Optimisation of Si(100) slab does not converge

142 views

Skip to first unread message

DMITRII Drugov

Nov 29, 2020, 8:24:02 PM11/29/20

to cp2k

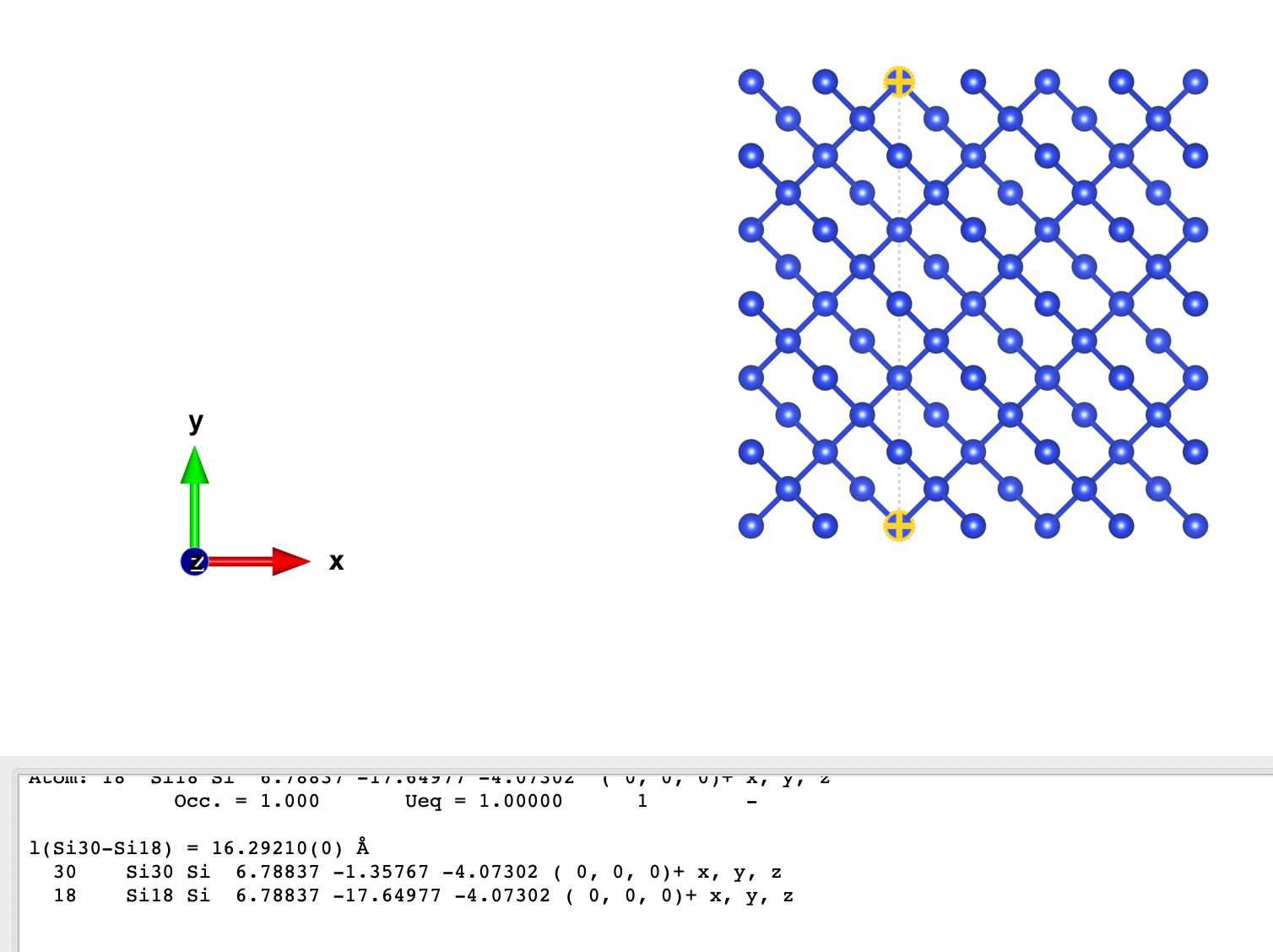

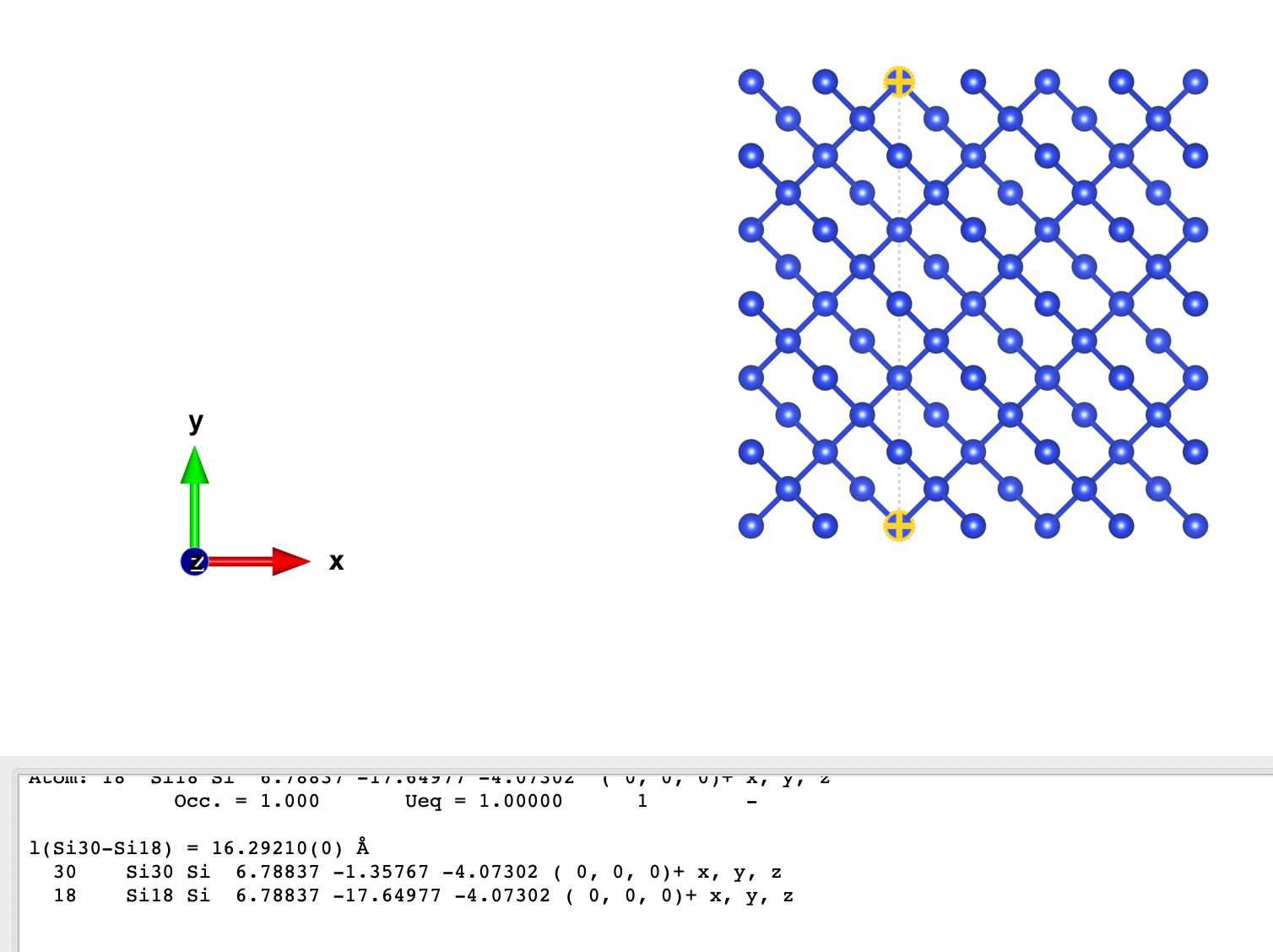

Good day dear CP2K users, could you please have a look at my .in file to see did I specify ABC cell parameters and ALPHA_BETA_GAMMA for Si(100) with 16.29210*16.29210*5.76 A^3. I am using TZVP-MOLOPT-GTH and I allowed two top layer to relax while other bulk part is frozen. In total it only 42 atoms our of 85 is under relaxation. My system didn't reach any convergence yet, despite I run it for 30 hour on supercomputer with 120 GB memory and 36 CPU. However, I used same .in file for gold and Na slabs and with around 70-60 atoms with DZVP, and it converged within 1-2 hours. Do you think it's normal for TZVP, should I wait longer? Or smth wrong with my .in setting?

Regards,

Dmitrii

-------- Informations at step = 3 ------------

Optimization Method = LBFGS

Total Energy = 2.9038335460

Real energy change = -14.0555995686

Decrease in energy = YES

Used time = 15200.012

Convergence check :

Max. step size = 0.3482436711

Conv. limit for step size = 0.0030000000

Convergence in step size = NO

RMS step size = 0.0816981844

Conv. limit for RMS step = 0.0015000000

Convergence in RMS step = NO

Max. gradient = 1.6813091629

Conv. limit for gradients = 0.0004500000

Conv. for gradients = NO

RMS gradient = 0.4396446909

Conv. limit for RMS grad. = 0.0003000000

Conv. for gradients = NO

my setting are:

&GLOBAL

PROJECT Si100_optimisation

RUN_TYPE GEO_OPT

PRINT_LEVEL MEDIUM

&END GLOBAL

&FORCE_EVAL

METHOD QS

&DFT

BASIS_SET_FILE_NAME BASIS_MOLOPT

POTENTIAL_FILE_NAME GTH_POTENTIALS

CHARGE 0

MULTIPLICITY 1

&MGRID

CUTOFF 800

NGRIDS 5

REL_CUTOFF 70

&END MGRID

&QS

EPS_DEFAULT 1.0E-12

WF_INTERPOLATION ASPC

&END QS

&SCF

SCF_GUESS ATOMIC

EPS_SCF 1.0E-7

MAX_SCF 1000

CHOLESKY INVERSE

ADDED_MOS 20

&SMEAR ON

METHOD FERMI_DIRAC

ELECTRONIC_TEMPERATURE [K] 300

&END SMEAR

&DIAGONALIZATION

ALGORITHM STANDARD

&END DIAGONALIZATION

&MIXING

METHOD BROYDEN_MIXING

ALPHA 0.4

NBROYDEN 8

&END MIXING

&END SCF

&XC

&XC_FUNCTIONAL

&PBE

&END PBE

&END XC_FUNCTIONAL

&vdW_POTENTIAL

DISPERSION_FUNCTIONAL PAIR_POTENTIAL

&PAIR_POTENTIAL

PARAMETER_FILE_NAME dftd3.dat

TYPE DFTD3

REFERENCE_FUNCTIONAL PBE

R_CUTOFF 15.0

&END PAIR_POTENTIAL

&END vdW_POTENTIAL

&END XC

&POISSON

PERIODIC xy

POISSON_SOLVER ANALYTIC

&END POISSON

&END DFT

&SUBSYS

&CELL

ABC 16.404 16.404 50.0

ALPHA_BETA_GAMMA 90.0 90.0 120.0

PERIODIC xy

&END CELL

&COORD

Si 17.64977 -17.64977 -4.07302

Si 17.64977 -12.21907 -4.07302

Si 17.64977 -6.78837 -4.07302

Si 17.64977 -1.35767 -4.07302

Si 12.21907 -17.64977 -4.07302

Si 16.29210 -16.29210 -5.43070

Si 13.57675 -13.57675 -5.43070

Si 14.93442 -14.93442 -4.07302

Si 12.21907 -12.21907 -4.07302

Si 16.29210 -10.86140 -5.43070

Si 13.57675 -8.14605 -5.43070

Si 14.93442 -9.50372 -4.07302

Si 12.21907 -6.78837 -4.07302

Si 16.29210 -5.43070 -5.43070

Si 13.57675 -2.71535 -5.43070

Si 14.93442 -4.07302 -4.07302

Si 12.21907 -1.35767 -4.07302

Si 6.78837 -17.64977 -4.07302

Si 10.86140 -16.29210 -5.43070

Si 8.14605 -13.57675 -5.43070

Si 9.50372 -14.93442 -4.07302

Si 6.78837 -12.21907 -4.07302

Si 10.86140 -10.86140 -5.43070

Si 8.14605 -8.14605 -5.43070

Si 9.50372 -9.50372 -4.07302

Si 6.78837 -6.78837 -4.07302

Si 10.86140 -5.43070 -5.43070

Si 8.14605 -2.71535 -5.43070

Si 9.50372 -4.07302 -4.07302

Si 6.78837 -1.35767 -4.07302

Si 1.35767 -17.64977 -4.07302

Si 5.43070 -16.29210 -5.43070

Si 2.71535 -13.57675 -5.43070

Si 4.07302 -14.93442 -4.07302

Si 1.35767 -12.21907 -4.07302

Si 5.43070 -10.86140 -5.43070

Si 2.71535 -8.14605 -5.43070

Si 4.07302 -9.50372 -4.07302

Si 1.35767 -6.78837 -4.07302

Si 5.43070 -5.43070 -5.43070

Si 2.71535 -2.71535 -5.43070

Si 4.07302 -4.07302 -4.07302

Si 1.35767 -1.35767 -4.07302

