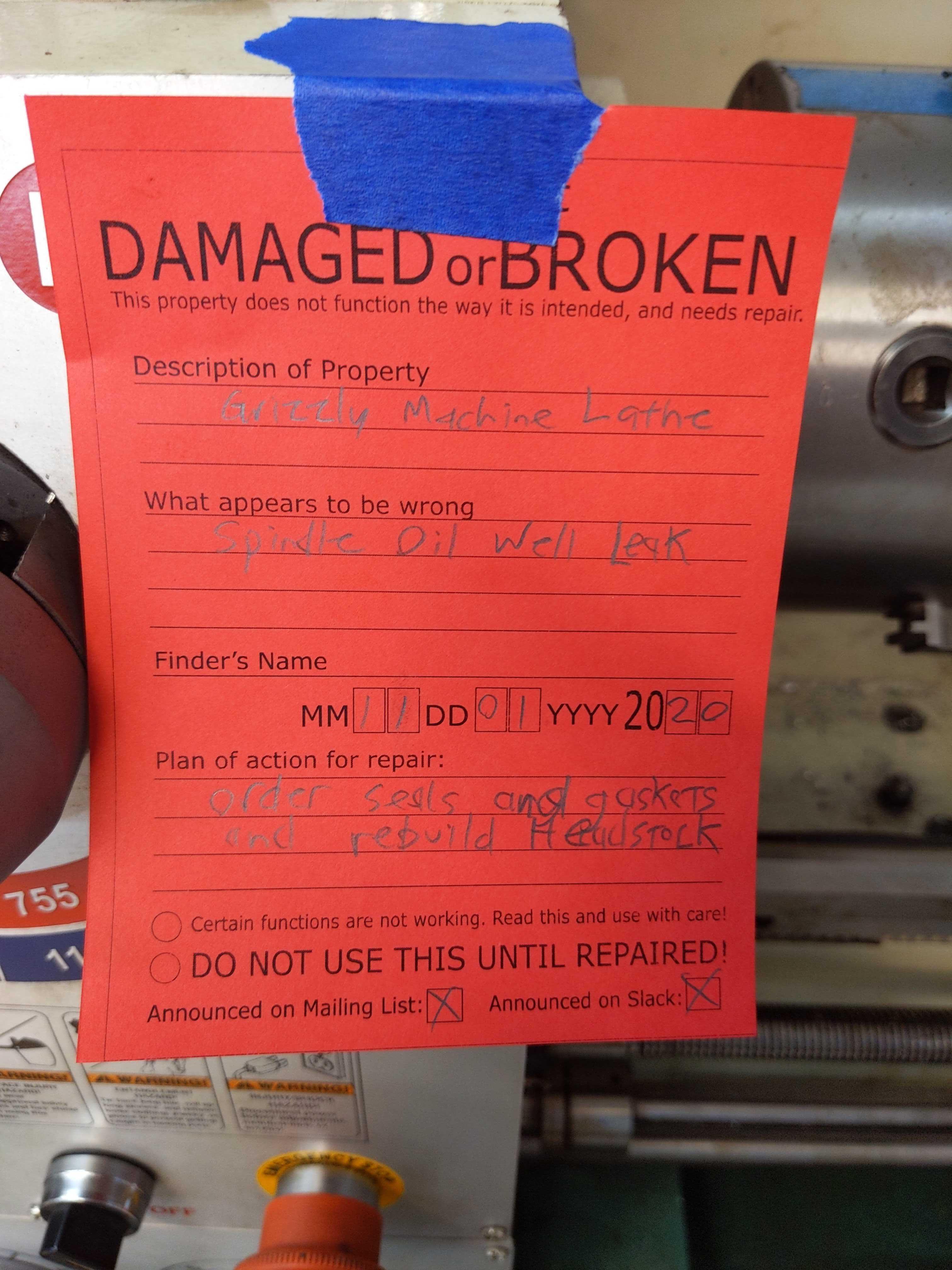

Metal Lathe is Down - Needs Spindle Teardown and Rebuild

20 views

Skip to first unread message

Kevin McLeod

Nov 1, 2020, 2:24:55 PM11/1/20

to Hive13 Makerspace

The Grizzly metal lathe has developed a bad oil leak in the spindle/headstock oil well. We will need to order a seal and gasket kit for it and rebuild the headstock. Please do not use it till that has been done.

If anyone is interested in doing that work, please speak up. It should be pretty satisfying mechanics work for whoever does it. All supplies can be reimbursed from the warden's budget.

Thanks!

Dave Velzy

Nov 1, 2020, 4:27:08 PM11/1/20

to cincihac...@googlegroups.com

The wiki manual shows Headstock parts on page 99 and 100. The oil seals are parts

P07760113, P07760141 and P07760171

There are also o rings P07760102,

P07760126,

P07760141

and

P07760164

After finding an error in the manual re the wrench size for the drain plugs, I'm a little leery about ordering parts without doing a teardown.

I'm going to call Grizzly for more information on Monday.

Dave Velzy

Hive13 Board Member

Hive13 Board Member

--

You received this message because you are subscribed to the Google Groups "Hive13 Makerspace" group.

To unsubscribe from this group and stop receiving emails from it, send an email to cincihackerspa...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/cincihackerspace/d8b7dbad-1fd2-4e09-8940-efd0ab34c558o%40googlegroups.com.

dave....@gmail.com

Nov 2, 2020, 11:55:14 AM11/2/20

to Hive13 Makerspace

So... Grizzly tech said, This isn't a common problem. There are no seals or gasket kits. All parts are in stock but suggested we need to diagnose the problem first. No magic. Just work. I’m going to look closer and try to find the leak path without doing any tear down.

Reply all

Reply to author

Forward

0 new messages