RUMBA 12-35V - maybe not, burned re-settable Fuse

1,946 views

Skip to first unread message

Bogdan Bednarczyk

Nov 10, 2013, 8:50:49 PM11/10/13

to connected-commu...@googlegroups.com

Hi guys,

I did get the Rumba from Reprapdiscount did i do something wrong?

--

Cheers

Bogdan

John Bosua

Nov 10, 2013, 9:35:34 PM11/10/13

to connected-commu...@googlegroups.com

Hey Bogdan,

You should have waited until you spoke to some of us!

You have to quite a bit of firmware current limiting to do before you just hook it up to 24 volts and press go.

Dont try any thing else until you speak to me at the space next.

Frankly I'm surprised it lasted 10 mins.

You seem to run at these things like a bull at a gate without any research and then get upset when it blows up.

I will talk you through it at the space next time I see you.

hopefully you just killed the heated bed mosfet which is way undersized anyway.

JB

--

You received this message because you are subscribed to the Google Groups "Connected Community HackerSpace" group.

To unsubscribe from this group and stop receiving emails from it, send an email to connected-community-h...@googlegroups.com.

To post to this group, send an email to connected-commu...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/CAOhh4dv71NfTn9%2BP7b0kkSs0eU3HaOjMGvUuaJoVnqbLJsueyA%40mail.gmail.com.

For more options, visit https://groups.google.com/groups/opt_out.

Stuart Young

Nov 11, 2013, 12:00:56 AM11/11/13

to CCHS

One thing of note:

This sort of thing happens when you connect a standard 12V heated bed to a board running a 24V supply.For reference, my Kapton based 24V heated bed produces about 200W and draws ~8.3A.

Also of note, the larger heated bed PTC fuse is only rated for 16V, so IMO it should not be sold as capable of running the heated bed at higher than 15V.

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/519C167C-E348-47C2-9EF0-AE575AEE1C19%40gmail.com.

--

Stuart Young (aka Cefiar)

Luke Weston

Nov 11, 2013, 1:42:32 AM11/11/13

to connected-commu...@googlegroups.com

If it really requires particular software configuration prior to plugging in power or else it blows up then that's pathetic engineering and user experience.

--

This email is intended only for the personal and confidential use of the human(s) named above. If intercepted by an extraterrestrial civilization, all opinions expressed in this email are my own and do not necessarily reflect the opinion of mankind as a whole.

Hardware should never ever be designed such that it is dependent on the software being put in a certain state, or never put in a certain state, or else it blows up. If the user specifically has to edit the code, set the HARDWARE_DONT_CATCH_FIRE variable, recompile and reflash the code to the board then they're doing something very, very wrong with hardware design.

Also, PPTCs are just crap at these power levels, I don't know why they've kept using them on the supposedly modern, advanced RUMBA/RAMBO designs.

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/CAPh9M%2BESc7sMzXGjk5Zox6H5WHpteb87kgHxbhxE%3DY%2BXLkS_UA%40mail.gmail.com.

For more options, visit https://groups.google.com/groups/opt_out.

--

This email is intended only for the personal and confidential use of the human(s) named above. If intercepted by an extraterrestrial civilization, all opinions expressed in this email are my own and do not necessarily reflect the opinion of mankind as a whole.

John Bosua

Nov 11, 2013, 1:55:44 AM11/11/13

to connected-commu...@googlegroups.com

Thats only if you are running a 12v extruder heater and 12v heated bed on 24v. the firmware has current limit functions which gives you the flexibility to do it. But not right out of the box. So it's not a crap design just not enough knowledge by the user.

I have been running it successfully for a year now with no problems (I did put in a bigger mosfet for the heated bed )

JB

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/CAEPooQG5%3DQTZH9L3yz1ZYcnAo_bQpeCcbjp0n7uMKtL25GsRuw%40mail.gmail.com.

Stuart Young

Nov 11, 2013, 1:58:29 AM11/11/13

to CCHS

Re: PTCs

RAMPS had them, which as a design is now a number of years old. Most of the newer electronics designs do not have them.

That said, RUMBA is a newer derivative, and they haven't yet learned the lesson Re: PTCs it seems.RAMPS had them, which as a design is now a number of years old. Most of the newer electronics designs do not have them.

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/CAEPooQG5%3DQTZH9L3yz1ZYcnAo_bQpeCcbjp0n7uMKtL25GsRuw%40mail.gmail.com.

Clifford Heath

Nov 11, 2013, 2:10:59 AM11/11/13

to connected-commu...@googlegroups.com

As an indication of what real pro-quality stuff can do, there are

Fluke multimeters which you can set on a 50 micro-amp range

and leave plugged into a 240V wall outlet, with no harm.

That's robust design :)

Clifford Heath.

> To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/C116FA68-5AB5-4304-B585-DDAA0D837AE1%40gmail.com.

Fluke multimeters which you can set on a 50 micro-amp range

and leave plugged into a 240V wall outlet, with no harm.

That's robust design :)

Clifford Heath.

Bogdan Bednarczyk

Nov 11, 2013, 2:40:49 AM11/11/13

to connected-commu...@googlegroups.com

I might be jumping into hot water with both feet,

but if the board said 12 -35v and i only use 24v,....then I agree with Luke its a poor consumer experience. Its either able or not able.........RAMPS had 12 and only after studding the design you are able to draw conclusions..

It should have a !!!! there or a NOTE: * with references... or something

but if the board said 12 -35v and i only use 24v,....then I agree with Luke its a poor consumer experience. Its either able or not able.........RAMPS had 12 and only after studding the design you are able to draw conclusions..

It should have a !!!! there or a NOTE: * with references... or something

I don't want to ask for everything because that can be annoying

But as you know, I will accept any help with thanks,

Thanks guys

Bogdan

Bogdan

--

Cheers

Bogdan

Cheers

Bogdan

John Bosua

Nov 11, 2013, 3:20:22 AM11/11/13

to connected-commu...@googlegroups.com

You can blame the board as much as you like but if you had a 24v heatbed and a 24v extruder heater and ran the board at 24v nothing would have burned up.

You chose to put 24volts into a 12volt cartridge heater and 24 volts into a 12 volt heatbed . What the hell did you think would happen!

12volts into 1.6 ohms =7.5 Amps = 90 watts

24volts into 1.6 ohms= 15 Amps =360 watts

Thats why your 11 amp fuse exploded into flames. (It may have survived if you had a big ass fan on it)

Both Michael and myself removed the fuses because we calculated the current draw was too high. Thats why I said you should have checked with us first.

It most definately was your fault the board blew up.

So dont keep blaming the RUMBA board .

JB

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/CAOhh4dupZBDCDjr0Qc6fMKnKt1WieAU00JL9SqFZkdTZZZnXXg%40mail.gmail.com.

Dave Chanter

Nov 11, 2013, 5:42:08 PM11/11/13

to connected-commu...@googlegroups.com

Hi All,

Please keep the conversation civil and relevant to the technical issues at hand.

Be excellent to each other is rule #1.

Be excellent to each other is rule #1.

Thanks

Dave Chanter

Darren Freeman

Nov 11, 2013, 9:31:59 PM11/11/13

to connected-commu...@googlegroups.com

Hi all,

I'm jumping in at this point because the consequences of this failure

could have been life-threatening. Please keep that in mind when you work

with power supplies that are capable of setting things on fire.

Inexperience, and failure to ask the right questions, can be deadly even

at 24 V.

On Mon, 2013-11-11 at 19:20 +1100, John Bosua wrote:

> You can blame the board as much as you like but if you had a 24v

> heatbed and a 24v extruder heater and ran the board at 24v nothing

> would have burned up.

True. But from what happened, you'd be one fault away from a fire.

The firmware fix is basically a work-around that clips the PWM duty to a

maximum value. Since PCB heated beds tend to require a bit more or a bit

less than the power supply that you actually have, it's useful to be

able to do this in firmware. It is critical, however, that you test what

happens if the software should fail unattended. You must have adequate

protection in hardware.

Once you rely on software to prevent fires, your system is a fatality

waiting to happen. It's bad enough that home-made printers don't have

thermal protection for the heated bed, but now you have one that relies

upon a bit continuing to toggle or else there might be a fire. If that

bit should become stuck on '1', or if the MOSFET should fail in the

usual manner, then you have a fire.

Bogdan has fallen for a known issue. By asking around, he could have

found out about this and saved himself some grief. So it is true that

being in a hurry has cost him.

But the board, as advertised, should have done the job, or at least not

burst into flames. This is most definitely not acceptable in a

commercial product. It does not meet the relevant standards.