Si 17.64977 -14.93442 -1.35767

Si 17.64977 -9.50372 -1.35767

Si 17.64977 -4.07302 -1.35767

Si 14.93442 -17.64977 -1.35767

Si 13.57675 -16.29210 -2.71535

Si 16.29210 -13.57675 -2.71535

Si 14.93442 -12.21907 -1.35767

Si 12.21907 -14.93442 -1.35767

Si 13.57675 -10.86140 -2.71535

Si 16.29210 -8.14605 -2.71535

Si 14.93442 -6.78837 -1.35767

Si 12.21907 -9.50372 -1.35767

Si 13.57675 -5.43070 -2.71535

Si 16.29210 -2.71535 -2.71535

Si 14.93442 -1.35767 -1.35767

Si 12.21907 -4.07302 -1.35767

Si 9.50372 -17.64977 -1.35767

Si 8.14605 -16.29210 -2.71535

Si 10.86140 -13.57675 -2.71535

Si 9.50372 -12.21907 -1.35767

Si 6.78837 -14.93442 -1.35767

Si 8.14605 -10.86140 -2.71535

Si 10.86140 -8.14605 -2.71535

Si 9.50372 -6.78837 -1.35767

Si 6.78837 -9.50372 -1.35767

Si 8.14605 -5.43070 -2.71535

Si 10.86140 -2.71535 -2.71535

Si 9.50372 -1.35767 -1.35767

Si 6.78837 -4.07302 -1.35767

Si 4.07302 -17.64977 -1.35767

Si 2.71535 -16.29210 -2.71535

Si 5.43070 -13.57675 -2.71535

Si 4.07302 -12.21907 -1.35767

Si 1.35767 -14.93442 -1.35767

Si 2.71535 -10.86140 -2.71535

Si 5.43070 -8.14605 -2.71535

Si 4.07302 -6.78837 -1.35767

Si 1.35767 -9.50372 -1.35767

Si 2.71535 -5.43070 -2.71535

Si 5.43070 -2.71535 -2.71535

Si 4.07302 -1.35767 -1.35767

Si 1.35767 -4.07302 -1.35767

&END COORD

&KIND Au

BASIS_SET DZVP-MOLOPT-SR-GTH

POTENTIAL GTH-PBE-q11

&END KIND

&KIND F

BASIS_SET TZVP-MOLOPT-GTH

POTENTIAL GTH-PBE-q7

&END KIND

&KIND O

BASIS_SET TZVP-MOLOPT-GTH

POTENTIAL GTH-PBE-q6

&END KIND

&KIND C

BASIS_SET TZVP-MOLOPT-GTH

POTENTIAL GTH-PBE-q4

&END KIND

&KIND Si

BASIS_SET TZVP-MOLOPT-GTH

POTENTIAL GTH-PBE-q4

&END KIND

&KIND S

BASIS_SET TZVP-MOLOPT-GTH

POTENTIAL GTH-PBE-q6

&END KIND

&KIND N

BASIS_SET TZVP-MOLOPT-GTH

POTENTIAL GTH-PBE-q5

&END KIND

&KIND Na

BASIS_SET DZVP-MOLOPT-SR-GTH

POTENTIAL GTH-PBE-q9

&END KIND

&END SUBSYS

&END FORCE_EVAL

&MOTION

&CONSTRAINT

&FIXED_ATOMS

COMPONENTS_TO_FIX XYZ

LIST 1..43

&END FIXED_ATOMS

&END CONSTRAINT

&GEO_OPT

OPTIMIZER LBFGS

MAX_ITER 300

&END GEO_OPT

&END MOTION

Lucas Lodeiro

Nov 29, 2020, 10:21:43 PM11/29/20

to cp...@googlegroups.com

Hi DMITRII,

