way to plan a painting line?

I have an epoxy coating line with a chain conveyor. I can hang parts below each other and next to each other.

One tour of the line takes roughly 30minutes, but since it's a continuous loop I can continuously hang pieces and take off pieces.

Until now we always considered painting of pieces as one full day. It doesn't matter if I have 1 order or 10, we just take one day to start the ovens, prepare the line, paint the pieces, unload the parts,...

When I set the operation as time_per (30 minutes) then my total time is way off.

If I set the operation to fixed_time (8hours) then the total time is okay for a single order, but if I have multiple orders it takes X times 8 hours which is also way off.

Can I somehow create a schedule so when I need parts at the assembly, minimum 1 day before it just lists all the orders at the painting line without really scheduling it?

Steve Blamey

Jun 16, 2021, 10:55:48 AM6/16/21

to freppl...@googlegroups.com

Hi Tim

Have you looked at the different resource types?

Perhaps one of the bucketized types would work for you, see https://frepple.org/docs/current/model-reference/resources.php

Best regards

Steve

--

You received this message because you are subscribed to the Google Groups "frePPLe users" group.

To unsubscribe from this group and stop receiving emails from it, send an email to frepple-user...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/frepple-users/ead665d8-53ef-4b74-9ec0-0a71e573d318n%40googlegroups.com.

Tim Snels

Jun 16, 2021, 1:07:57 PM6/16/21

to frePPLe users

Hi Steve,

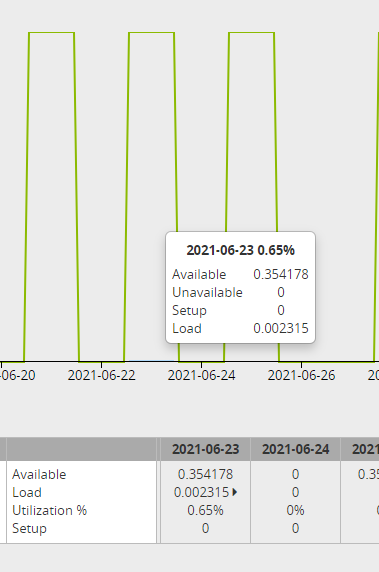

That seems to work although now I see in the plan that the utilization% remains at 0.65% and the bar graph is not showing anything. I adjusted the times so the total time for orders that day is 8hours.

Maybe it is normal that it doens't show a bar graph or anything since it is not a detailed plan as a bucket_day, but then where does the 0.65% come from?

Steve Blamey

Jun 16, 2021, 2:14:17 PM6/16/21

to freppl...@googlegroups.com

Hi Tim

This is not something I've had to model before. But you could try making the paint operation a fixed time of 8 hours, so it doesn't vary with the order quantity.

Then, set the resource to be a quantity bucket with quantity set to the maximum number of items that the painting line can handle each day.

Also check your available calendar and ensure that the value is 1.

Best regards

Steve

To view this discussion on the web visit https://groups.google.com/d/msgid/frepple-users/3127b7e4-6b87-4987-8d98-80b87eda3e15n%40googlegroups.com.

Reply all

Reply to author

Forward

0 new messages