If it was supplied by an Australian supplier, you are entitled to a

refund, and possibly even damages if something else was affected. (This

is what product liability insurance is for.) If you bought it from

overseas, then you are responsible for ensuring the standards compliance

of the items that you imported, so then it's "tough luck", and be glad

that you didn't burn down a building.

As you don't seem to have the knowledge to assess items for standards

compliance, you shouldn't buy items like this from overseas unless you

have a buddy who can check it for you. The same goes for people who

import cheap power supplies only to have someone suffer an electric

shock because they are poorly made. Lots of us have gotten bargains from

overseas, but we also know what to look out for. Bargain hunting of

power electronics is definitely not for beginners.

Local suppliers are more expensive, but they are responsible for

checking the quality of what they sell.

> Thats why your 11 amp fuse exploded into flames. (It may have survived

> if you had a big ass fan on it)

False. This is the very scenario that the fuse is intended to protect

against. This is like blaming someone for attempting to drive on their

spare tyre, which was supplied with the vehicle, but which failed right

away when you finally needed it.

As the trip current is highly dependent upon the airflow, putting a fan

on it is the last thing you should be doing. The fuse is designed to

reach a high temperature in order to open the circuit, but to survive

happily and cool down again when the fault is removed. By using a fan,

all you're doing is asking the 11 A fuse to behave as if it were a

higher rated fuse. You are defeating a safety feature in the process.

If you really want the fuse to stay closed at a higher current, you need

to install a higher rated fuse and also make the necessary changes to

the circuit, assuming the 11 A value was chosen for a good reason. As

John suggested, a better MOSFET is a good start. But then you have to

know if your PCB heated bed will survive at the higher current.

The symptoms that Bogdan describes are consistent with the fuse having

an inadequate voltage rating. Therefore, not only is the board not

protected against over current, but it is a fatality waiting to happen.

All this when it is being operated at the board's rated voltage and

under foreseeable fault conditions.

Somewhere along the chain of open hardware designer -> manufacturer ->

supplier, someone has overlooked the voltage rating of the fuse when

rating the board overall.

Bogdan has every right to feel let down by having a configuration issue

translate into a fireball.

> Both Michael and myself removed the fuses because we calculated the

> current draw was too high. Thats why I said you should have checked

> with us first.

I think everybody does this. These boards have a reputation for being

poorly designed and/or manufactured, and needing modification in order

to work with larger heated beds.

But if you replace the fuse with a wire link, you have to ensure that

somewhere in the system you are protected against fault conditions.

Otherwise, instead of the fuse becoming a fireball, it might have been

the 12 V heated bed running on 24 V that would have become the fireball.

It might have survived just fine at 25% duty or even 50% duty, but then

one day your MOSFET shorts and the whole printer goes up in flames. By

this time you might be printing unattended because it's worked

flawlessly for months.

Bogdan, I'm sorry that this happened to you, but from now on if you

build this type of circuit, you should expect to have someone more

experienced look it over before you plug it in. You are surrounded by

people who would gladly help you on this, John included. Be glad it was

just the fuse that caught fire. If you'd done like everybody else and

replaced the fuse with a wire link, but not had someone point out that

you're driving your bed too hard, you could have literally set fire to

the entire printer and the room it's sitting in.

> It most definately was your fault the board blew up.

> So dont keep blaming the RUMBA board .

John, the board is to blame if an 11 A fuse can catch fire at 15 A, or

even at 30 A. One of the people who designed/made/sold this board knows

just enough to kill someone.

For your peace of mind, Bogdan, I suggest that you install a

non-resettable fuse such as an auto blade style or an M205,

appropriately rated for the other components in the system (wires,

connectors, PCB traces, MOSFET, etc.). Power faults are rarely

self-clearing, and your life is worth much more than a bag of fuses.

Have fun,

Darren

I'm jumping in at this point because the consequences of this failure

could have been life-threatening. Please keep that in mind when you work

with power supplies that are capable of setting things on fire.

Inexperience, and failure to ask the right questions, can be deadly even

at 24 V.

On Mon, 2013-11-11 at 19:20 +1100, John Bosua wrote:

> You can blame the board as much as you like but if you had a 24v

> heatbed and a 24v extruder heater and ran the board at 24v nothing

> would have burned up.

The firmware fix is basically a work-around that clips the PWM duty to a

maximum value. Since PCB heated beds tend to require a bit more or a bit

less than the power supply that you actually have, it's useful to be

able to do this in firmware. It is critical, however, that you test what

happens if the software should fail unattended. You must have adequate

protection in hardware.

Once you rely on software to prevent fires, your system is a fatality

waiting to happen. It's bad enough that home-made printers don't have

thermal protection for the heated bed, but now you have one that relies

upon a bit continuing to toggle or else there might be a fire. If that

bit should become stuck on '1', or if the MOSFET should fail in the

usual manner, then you have a fire.

Bogdan has fallen for a known issue. By asking around, he could have

found out about this and saved himself some grief. So it is true that

being in a hurry has cost him.

But the board, as advertised, should have done the job, or at least not

burst into flames. This is most definitely not acceptable in a

commercial product. It does not meet the relevant standards.

If it was supplied by an Australian supplier, you are entitled to a

refund, and possibly even damages if something else was affected. (This

is what product liability insurance is for.) If you bought it from

overseas, then you are responsible for ensuring the standards compliance

of the items that you imported, so then it's "tough luck", and be glad

that you didn't burn down a building.

As you don't seem to have the knowledge to assess items for standards

compliance, you shouldn't buy items like this from overseas unless you

have a buddy who can check it for you. The same goes for people who

import cheap power supplies only to have someone suffer an electric

shock because they are poorly made. Lots of us have gotten bargains from

overseas, but we also know what to look out for. Bargain hunting of

power electronics is definitely not for beginners.

Local suppliers are more expensive, but they are responsible for

checking the quality of what they sell.

> Thats why your 11 amp fuse exploded into flames. (It may have survived

> if you had a big ass fan on it)

against. This is like blaming someone for attempting to drive on their

spare tyre, which was supplied with the vehicle, but which failed right

away when you finally needed it.

As the trip current is highly dependent upon the airflow, putting a fan

on it is the last thing you should be doing. The fuse is designed to

reach a high temperature in order to open the circuit, but to survive

happily and cool down again when the fault is removed. By using a fan,

all you're doing is asking the 11 A fuse to behave as if it were a

higher rated fuse. You are defeating a safety feature in the process.

If you really want the fuse to stay closed at a higher current, you need

to install a higher rated fuse and also make the necessary changes to

the circuit, assuming the 11 A value was chosen for a good reason. As

John suggested, a better MOSFET is a good start. But then you have to

know if your PCB heated bed will survive at the higher current.

The symptoms that Bogdan describes are consistent with the fuse having

an inadequate voltage rating. Therefore, not only is the board not

protected against over current, but it is a fatality waiting to happen.

All this when it is being operated at the board's rated voltage and

under foreseeable fault conditions.

Somewhere along the chain of open hardware designer -> manufacturer ->

supplier, someone has overlooked the voltage rating of the fuse when

rating the board overall.

Bogdan has every right to feel let down by having a configuration issue

translate into a fireball.

> Both Michael and myself removed the fuses because we calculated the

> current draw was too high. Thats why I said you should have checked

> with us first.

poorly designed and/or manufactured, and needing modification in order

to work with larger heated beds.

But if you replace the fuse with a wire link, you have to ensure that

somewhere in the system you are protected against fault conditions.

Otherwise, instead of the fuse becoming a fireball, it might have been

the 12 V heated bed running on 24 V that would have become the fireball.

It might have survived just fine at 25% duty or even 50% duty, but then

one day your MOSFET shorts and the whole printer goes up in flames. By

this time you might be printing unattended because it's worked

flawlessly for months.

Bogdan, I'm sorry that this happened to you, but from now on if you

build this type of circuit, you should expect to have someone more

experienced look it over before you plug it in. You are surrounded by

people who would gladly help you on this, John included. Be glad it was

just the fuse that caught fire. If you'd done like everybody else and

replaced the fuse with a wire link, but not had someone point out that

you're driving your bed too hard, you could have literally set fire to

the entire printer and the room it's sitting in.

> It most definately was your fault the board blew up.

> So dont keep blaming the RUMBA board .

even at 30 A. One of the people who designed/made/sold this board knows

just enough to kill someone.

For your peace of mind, Bogdan, I suggest that you install a

non-resettable fuse such as an auto blade style or an M205,

appropriately rated for the other components in the system (wires,

connectors, PCB traces, MOSFET, etc.). Power faults are rarely

self-clearing, and your life is worth much more than a bag of fuses.