I am not an expert on silicon systems, but I read plenty times that (001) silicon surfaces presents reconstruction when the surface is expanded (the reconstruction is not possible for the unitary surface cell), as your case. This could explain why do you have this problem with silicon and not with Au and Na. The first time that I read about this was "density functional theory: a practical introduction" of Janice Steckel and David Scholl, and in some papers, like this: https://www.researchgate.net/figure/Pictorial-view-of-the-100-surface-of-silicon-a-unrelaxed-surface-b-relaxed_fig5_282648906

Another thing is, Why do you use diagonalization instead of OT method? I expect that silicon system (even surface systems) were not metals... then the OT method will be faster.

Regards

Lucas Lodeiro

--

You received this message because you are subscribed to the Google Groups "cp2k" group.

To unsubscribe from this group and stop receiving emails from it, send an email to cp2k+uns...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/cp2k/162639f5-a816-408c-b798-55a572c13fffn%40googlegroups.com.

DMITRII Drugov

Nov 29, 2020, 10:52:41 PM11/29/20

to cp2k

Thank you for your reply!

I need to compare adsorption energy for organic molecules on different surfaces (Na, Au, Si, and C). I successfully used diagonalization for Na and Au as they are metals. However, I am not sure if I use OT for Si and C, it would be accurate to compare Eads with those of Na and Au. What do you think?

Do you have any suggestion how to expand Si surface to allow reconstructing?

Do you think fo graphite I also cannot use unitary cell?

Regards,

Dmitrii

fabia...@gmail.com

Nov 30, 2020, 4:36:28 AM11/30/20

to cp2k

Dear Dmitrii,

Your cell is not correct, all angles should be 90 degree.

The total energy you reported is positive. This indicates that your structure is far from stable. Where did you get the coordinates from? Did you optimize bulk Si with cp2k before creating the slab?

Cheers,

Fabian

oh...@chem.uni-sofia.bg

Nov 30, 2020, 4:57:02 AM11/30/20

to cp...@googlegroups.com

Dear all, may someone advice me on the following.

I want to get the proper antiferromagnetic coupling of two Cu2+ ions in

a bimetallic complex. For this purpose I use the &BS subsection. Mu

question concerns the MULTIPLICITY keyword in this case. What should be

the MULTIPLICITY in this case? If I specify only MULTIPLICITY 1, which

is the actual spin state, cp2k will do non-spinpolarized calculation,

which is not the case. That is why I use UKS T and MULTIPLICITY 1.

Is that correct setting?