Have fun,

Darren

Stuart Young

Nov 11, 2013, 10:10:05 PM11/11/13

to CCHS

The PTC 11A fuse used on RAMPS/RUMBA boards (Bourns MF-R1100) is rated for a max hold of 11A, definite trip at 22A, with a maximum voltage of 16V. It's supposed to be able to sustain a max of 100A, but only with heavy cooling.

The PTC 5A fuse used on RAMPS/RUMBA boards (Bourns MF-R500) is rated to a max hold of 5A, definite trip at 10A, with a maximum voltage of 30V, and a max current of 40A with heavy cooling.

The voltage rating is (supposedly) the max rating that the PTC fuse can withstand a direct short and still provide current protection. You go over that voltage, you risk all sorts of issues.

The time to trip however is the interesting bit, and proves to me that they're worthless to be used as fuses:

MF-R500 - 25A current - 14.5 seconds to trip

MF-R1100 - 40A current - 20.0 seconds to trip

Anything that takes more than 0.25 seconds, I don't consider useful as a fuse to protect against dead shorts of user misuse/abuse.

Spec sheet for reference: http://www.mouser.com/ds/2/54/mfr-72330.pdf

The reason that they chose an 11A PTC with this voltage rating is pretty simple: You can't get a higher current rating with a voltage rating greater than 16V, and RAMPS, as originally designed was only rated to 12V. RUMBA is a derivative of RAMPS.

I personally don't think RUMBA, as stands, should be marked as capable of 12-35V input.

Note that RUMBA, like RAMPS, has 2 voltage inputs. One for the Arduino/motors/hot end/fans, and one for the heated bed. I should also note that while the board does have "12V..35V" on the silk screen, it's next to the connector for the Arduino/motors/hot end/fans input. If this was JUST for the Arduino/motors/hot end/fans, then I would still say that is too much. The stepper drivers may barely be able to handle 35V, but the PTC fuse is then operating outside of it's max voltage.

PS: I have been pointing out the issues of PTC fuses on the RepRap forum for a long time (I run my systems exclusively on 24V, but I also have made sure that any modifications necessary to make them 24V have been performed). JohnnyR, the original designer of RAMPS (which he has abandoned working on) has since moved his NEW design RAMBO away from PTC fuses for this very reason.

--

You received this message because you are subscribed to the Google Groups "Connected Community HackerSpace" group.

To unsubscribe from this group and stop receiving emails from it, send an email to connected-community-h...@googlegroups.com.

To post to this group, send an email to connected-commu...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/1384223519.7567.80.camel%40buffy.sunnydale.

For more options, visit https://groups.google.com/groups/opt_out.

John Bosua

Nov 11, 2013, 10:18:21 PM11/11/13

to connected-commu...@googlegroups.com

I'll agree to disagree.

JB

JB

> --

> You received this message because you are subscribed to the Google Groups "Connected Community HackerSpace" group.

> To unsubscribe from this group and stop receiving emails from it, send an email to connected-community-h...@googlegroups.com.

> To post to this group, send an email to connected-commu...@googlegroups.com.

> To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/1384223519.7567.80.camel%40buffy.sunnydale.

> You received this message because you are subscribed to the Google Groups "Connected Community HackerSpace" group.

> To unsubscribe from this group and stop receiving emails from it, send an email to connected-community-h...@googlegroups.com.

> To post to this group, send an email to connected-commu...@googlegroups.com.

Darren Freeman

Nov 11, 2013, 10:32:24 PM11/11/13

to connected-commu...@googlegroups.com

On Tue, 2013-11-12 at 14:10 +1100, Stuart Young wrote:

> The PTC 11A fuse used on RAMPS/RUMBA boards (Bourns MF-R1100) is rated

> for a max hold of 11A, definite trip at 22A, with a maximum voltage of

> 16V. It's supposed to be able to sustain a max of 100A, but only with

> heavy cooling.

The "heavy cooling" rating isn't very useful when the data-sheet also

> The PTC 11A fuse used on RAMPS/RUMBA boards (Bourns MF-R1100) is rated

> for a max hold of 11A, definite trip at 22A, with a maximum voltage of

> 16V. It's supposed to be able to sustain a max of 100A, but only with

> heavy cooling.

tells you that it affects the trip current in an unspecified way :)

> The voltage rating is (supposedly) the max rating that the PTC fuse

> can withstand a direct short and still provide current protection. You

> go over that voltage, you risk all sorts of issues.

The temperature will go up with increasing voltage beyond the rating.

> The time to trip however is the interesting bit, and proves to me that

> they're worthless to be used as fuses:

>

> MF-R500 - 25A current - 14.5 seconds to trip

>

> MF-R1100 - 40A current - 20.0 seconds to trip

fuse.

As these boards are normally used with power supplies that have short

circuit protection, the resettable fuse is there to protect the wiring

and other components against overheating due to a long-term current that

the power supply can handle but something else can't.

The power supply needs to supply the inrush current while things are

warming up, and so your circuit breaker has a slow response. For

example, you might limit your duty cycle to 50% in software, so the PS

has to handle twice the average current. It will most likely deliver

that current continuously if the MOSFET shorts, and so you also need a

circuit breaker. When it trips, things will be hot, but hopefully not on

fire.

I've said before, that if we use the 3D printers with car batteries then

we also need to add a fast-blow fuse. The overload protection of the

power supply is critical to the safe operation of the system overall.

(As is the correct polarity :P)

> The reason that they chose an 11A PTC with this voltage rating is

> pretty simple: You can't get a higher current rating with a voltage

> rating greater than 16V, and RAMPS, as originally designed was only

> rated to 12V. RUMBA is a derivative of RAMPS.

wiring. And then sell the result to customers.

As I said, when the board was given this rating, it was by someone who

knows just enough to kill someone.

> I personally don't think RUMBA, as stands, should be marked as capable

> of 12-35V input.

Agreed.

> of 12-35V input.

> PS: I have been pointing out the issues of PTC fuses on the RepRap

> forum for a long time (I run my systems exclusively on 24V, but I also

> have made sure that any modifications necessary to make them 24V have

> been performed). JohnnyR, the original designer of RAMPS (which he has

> abandoned working on) has since moved his NEW design RAMBO away from

> PTC fuses for this very reason.

snapshots of a not-commercially-ready design. It's fair enough that an

early prototype might not work as planned, but then we have a variety of

manufacturers and sellers lending it legitimacy without adequate

testing.

I'd like to see one of these boards earn the CE mark through an

independent notified body. Customers should rightfully be demanding to

see the mark or else not buy it. But then it isn't a bargain any more,

since all of that costs money.

To cope with using early prototypes, new users have to ask around to

find out what's wrong with it and what they should do differently. (As

Bogdan just found out.)

Have fun,

Darren

Dave Chanter

Nov 11, 2013, 11:19:30 PM11/11/13

to connected-commu...@googlegroups.com

Its clear this topic has gotten some people fired up and your passionate about it, just another reminder to keep it civil.

Remember we are all here to learn and every mistake is an opportunity for us to learn from each other, particularly in this case where it is impossible for any one person to be aware of all the traps and 'work arounds' required for each and every type of open hardware design. There are simply too many to keep track of, eventually we all get caught out somewhere.

Toby Corkindale

Nov 11, 2013, 11:45:41 PM11/11/13

to connected-commu...@googlegroups.com

On 11 November 2013 17:42, Luke Weston <reindeer...@gmail.com> wrote:

> If it really requires particular software configuration prior to plugging in

> power or else it blows up then that's pathetic engineering and user

> experience.

>

> Hardware should never ever be designed such that it is dependent on the

> software being put in a certain state, or never put in a certain state, or

> else it blows up. If the user specifically has to edit the code, set the

> HARDWARE_DONT_CATCH_FIRE variable, recompile and reflash the code to the

> board then they're doing something very, very wrong with hardware design.

Exactly. Really, a good design should have safe, non-destructive

> power or else it blows up then that's pathetic engineering and user

> experience.

>

> Hardware should never ever be designed such that it is dependent on the

> software being put in a certain state, or never put in a certain state, or

> else it blows up. If the user specifically has to edit the code, set the

> HARDWARE_DONT_CATCH_FIRE variable, recompile and reflash the code to the

> board then they're doing something very, very wrong with hardware design.

defaults. Well, IMHO.

If it claims to accept variable voltage, then either default to the

highest voltage, autodetect, or default to a not-connected state and

require the user to set it. Or don't make the claims about variable

voltage!

Luke Weston

Nov 12, 2013, 4:03:19 AM11/12/13

to connected-commu...@googlegroups.com

Darren said:

"But the board, as advertised, should have done the job, or at least not

burst into flames. This is most definitely not acceptable in a

"But the board, as advertised, should have done the job, or at least not

burst into flames. This is most definitely not acceptable in a

commercial product. It does not meet the relevant standards."

The thing is though, a board like a RAMPS or RUMBA or whatever is not a finished consumer product that you plug in like a TV or whatever, it's just a naked PCB, it's a component for a DIY build that the user has to wire up correctly to correctly chosen devices such as power supplies and heating elements and sensors,

Even if the board was designed very well, you've still got all those variables about how it's wired up and used that can't be controlled by the designer or vendor of the board.

If you were selling, or buying, a completely assembled off-the-shelf consumer 3D printer that is an appliance, like a new PC or toaster, then you could certainly expect that the whole integrated system that is supplied works together successfully and safely, but for a board that is intended to be used and integrated as a component by somebody who knows what they are doing, you can supply documentation for what the specifications of your board are, what the maximum current ratings etc are, but that's really all that you can do, and the responsibility has to lie with the person doing that integration.

Even if the board was designed very well, you've still got all those variables about how it's wired up and used that can't be controlled by the designer or vendor of the board.

If you were selling, or buying, a completely assembled off-the-shelf consumer 3D printer that is an appliance, like a new PC or toaster, then you could certainly expect that the whole integrated system that is supplied works together successfully and safely, but for a board that is intended to be used and integrated as a component by somebody who knows what they are doing, you can supply documentation for what the specifications of your board are, what the maximum current ratings etc are, but that's really all that you can do, and the responsibility has to lie with the person doing that integration.

--

You received this message because you are subscribed to the Google Groups "Connected Community HackerSpace" group.

To unsubscribe from this group and stop receiving emails from it, send an email to connected-community-h...@googlegroups.com.

To post to this group, send an email to connected-commu...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/CABEgq95hPX1oVHphBmuQYTSGbiWUu9LraqJM1PvWftQkmiupVw%40mail.gmail.com.

For more options, visit https://groups.google.com/groups/opt_out.

Darren Freeman

Nov 12, 2013, 6:58:55 AM11/12/13

to connected-commu...@googlegroups.com

On Tue, 2013-11-12 at 20:03 +1100, Luke Weston wrote:

> Darren said:

> "But the board, as advertised, should have done the job, or at least

> not

> burst into flames. This is most definitely not acceptable in a

> commercial product. It does not meet the relevant standards."

>

> The thing is though, a board like a RAMPS or RUMBA or whatever is not

> a finished consumer product that you plug in like a TV or whatever,

> it's just a naked PCB, it's a component for a DIY build that the user

> has to wire up correctly to correctly chosen devices such as power

> supplies and heating elements and sensors,

OEM components are still required to perform as specified. The voltage

> Darren said:

> "But the board, as advertised, should have done the job, or at least

> not

> burst into flames. This is most definitely not acceptable in a

> commercial product. It does not meet the relevant standards."

>

> The thing is though, a board like a RAMPS or RUMBA or whatever is not

> a finished consumer product that you plug in like a TV or whatever,

> it's just a naked PCB, it's a component for a DIY build that the user

> has to wire up correctly to correctly chosen devices such as power

> supplies and heating elements and sensors,

rating is marked on the silk-screen, but it is wrong by a factor of two!

http://reprap.org/wiki/File:RRD-RUMBA_PCB.PNG

> Even if the board was designed very well, you've still got all those

> variables about how it's wired up and used that can't be controlled by

> the designer or vendor of the board.

system integrator who has to ensure that there is protection against

foreseeable faults, and in this case that means that some customers need

help from a buddy. You can't handle every fault condition, like mains

going into digital inputs, but this was wired up correctly with a simple

overload on a fault protected channel.

When a fault happens unattended, such as a wire desoldering itself and

falling onto another wire, it is usually when everything is wired up

correctly. This is exactly what that protection circuit is intended to

catch.

Perhaps Bogdan felt confident enough to power on by himself because of

the clearly visible fuses, and I think he deserves some credit for this.

He really has been let down by a shoddy design. Now the designer might

feel embarrassed by such comments, and I know that this design is

derived from another design with the same issue, but I'm not going to

blame a relative beginner who didn't even design the thing.

Had Bogdan been extra cautious, he might have wired up an external

circuit breaker for "extra protection", but the fuse would have had a

good chance of catching fire even then. The fact that the fuse got hot

enough to smoke means that it had tripped, and so the current at that

time would not have tripped another circuit breaker if that breaker

hadn't already tripped.

In the tripped state, almost the full supply voltage would have been

present across it, hence the high V^2/R losses that ultimately destroyed

the component. The voltage rating exists to limit the losses to a level

that sustains the tripped condition without causing damage. This could

still have happened to a 24 V heated bed if it had pulled slightly more

than the trip current for long enough, as it's mostly the voltage of the

supply that is relevant.

Anything that goes up in flames under such circumstances is hardly a

merchantable product. In this case, no fuse at all would have been

preferable to a placebo fuse. (Somebody might think they were

protected.)

Imagine that this weren't an OEM component, but instead a kit of

unassembled parts, based on a project in Silicon Chip magazine. (I

consider this the gold standard of how a board or a kit should be

supplied to hobbyists.) Now say that somebody discovers a flaw of this

magnitude. SC would publish a prominent erratum that the board is

absolutely not safe to use at the stated voltage without modifications.

The kit vendors would include this erratum with the kits, and either

include the revised components, or in this case, state that external

fusing is required INSTEAD OF the supplied fuses, if the user wishes to

go above the rating of the fuses. They might even update the silk-screen

to minimise confusion in the future, perhaps with two sets of ratings

for you to cross one out.

Instead, according to Stuart, the RAMPS forums have ignored him again

and again. People still sell the fully assembled boards without errata

and without updating the silk-screen. I don't see any mention of this

issue on the corresponding RepRap wiki:

http://reprap.org/wiki/RUMBA

If a Big Evil Corporation took this long to respond to a potentially

lethal design flaw, they would attract the ire of thousands.

Draw your own conclusions about whether it is the designers, the forums,

the suppliers or the users who should take corrective action. But Bogdan

has been let down by a shoddy product with no prominent warnings that it

performs other than as specified, and frankly, every one of these

unmodified boards is as deserving of a product recall as any consumer

product that tends to catch fire under foreseeable fault conditions.

The hacker defence should not apply unless you want to see some dead

hackers.

Have fun,

Darren

Bogdan Bednarczyk

Dec 2, 2013, 12:31:41 AM12/2/13

to connected-commu...@googlegroups.com

Thanks Guys

I have some time to come up for some air.

I've been so busy that that even reading the thread was too much, yet alone, try to find a sensible reply and defense strategy.

Anyway I am able to spend some time now on it, so cu tonite, I hope, all you people be there.I have some time to come up for some air.

I've been so busy that that even reading the thread was too much, yet alone, try to find a sensible reply and defense strategy.

--

You received this message because you are subscribed to the Google Groups "Connected Community HackerSpace" group.

To unsubscribe from this group and stop receiving emails from it, send an email to connected-community-h...@googlegroups.com.

To post to this group, send an email to connected-commu...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/1384257535.7567.168.camel%40buffy.sunnydale.

For more options, visit https://groups.google.com/groups/opt_out.

--

Cheers

Bogdan

Travis Andrews

Dec 4, 2013, 11:27:29 PM12/4/13

to connected-commu...@googlegroups.com, dar...@freemaninstruments.com

Interesting reading!

Hello,

I'm new to the group.

I also have a RUMBA, not connected to anything yet. I am planning on starting my Mini Kossel on a simple 12V 5A LCD brick as specified by Johann, the designer of the Mini Kossel. I won't be using a heated bed at that time, but in the near future I would like to switch to 24V. I already have the RepRapsDiscount Mk2B 12V&24V heated bed, and my MkIVB hot end has a Heater resistor with these specs: Axial, 5.6 ohm, 1%, 5W UB5C-5.6-ND. I can change that heater as needed for 24V.

My Motors are Sanyo Denki 103H5208-1242, which have these specs:

- Voltage Rating: 6.4VDC (Unipolar Connection) / 9.0VDC Bipolar Connection

- Supply Voltage: Up to 12-36VDC

- Rated Current: 1.2A (Unipolar Connection) / 1.0A (Bipolar Connection)

- Resistance: 1.6Ω

I would like to eventually get it running with 3 extruders, 6 steppers in total. I'm thinking 3 separate heater cartridges on my own custom 3 orifice hot end with thermally isolated sections.

After reading the above, I would like to ask (being mostly mechanically inclined) what modifications would you guys make to the RUMBA board in order to make it safer while running 24V in the above configuration? Can you specify fuses, MOSFET, etc...?