Best regards,

Petko

I want to get the proper antiferromagnetic coupling of two Cu2+ ions in

a bimetallic complex. For this purpose I use the &BS subsection. Mu

question concerns the MULTIPLICITY keyword in this case. What should be

the MULTIPLICITY in this case? If I specify only MULTIPLICITY 1, which

is the actual spin state, cp2k will do non-spinpolarized calculation,

which is not the case. That is why I use UKS T and MULTIPLICITY 1.

Is that correct setting?

Best regards,

Petko

Krack Matthias (PSI)

Nov 30, 2020, 5:03:12 AM11/30/20

to cp...@googlegroups.com

Dear Petko

Yes, I think so.

Matthias

-----Ursprüngliche Nachricht-----

Von: cp...@googlegroups.com <cp...@googlegroups.com> Im Auftrag von oh...@chem.uni-sofia.bg

Gesendet: Montag, 30. November 2020 10:57

An: cp...@googlegroups.com

Betreff: [CP2K:14316] Broken Symmetry and MULTIPLICITY

Yes, I think so.

Matthias

-----Ursprüngliche Nachricht-----

Von: cp...@googlegroups.com <cp...@googlegroups.com> Im Auftrag von oh...@chem.uni-sofia.bg

Gesendet: Montag, 30. November 2020 10:57

An: cp...@googlegroups.com

Betreff: [CP2K:14316] Broken Symmetry and MULTIPLICITY

--

You received this message because you are subscribed to the Google Groups "cp2k" group.

To unsubscribe from this group and stop receiving emails from it, send an email to cp2k+uns...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/cp2k/1ebe18da-1f28-53dc-e4e8-2f70afbf90ee%40chem.uni-sofia.bg.

You received this message because you are subscribed to the Google Groups "cp2k" group.

To unsubscribe from this group and stop receiving emails from it, send an email to cp2k+uns...@googlegroups.com.

oh...@chem.uni-sofia.bg

Nov 30, 2020, 5:05:38 AM11/30/20

to cp...@googlegroups.com, Krack Matthias (PSI)

Dear Matthias, thank you! I wanted to be sure I do not make mistake.

Petko

Petko

DMITRII Drugov

Nov 30, 2020, 6:57:39 PM11/30/20

to cp2k

Thank you for reply! I created two Si (100) systems with alpha beta gamma 90 90 90 and 90 90 120. The first system did't show any sign of convergence within 10 hours of simulation, whereas other fully converged (with 120 gamma degrees) at DZVP level within 19 hours. The system with 90 90 120 cell parameters performed about 66 steps within 19 hours, but the other 90 90 90 system performed only 2 steps for 10 hours. Before doing simulation, I created slab in avogadro and put in CP2K later. I wasn't sure should I choose 90 90 90 or 90 90 120 degree, as I saw smb published a work for Si (100) with 90 90 120 degrees cell parameters.

Here is my and ouput file for system with 90 90 120 cell angels.

Total Charge 0.002

!-----------------------------------------------------------------------------!

ENERGY| Total FORCE_EVAL ( QS ) energy (a.u.): -6.901440296115577

-------- Informations at step = 66 ------------

Optimization Method = LBFGS

Total Energy = -6.9014402961

Real energy change = -0.0000072318

Decrease in energy = YES

Used time = 883.680

Convergence check :

Max. step size = 0.0025436647

Conv. limit for step size = 0.0030000000

Convergence in step size = YES

RMS step size = 0.0006204331

Conv. limit for RMS step = 0.0015000000

Convergence in RMS step = YES

Max. gradient = 0.0001874079

Conv. limit for gradients = 0.0004500000

Conv. in gradients = YES

RMS gradient = 0.0000472944

Conv. limit for RMS grad. = 0.0003000000

Conv. in RMS gradients = YES

---------------------------------------------------

*******************************************************************************

*** GEOMETRY OPTIMIZATION COMPLETED ***

*******************************************************************************

Reply all

Reply to author

Forward

0 new messages