Thanks

Travis

Darren Freeman

Dec 5, 2013, 12:30:40 AM12/5/13

to Travis Andrews, connected-commu...@googlegroups.com

On Wed, 2013-12-04 at 20:27 -0800, Travis Andrews wrote:

> After reading the above, I would like to ask (being mostly

> mechanically inclined) what modifications would you guys make to the

> RUMBA board in order to make it safer while running 24V in the

> above configuration? Can you specify fuses, MOSFET, etc...?

I don't have this board, so the following is in addition to the advice

> After reading the above, I would like to ask (being mostly

> mechanically inclined) what modifications would you guys make to the

> RUMBA board in order to make it safer while running 24V in the

> above configuration? Can you specify fuses, MOSFET, etc...?

from someone else who has one. I also recommend that you have this

discussion in person a few times throughout your project.

It's clear that you need to remove or bypass the resettable fuses in

order to use an input voltage greater than 16 V. This is a design flaw

and it's not optional.

I recommend shorting them with a piece of heavy wire, (desoldering braid

also works well) and installing an external fuse in-line with each power

input. For a 20 A input, you could use auto blade style fuses with

in-line holders. Or you might like to line up some panel-mount M205

holders near where your power wires go into the printer.

If you wish to run a lower voltage heater from a higher voltage power

supply, you will need to configure your firmware to limit the maximum

PWM duty cycle. If you have proper fusing, you should blow a fuse in the

event that the duty cycle goes too high or a MOSFET shorts. You might

like to use a combination of a circuit breaker at the desired maximum

average current, and a fuse at say 50% higher current. The circuit

breaker will trip if you get the PWM duty a bit wrong for several

minutes, but the fuse will catch a sudden short circuit in far less time

than it takes to trip a circuit breaker.

If your heaters are rated for the same voltage as the input voltage, and

if you know that your power supply has current limiting at about the

same level as one of the fuses that you would have used anyway, then you

don't need to include that fuse. But make a note of this design decision

- if you later change your power supply, e.g. swapping in a car battery,

or going above the ratings of one of your heaters, then you must add in

those fuses for safety.

If you are relying on the protective features of your power supply, then

only that power supply must be used with the printer.

It is also common to replace the bed MOSFET on all of these boards, as

the one that was specified is bot inappropriate for the application, and

also crap by today's standards. You should aim for one with "logic

level" gate input, and a much lower Rds(on) like 2 milliohms. Stuart

Young has found some that he likes, I suggest talking to him if you're

not comfortable selecting one. If you do this, you can make it so that

they don't even get warm to touch (even without a heat-sink), when

running at a higher current. Do fortify the PCB traces with heavy wire,

and install better connectors to handle the extra current.

Have fun,

Darren

John Bosua

Dec 5, 2013, 1:28:31 AM12/5/13

to connected-commu...@googlegroups.com

Hi Darren, as a successful user of the rumba on 24 volts .

You only have to make changes to stuff if you are doing dangerous stuff like I do.

I have to change stuff because I choose to run my 12 volt cartridge heater on the extruder at 24 volts and that needs to have some firmware current limits set.

and I run my 12 volt heatbed at 24 volts with a large external mosfet and no fuse.

If you intend to run your 12 v heat bed at 24 volts you MUST have really good contact between the PCB and the aluminium heat bed plate . I put 5 screws in (one in the centre as well as the 4 perimiter screws )

and I use lots of thermal paste. You can't run a 24 volt setup on the 12v heatbed without an aluminium top otherwise it will fry the PCB.

And you have to back the off the current on the pololu stepper drivers.

So you see if you were to run a 24volt extruder cartridge heater and a 24 volt heatbed you dont need to do anything except reset the current on the pololu's

I removed the 11A fuse and bridged it.

So it is only a problem when you do risky stuff like that without thinking.

JB

You only have to make changes to stuff if you are doing dangerous stuff like I do.

I have to change stuff because I choose to run my 12 volt cartridge heater on the extruder at 24 volts and that needs to have some firmware current limits set.

and I run my 12 volt heatbed at 24 volts with a large external mosfet and no fuse.

If you intend to run your 12 v heat bed at 24 volts you MUST have really good contact between the PCB and the aluminium heat bed plate . I put 5 screws in (one in the centre as well as the 4 perimiter screws )

and I use lots of thermal paste. You can't run a 24 volt setup on the 12v heatbed without an aluminium top otherwise it will fry the PCB.

And you have to back the off the current on the pololu stepper drivers.

So you see if you were to run a 24volt extruder cartridge heater and a 24 volt heatbed you dont need to do anything except reset the current on the pololu's

I removed the 11A fuse and bridged it.

So it is only a problem when you do risky stuff like that without thinking.

JB

> --

> You received this message because you are subscribed to the Google Groups "Connected Community HackerSpace" group.

> To unsubscribe from this group and stop receiving emails from it, send an email to connected-community-h...@googlegroups.com.

> To post to this group, send an email to connected-commu...@googlegroups.com.

> To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/1386221440.2407.105.camel%40buffy.sunnydale.

> You received this message because you are subscribed to the Google Groups "Connected Community HackerSpace" group.

> To unsubscribe from this group and stop receiving emails from it, send an email to connected-community-h...@googlegroups.com.

> To post to this group, send an email to connected-commu...@googlegroups.com.

Darren Freeman

Dec 5, 2013, 2:25:17 AM12/5/13

to connected-commu...@googlegroups.com

On Thu, 2013-12-05 at 17:28 +1100, John Bosua wrote:

> Hi Darren, as a successful user of the rumba on 24 volts .

> You only have to make changes to stuff if you are doing dangerous stuff like I do.

> Hi Darren, as a successful user of the rumba on 24 volts .

> You only have to make changes to stuff if you are doing dangerous stuff like I do.

> So you see if you were to run a 24volt extruder cartridge heater and a 24 volt heatbed you dont need to do anything except reset the current on the pololu's

> So it is only a problem when you do risky stuff like that without thinking.

You might not have blown up your PTC fuses yet, but they're not rated

for more than 16 V. It says so right on the data-sheet.

As you say, you removed yours, so it's hard for you to observe what

would have happened.

If you trip the PTC fuse on 24 V, you can expect it to fry. It doesn't

matter whether you are taking risks or not, if you ever manage to trip

the fuse it will fry. That shouldn't be the case, you might as well

replace it with a fuse that works properly.

I don't know how to explain it any clearer than that. The fuse has a

rating. It's not rated for 24V. You don't notice until you trip it,

because it always has about 0 V across it when it's closed.

My advice to people who want to avoid a fire, is don't leave it how it

is even if you think you're not being risky or doing stuff without

thinking. Shorts can and will happen when you're prototyping your own

machine.

Have fun,

Darren

Bogdan Bednarczyk

Dec 5, 2013, 7:53:28 PM12/5/13

to connected-commu...@googlegroups.com

Just to follow up what i did

at John B suggestion, I have done those changes

1. replaced the blown 11A re-settable fuse with 18AWG wire (only the one for the heat bed, right side of the board) I know I should have solder an appropriate fuse.....:(

2. changed the PIDTEMP settings from 255 to 55, but this wasn't heating the extruder for me (I had to manually adjust the temp during the print to 240 to stay at 230 during run) so I upped it up to 75 and it stays perfect on 230 deg. I also tried on 70 and it was still too low. the real temp lag below the set one by 7 deg with the fan on. I had to make it higher possibly because i forgot that I set the 21v power supply rather than 24v ... I will do another test later.at John B suggestion, I have done those changes

1. replaced the blown 11A re-settable fuse with 18AWG wire (only the one for the heat bed, right side of the board) I know I should have solder an appropriate fuse.....:(

ALL WORKS on 21v now, and i got the usable print finally, YEEPEE

well, one for now, i need 10

Thanks guys, I will battle on

Oh, I replaced the 48mm long motors with 60mm long

I think that the weight was too much for the 48mm or they ware just faulty (i tried 2 sets of those) ? i don't know,

configuration.h in Marlin these are changed to my settings. It used to be 255

----------------------

#define PIDTEMP

#define BANG_MAX 75 // limits current to nozzle while in bang-bang mode; 255=full current

#define PID_MAX 55 // limits current to nozzle while PID is active (see PID_FUNCTIONAL_RANGE below); 255=full current

#ifdef PIDTEMP

----------------------

#define PIDTEMP

#define BANG_MAX 75 // limits current to nozzle while in bang-bang mode; 255=full current

#define PID_MAX 55 // limits current to nozzle while PID is active (see PID_FUNCTIONAL_RANGE below); 255=full current

#ifdef PIDTEMP

----------------------

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/D7ADC973-05EA-4757-858D-8115FFD9886C%40gmail.com.

For more options, visit https://groups.google.com/groups/opt_out.

--

Cheers

Bogdan

John Bosua

Dec 5, 2013, 8:24:36 PM12/5/13

to connected-commu...@googlegroups.com

Thats great news Bogdan, as far as the extruder temp goes you will need to adjust the current limit settings up or down but only small increments until its stable for your heater block.

check your thermistor type and make sure thats correct as well .

if it rapidly heats up and overshoots the current limit is set too high if it doesn't get up to temp it is set too low.

you will find a happy spot where it works perfectly.

Maybe have a chat to Michael as he can help you with the PID values and how to set them up.

One other thing Bogdan, remind me to talk to you about the buffer settings next time I see you. (not important unless your printer pauses during complex shaped perimeters and leaves blobs)

JB

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/CAOhh4dvva%2BMsjHTPDkAZHg8AfScJFsNWZeb4%2B%2Bk91dnjNgzSTw%40mail.gmail.com.

Bogdan Bednarczyk

Dec 6, 2013, 2:33:58 AM12/6/13

to connected-commu...@googlegroups.com

No not pausing and leaving blobs,,,,,,,,

but

I got skips again, I stopped looking for about 20 min and bang,....but

I am quite happy to open another thread so we wont confuse the issues here

bogs

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/288E2843-8CE5-4A61-9CA2-3848EC03CCB7%40gmail.com.

--

Cheers

Bogdan

Travis Andrews

Dec 6, 2013, 5:09:25 PM12/6/13

to connected-commu...@googlegroups.com, Travis Andrews, dar...@freemaninstruments.com

Thanks for the detailed response Darren!

I looked at the schematic and my RUMBA, and while the schematic on the reprap.rog wiki lists different part numbers for the PTC fuses, which are rated for 30V, my RUMBA has the 16V rated PTC fuses (different part number than mentioned above though). Both of mine are 11A as well, and the board is silk screened for 11A... Not sure how many RUMBA revisions are out there!?

I also showed the board and schematic to some electrical engineers here at work and received the same guidance. I will replace the fuses, and the MOSFET for the heated bed. And when I switch over to 24V, everything will be rated for 24V.

Luke Weston

Dec 6, 2013, 9:58:37 PM12/6/13

to connected-commu...@googlegroups.com

There's the RUMBA as it was originally drawn up by the designer, and then there's the diverse range of possibilities of cheap clones that have been manufactured by cheap nasty Asia-based eBay/AliBaba/DealExtreme etc. sellers, who could be using goodness only knows what parts that may be different from what the original designer intended. This is the problem with this whole booming industry of cheap nasty generic sellers of clone Arduinos or Pololu stepper boards or whatever, that may or may not have a bill of material as the original designer specified it, and buying this sort of gear seems very popular in the RepRap/3D printer DIY community.

For example if you're using a 24V system, one thing you should check is to ensure that the capacitors on the main controller board (and Pololu-style stepper driver modules if used) on the 24V rail are rated for a voltage of >=35V. If they're cutting corners and cutting cost in a dodgy way, assuming that users will just use 12V, they may have only populated it with 16V or 25V caps.

For example if you're using a 24V system, one thing you should check is to ensure that the capacitors on the main controller board (and Pololu-style stepper driver modules if used) on the 24V rail are rated for a voltage of >=35V. If they're cutting corners and cutting cost in a dodgy way, assuming that users will just use 12V, they may have only populated it with 16V or 25V caps.

--

You received this message because you are subscribed to the Google Groups "Connected Community HackerSpace" group.

To unsubscribe from this group and stop receiving emails from it, send an email to connected-community-h...@googlegroups.com.

To post to this group, send an email to connected-commu...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/8efc4cc5-c83f-4c3d-b284-b533deca0ed7%40googlegroups.com.

Michael Sullivan

Dec 6, 2013, 9:58:47 PM12/6/13

to connected-community-hackerspace

If you have a current version Rumba then the Circuit etc on RepRap site is for a very old original version as many things have been changed

On Sat, Dec 7, 2013 at 9:09 AM, Travis Andrews <lot...@gmail.com> wrote:

--

You received this message because you are subscribed to the Google Groups "Connected Community HackerSpace" group.

To unsubscribe from this group and stop receiving emails from it, send an email to connected-community-h...@googlegroups.com.

To post to this group, send an email to connected-commu...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/8efc4cc5-c83f-4c3d-b284-b533deca0ed7%40googlegroups.com.

Darren Freeman

Dec 6, 2013, 10:47:17 PM12/6/13

to connected-commu...@googlegroups.com, Travis Andrews

On Fri, 2013-12-06 at 14:09 -0800, Travis Andrews wrote:

> I looked at the schematic and my RUMBA, and while the schematic on the

> reprap.rog wiki lists different part numbers for the PTC fuses, which

> are rated for 30V, my RUMBA has the 16V rated PTC fuses (different

> part number than mentioned above though). Both of mine are 11A as

> well, and the board is silk screened for 11A... Not sure how many

> RUMBA revisions are out there!?

I just double-checked the wiki..

> I looked at the schematic and my RUMBA, and while the schematic on the

> reprap.rog wiki lists different part numbers for the PTC fuses, which

> are rated for 30V, my RUMBA has the 16V rated PTC fuses (different

> part number than mentioned above though). Both of mine are 11A as

> well, and the board is silk screened for 11A... Not sure how many

> RUMBA revisions are out there!?

http://reprap.org/mediawiki/images/2/24/RRD-RUMBA_SCHEMATICS.png

The two fuses are MFR500 and MFR1100. MFR500 is 5A / 30V, whereas

MFR1100 is 11A / 16V. Chances are your board matches the schematic and

you were looking at a different fuse each time :)

So you shouldn't need to bypass the 5 A fuse if you stay below 30 V,

only the 11 A fuse.

If you look at the "time to trip", the 5 A fuse will pass 25 A for up to

about 15 s before it trips. They do offer protection against sitting on

8 A for half an hour and slowly smoking out the wiring, but you should

still add some fast blow fuses unless your power supply has overload

protection.

For example, most switch-mode power supplies will turn off more or less

instantly if you short the output wires. Some will sit there "hiccuping"

as they try to turn back on and sense that the short is still present,

while others will require that you turn them off and wait a few seconds

for them to reset. But a battery won't shut down, it could explode

either the wiring or the battery itself, so it will require at least one

proper fuse. The yellow "resettable fuses" are just too slow to prevent

tracks from exploding off the PCB, or guts popping out the side of

MOSFETs.

A friend of mine managed to accidentally set fire to some car jumper

leads that were hooked up to a car battery. Literally the leads were on

fire, I've seen the burn marks against the car body panels.

It's nice that they included little yellow circuit breakers, that's not

the problem. Just don't assume that they are enough on their own, and do

be aware that someone stuffed up the ratings on one of them, thus

stuffing up the ratings of the entire board. The heated bed is only

rated to 16 V until you modify it.

I've also just noticed that they have included better MOSFETs on the

latest RUBMA than the latest RAMPS board. The ones on RAMPS are nowhere

near suitable for the job, hence the big heat-sink that gets hot even

with a fan blowing on it. The ones on RUMBA are still borderline,

however, since they're not intended for a gate voltage of 5 V. Using the

PCB as a heat-sink, I'd expect them to get noticeably warm at 11 A, as

they would dissipate around 0.9 W to 1.2 W.

Just as an example of what's out there, Element14 currently has the

RJK0452DPB on special at $0.79 ea in lots of 5. It has the same

package/pinout as the one on RUMBA, and would drop about 0.35 W under

the same conditions. Then if you go up to 20 A, you're back at 1.3 W, so

it shouldn't get any warmer than it did at 11 A with the old MOSFET.

Have fun,

Darren

Bogdan Bednarczyk

Dec 6, 2013, 10:51:16 PM12/6/13

to connected-commu...@googlegroups.com

OH, thanks guys

Luke, It is really bad if that happens... cheap and nasty productions...

The boards I have maybe nasty, but I don't think its cheap .... mine cost US$99. that might be cheap in comparison with other boards but still expensive if you want to make things DIY

I check my caps, those that i can see....

3x rated >=35v

1x 50v

there might be some smaller ones> and under the poloulu's that i cant take out now..... trying the next print

Bogdan

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/CAB9i2Bbhw8zG_meRh8RUhCdDEkd_WPkVXd2Qg7hACy8gykeoaA%40mail.gmail.com.

--

Cheers

Bogdan

Darren Freeman

Dec 6, 2013, 10:57:40 PM12/6/13

to connected-commu...@googlegroups.com

On Sat, 2013-12-07 at 13:58 +1100, Michael Sullivan wrote:

> If you have a current version Rumba then the Circuit etc on RepRap

> site is for a very old original version as many things have been

> changed

If I Google for "RUMBA schematic", the first hit is the Wiki at

> If you have a current version Rumba then the Circuit etc on RepRap

> site is for a very old original version as many things have been

> changed

reprap.org.

I also found the source at ReprapDiscount:

http://forum.reprapdiscount.com/threads/rumba-board-open-source-files.616/

These are not in an open format, however, and it's very tempting to view

the PNG images at the RepRap Wiki. One should not have to shop around

opening various non-free file formats to be sure they are looking at the

correct schematic for a GPL board when a central Wiki exists.

I don't see anything else of relevance within the first 50 results.

Have fun,

Darren

Travis Andrews

Dec 8, 2013, 1:25:33 PM12/8/13

to connected-commu...@googlegroups.com, Travis Andrews, dar...@freemaninstruments.com

Darren, Luke, Michael,

Thanks for the replies.

I purchased my RUMBA direct from RepRapDiscount a few weeks ago, so it should be a clone...

But my components are different than the schematic and the board pictured on the wiki.

Here are some photos.

the PTC fuses are X16 GF1100 (16V 11A)

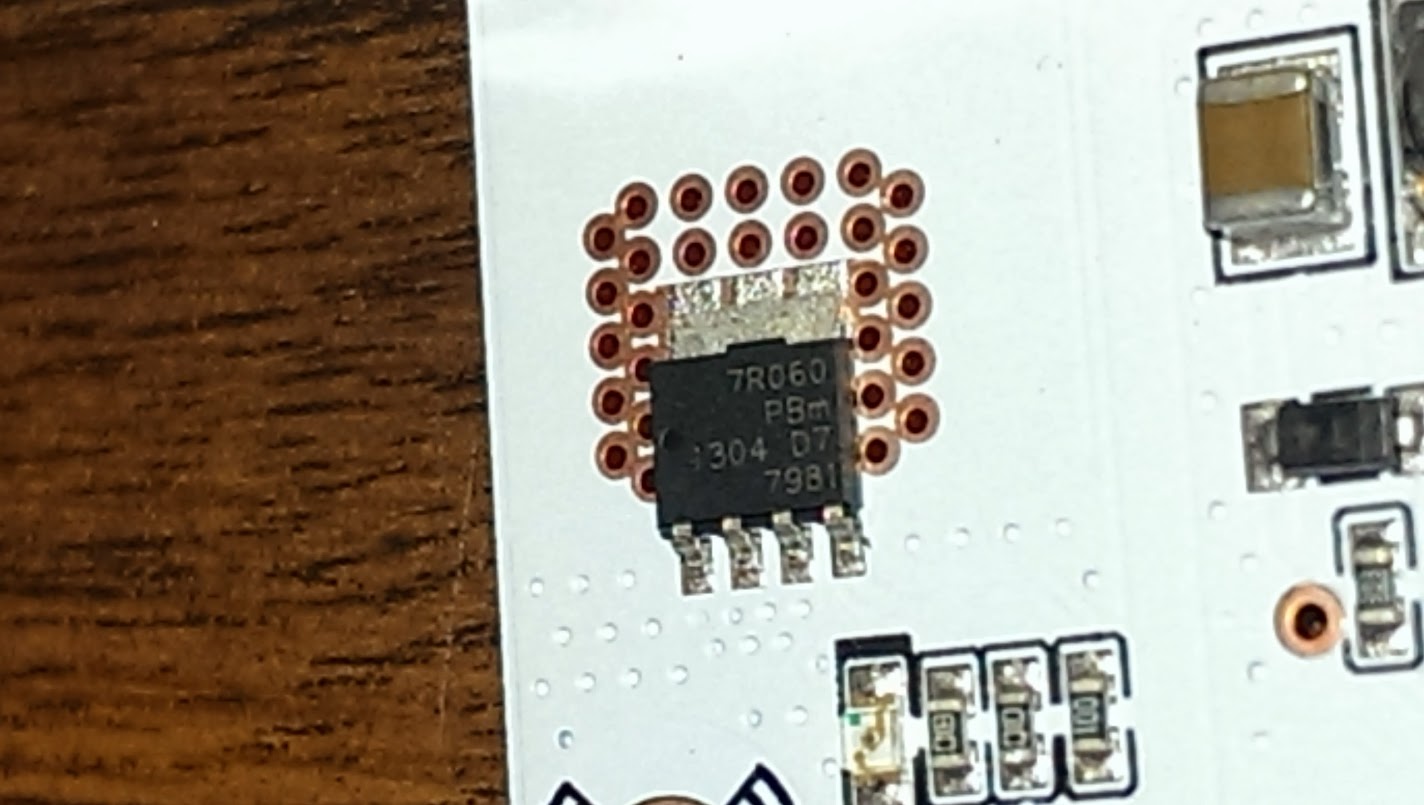

Here is the heated bed MOSFET 70-60 by NXP, doesn't look like a logic level gate input, I think I will replace that...

Message has been deleted

Travis Andrews

Dec 8, 2013, 1:40:12 PM12/8/13

to connected-commu...@googlegroups.com

I mean it should NOT be a clone! You can see the date on the sticker as 10/13.

The stepper drivers are all DRV8825 btw, based on the Pololu design apparently, but obviously not the exact same (the trimmers do have endstops though, unlike the Sainsmart drivers)

Luke Weston

Dec 9, 2013, 5:47:42 PM12/9/13

to connected-commu...@googlegroups.com

FYI the FET marked "7R060" is a PSMN7R0-60YS.

http://www.nxp.com/documents/data_sheet/PSMN7R0-60YS.pdf

http://www.nxp.com/documents/data_sheet/PSMN7R0-60YS.pdf

--

You received this message because you are subscribed to the Google Groups "Connected Community HackerSpace" group.

To unsubscribe from this group and stop receiving emails from it, send an email to connected-community-h...@googlegroups.com.

To post to this group, send an email to connected-commu...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/CAADMMbJ1FZE3OMufG071dmGk6XxX4%2BBg72VaM7MJu-iabh1M5g%40mail.gmail.com.

--

Travis Andrews

Dec 9, 2013, 6:10:52 PM12/9/13

to connected-commu...@googlegroups.com

yea I read that data sheet. Showed it to an electrical engineer here at work. He said it isn't a logic level gate input, and isn't necessarily ideal, but it does switch at 2V, so it should work with the 5V output from the Atmega 2560 chip, and should be good enough for 24V in this use (with a correct 24V heated bed).

To unsubscribe from this group and stop receiving emails from it, send an email to connected-community-hackerspace+unsubscribe@googlegroups.com.

To post to this group, send an email to connected-community-hacke...@googlegroups.com.

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/CAADMMbJ1FZE3OMufG071dmGk6XxX4%2BBg72VaM7MJu-iabh1M5g%40mail.gmail.com.

Michael Sullivan

Dec 9, 2013, 6:22:24 PM12/9/13

to connected-community-hackerspace

These stepper driver design is better then the polulu version as there is better heat dissipation and a greater surface area to mount the heat sinks

To view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/CAEPooQHYvm%2BbASgXTgcbozW_RGpREAVfSoNQq%3D3h4Du98MNj7A%40mail.gmail.com.

Bogdan Bednarczyk

Dec 9, 2013, 6:54:19 PM12/9/13

to connected-commu...@googlegroups.com

I thought that the one Travis have has more cooling area, the whole copper part is a cooling PAD?

you can still add more fins on the top is it is narrow enough to miss the trim potTo view this discussion on the web, visit https://groups.google.com/d/msgid/connected-community-hackerspace/CAB9i2Ban%3Dm_n-jAy5JOM_ER6MD0idrbJhMGpzm4c4zb2M%2B%3DDPQ%40mail.gmail.com.

--

Cheers

Bogdan

Clifford Heath

Dec 9, 2013, 8:01:31 PM12/9/13

to connected-commu...@googlegroups.com

On 10/12/2013, at 10:10 AM, Travis Andrews <lot...@gmail.com> wrote:

> yea I read that data sheet. Showed it to an electrical engineer here at work. He said it isn't a logic level gate input, and isn't necessarily ideal, but it does switch at 2V, so it should work with the 5V output from the Atmega 2560 chip, and should be good enough for 24V in this use (with a correct 24V heated bed).

> On Monday, December 9, 2013 3:47:42 PM UTC-7, Luke Weston wrote:

> FYI the FET marked "7R060" is a PSMN7R0-60YS.

>

> http://www.nxp.com/documents/data_sheet/PSMN7R0-60YS.pdf

Sorry, but your friend at work needs to learn how to read data sheets.

> yea I read that data sheet. Showed it to an electrical engineer here at work. He said it isn't a logic level gate input, and isn't necessarily ideal, but it does switch at 2V, so it should work with the 5V output from the Atmega 2560 chip, and should be good enough for 24V in this use (with a correct 24V heated bed).

> On Monday, December 9, 2013 3:47:42 PM UTC-7, Luke Weston wrote:

> FYI the FET marked "7R060" is a PSMN7R0-60YS.

>

> http://www.nxp.com/documents/data_sheet/PSMN7R0-60YS.pdf

Figure 6 shows that it clearly does NOT switch at 2V, even though section 6

shows Vgs(th) to have a *minimum* of 2V. The knee in the curve on Fig 6

is almost 4V, and I wouldn't regard the FET to be "on" until it reaches 4.5V.

Two facts from this data sheet are more relevant (than the threshold voltage)

to driving this FET from a microprocessor gate:

* Qg(tot) the total gate charge: 45nC (Vgs=10V, Vds=30V, close enough to 24V)

* Figure 8 shows that Rds(on) only reaches 7.5 mOhm at the full 5V, and is much

higher at 4.5V.

So, consider your microprocessor output pin. I have no idea what its output impedance

or maximum drive is, but it's common for these things to be >100ohm and <10mA.

Using this source impedance, you need to calculate the time required to charge the

gate to 4.5V. The effective gate capacitance is Cg is Q/V, specifically Qg(tot)/10,

which is 4.5nF. You need to charge this to 4.5V from a 5V source through 100 ohms.

The RC time constant here is then 0.45us (4.5nF*100R).

When you calculate the exponential curve, it takes 3.3 times the RC time constant

to reach 4.5V. One time constant gets you to about 0.7 of the source voltage, two

to 0.84, three to 0.89, and 3.3 to your 4.5v (90% of the 50V source). So it'll take

1.5us (3.3*0.45) for that output port to switch that FET.

During the switching time, the FET will have substantial current *and* voltage (i.e.

power dissipation). Take note that the impedance of your CPU pin may be different

in source (+5V) vs sink (0V) mode; it may pull up harder than it pulls down so you'll

have two different time constants.

Regardless, if you switch the FET at too high a frequency, you will overheat it.

I've used example numbers here, but you get the idea. The actual power dissipation

will depend on the Rds values while the gate is approaching the transition at 3.5V,

and you'd need to plot the area under the curve.

Or just use a buffer (aka gate driver) with a much lower output impedance, to reduce

the time constant. Bear in mind that switching too fast will create RF noise that you

will have to shield, snub, etc.

Here ends the MOSFET-driving lesson. You take the wheel now, and try not to

kangaroo-hop when you release the clutch.

Clifford Heath.

Darren Freeman

Dec 9, 2013, 10:17:25 PM12/9/13

to connected-commu...@googlegroups.com

On Tue, 2013-12-10 at 12:01 +1100, Clifford Heath wrote:

> On 10/12/2013, at 10:10 AM, Travis Andrews <lot...@gmail.com> wrote:

> > yea I read that data sheet. Showed it to an electrical engineer here at work. He said it isn't a logic level gate input, and isn't necessarily ideal, but it does switch at 2V, so it should work with the 5V output from the Atmega 2560 chip, and should be good enough for 24V in this use (with a correct 24V heated bed).

>

> > On Monday, December 9, 2013 3:47:42 PM UTC-7, Luke Weston wrote:

> > FYI the FET marked "7R060" is a PSMN7R0-60YS.

> >

> > http://www.nxp.com/documents/data_sheet/PSMN7R0-60YS.pdf

>

> Sorry, but your friend at work needs to learn how to read data sheets.

If you consider this in the context of the particular application,

> On 10/12/2013, at 10:10 AM, Travis Andrews <lot...@gmail.com> wrote:

> > yea I read that data sheet. Showed it to an electrical engineer here at work. He said it isn't a logic level gate input, and isn't necessarily ideal, but it does switch at 2V, so it should work with the 5V output from the Atmega 2560 chip, and should be good enough for 24V in this use (with a correct 24V heated bed).

>

> > On Monday, December 9, 2013 3:47:42 PM UTC-7, Luke Weston wrote:

> > FYI the FET marked "7R060" is a PSMN7R0-60YS.

> >

> > http://www.nxp.com/documents/data_sheet/PSMN7R0-60YS.pdf

>

> Sorry, but your friend at work needs to learn how to read data sheets.

although a competent person would never have specified this component,

it's passable.

Here's what I said earlier: "The ones on RUMBA are still borderline,

however, since they're not intended for a gate voltage of 5 V. Using the

PCB as a heat-sink, I'd expect them to get noticeably warm at 11 A, as

they would dissipate around 0.9 W to 1.2 W."

The range 0.9 W to 1.2 W is based on the data sheet and assuming between

PCB as a heat-sink, I'd expect them to get noticeably warm at 11 A, as

they would dissipate around 0.9 W to 1.2 W."

4.5 V and 5 V of static gate drive.

I can imagine a scenario where the gate drive goes below 4.5 V, such as

if you overload the 5 V regulator on the Arduino. Worst case dissipation

in the MOSFET is over 50 W under this scenario (at 24 V), so you will

smoke out your board. Hopefully this won't happen as you're not

experimenting with overloading your 5 V rail while attempting to print,

but most of us won't be thinking about this as we fiddle with the LCD

front panel which is driven from the 5 V rail. The back-light is 5V and

pulls a fair current.

If these parts were specified for cost reasons, they could have easily

built a 12 V gate drive circuit for a few cents more. Stuart Young is

doing this on his variant, and really it's the most sensible way to go.

I did this on the Prusa in the space. Requiring a MOSFET to be driven at

logic level is going to lead to compromises in its performance. Not even

using the right MOSFET is worse.

You want things to work reliably, not just most of the time.

> Regardless, if you switch the FET at too high a frequency, you will overheat it.

also you're switching 11 A without a free-wheeling current path - so it

may avalanche breakdown the MOSFET on every turn off. There are many

reasons why this circuit is only suitable for intermittent switching.

In this application, however, the firmware implements PWM at around 1

Hz, and it "works" albeit with excess heating. You do hear about failed

MOSFETs that fail shorted, and it's no surprise given that some of them

are dissipating a lot of power with fans blowing hard on them, and all

of them have no free-wheeling diode, snubbers, or any protection from

EMI and ESD from hitting the gate.

Combine the real possibility of a shorted MOSFET with the decision to

limit the power to the load by limiting the PWM duty cycle in firmware,

and you can see how easily this could lead to a fire.

Protection against excessive average currents is essential. Maybe you

want to pull 20 A during the initial warm-up, but under normal

circumstances it should reduce to 10 A after a few minutes, under

closed-loop control. Fine, so use a 15 A circuit breaker. That's what

they're for :)

Have fun,

Darren

Clifford Heath

Dec 10, 2013, 4:40:36 PM12/10/13

to connected-commu...@googlegroups.com

On 10/12/2013, at 2:17 PM, Darren Freeman <dar...@freemaninstruments.com> wrote:

> On Tue, 2013-12-10 at 12:01 +1100, Clifford Heath wrote:

>> Sorry, but your friend at work needs to learn how to read data sheets.

> If you consider this in the context of the particular application, it's passable.

> On Tue, 2013-12-10 at 12:01 +1100, Clifford Heath wrote:

>> Sorry, but your friend at work needs to learn how to read data sheets.

It was the "it does switch at 2V" that I objected to.

He was right to point out that it will sorta work though not ideal.

>> Regardless, if you switch the FET at too high a frequency, you will overheat it.

> Quite right, utterly useless in a PWM application beyond a few kHz. But

> also you're switching 11 A without a free-wheeling current path

For other's benefit, you can't suddenly stop current in an inductor.

It *will* find a path to deplete the stored magnetic energy, no matter

what voltage it has to create to force a path.

I hope someone found my post educational.

Clifford Heath.

Message has been deleted

Travis Andrews

Dec 10, 2013, 6:27:08 PM12/10/13

to connected-commu...@googlegroups.com

All good, and helpful info.

I may have misquoted my coworker, and also confused him by sending him another datasheet for a MOSFET with a logic level input at the same time. He was actually referring to the other MOSFET and not the NXP that comes on the RUMBA.

Darren Freeman

Dec 10, 2013, 10:08:05 PM12/10/13

to connected-commu...@googlegroups.com

On Wed, 2013-12-11 at 08:40 +1100, Clifford Heath wrote:

> >> Regardless, if you switch the FET at too high a frequency, you will overheat it.

> > Quite right, utterly useless in a PWM application beyond a few kHz. But

> > also you're switching 11 A without a free-wheeling current path

>

> Ouch. I hadn't looked at the circuit.

Understandable. You just don't expect to see things like this.