Extrusion issues on DD-Modified CR-6 MAX

115 views

Skip to first unread message

Bane1434

Jun 18, 2021, 8:51:39 PM6/18/21

to 3D Printing Tips and Tricks

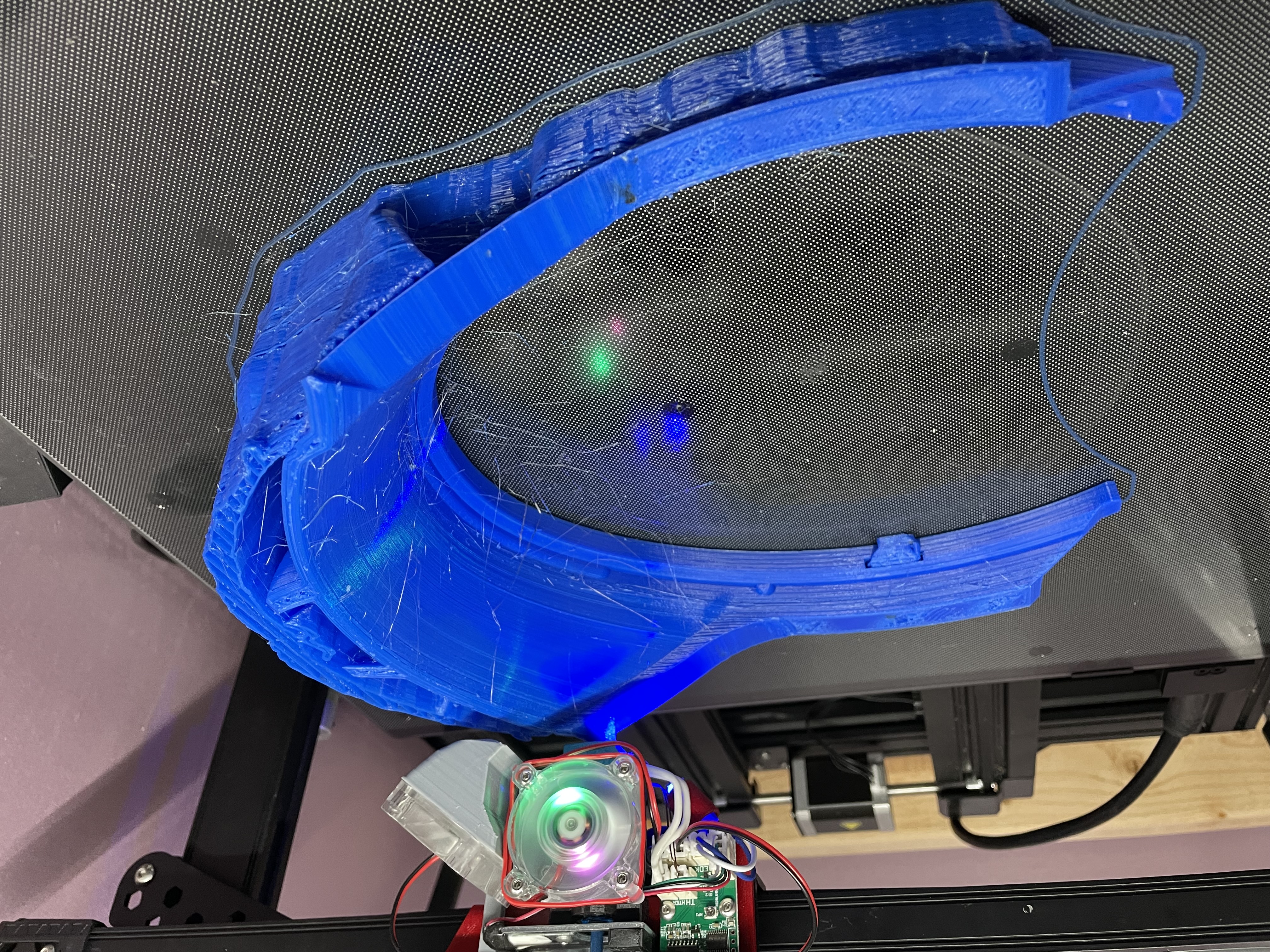

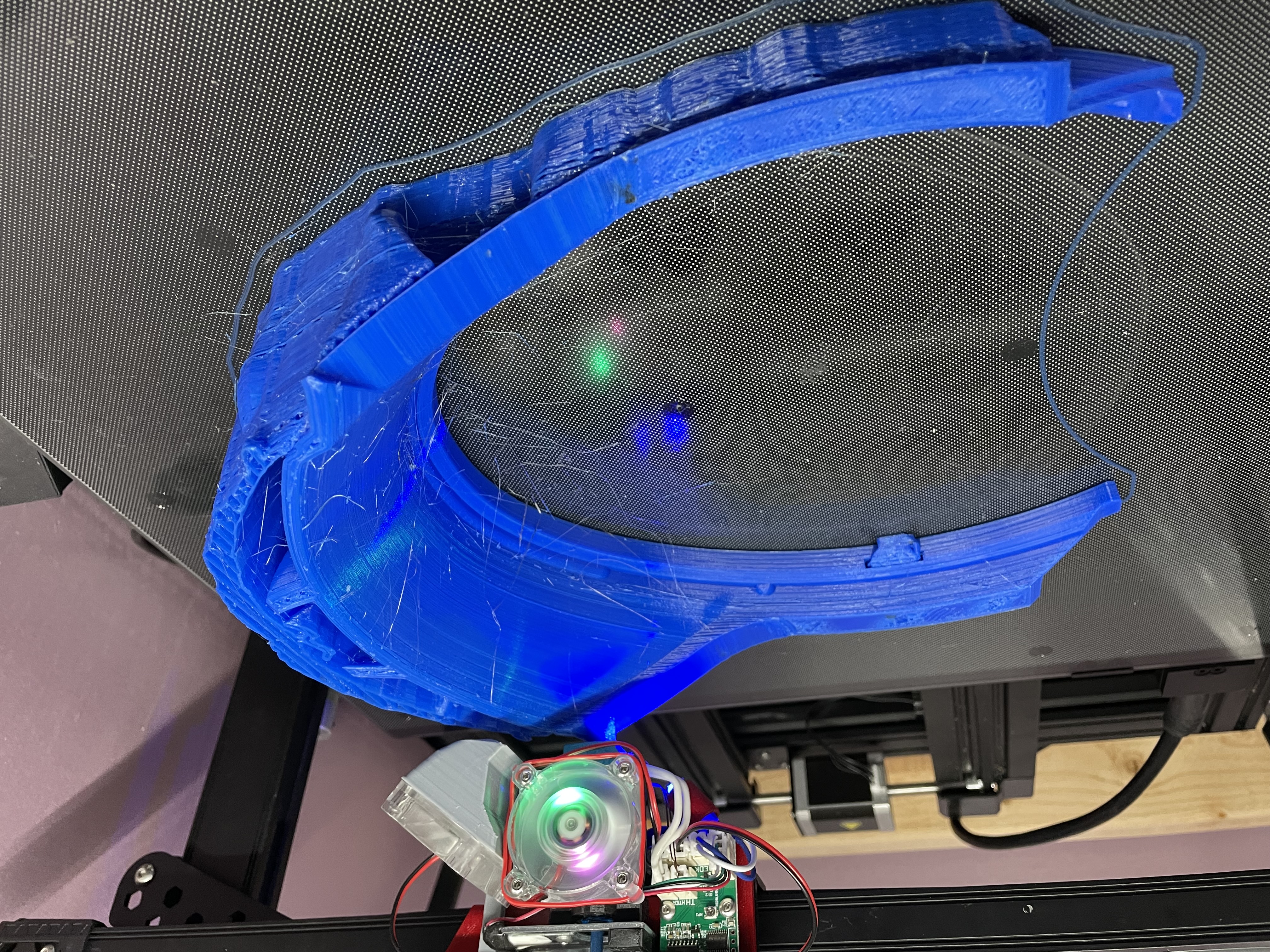

So I recently got my CR-6 Max successfully converted to a direct drive setup. I replaced the stock hot end (after trying several attempts to just replace the ptfe-lined heat break with an all metal one) with and E3D V6 with a mount remix I found on Thingiverse and a DD mount posted on the Creality CR-6 Community Facebook group.

Now that it's June and 100+ degrees I'm wondering if the garage is now TOO hot to print in? I changed out the stock V6 cooler for a 4010 fan thinking this would help in these temperatures, but is this correct? I've noticed issues on my prints where the supports look like they have underextrusion in places, but the print itself seems to still be printing fine. I know normally with PETG, part cooling is unnecessary and not recommended... but should I be using it at these ambient temperatures? Would a bigger or more effective hot end fan (like a noctua 4020) help? My print speed is slow (35mm/s) so I don't think it's a speed issue. Any thoughts or am I just overthinking this?

Kurt at VR-FX

Jun 18, 2021, 11:09:03 PM6/18/21

to 3d-printing-...@googlegroups.com

Wow - you have a LOT of Stringing going on! Dang! But - alas -

that's what I hated about working with PETG previously. To limit

the stringing - you may need to play with temp - or up the

retraction.

As for your Supports looking like SHIT - while the main printed part looks Good - I find that VERY ODD!!! Obviously - supports are with the SAME material. What the heck Slicer are you using? S3D?

It seems quite obvious to me that there are settings that different between your supports and model printing. Maybe you need to get your supports to print with similar parameters. Is there a Temp or Speed diff - between support and model printing??

-K

On 6/18/2021 5:51 PM, Bane1434 wrote:

So I recently got my CR-6 Max successfully converted to a direct drive setup. I replaced the stock hot end (after trying several attempts to just replace the ptfe-lined heat break with an all metal one) with and E3D V6 with a mount remix I found on Thingiverse and a DD mount posted on the Creality CR-6 Community Facebook group.

Now that it's June and 100+ degrees I'm wondering if the garage is now TOO hot to print in? I changed out the stock V6 cooler for a 4010 fan thinking this would help in these temperatures, but is this correct? I've noticed issues on my prints where the supports look like they have underextrusion in places, but the print itself seems to still be printing fine. I know normally with PETG, part cooling is unnecessary and not recommended... but should I be using it at these ambient temperatures? Would a bigger or more effective hot end fan (like a noctua 4020) help? My print speed is slow (35mm/s) so I don't think it's a speed issue. Any thoughts or am I just overthinking this?

--

You received this message because you are subscribed to the Google Groups "3D Printing Tips and Tricks" group.

To unsubscribe from this group and stop receiving emails from it, send an email to 3d-printing-tips--...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/3d-printing-tips--tricks/3fe18377-b9f7-49aa-9960-c90b716332f8n%40googlegroups.com.

TobyCWood

Jun 19, 2021, 12:16:18 PM6/19/21

to 3D Printing Tips and Tricks

Who said part cooling in PETG is not recommended? If that was from a Youtuber, I suggest not watching them anymore. I always have my downward fans on minimal for PETG as I do for ABS. The only time I have downward cooling off is for Nylon, PC or when I need the part to fuse layers the most I can get it (which assumes long tool paths so the extrusions cool on their own before the hotend passes again).

What temp is the extruder? I always start at 230C for PETG but on average I get the best results at 235C. PETG, like TPU, bubbles at hotter temps.

PETG is notorious for super fine stringing. Even after you solve the overt stringing the faint wisps may still be there and instead of stretching between retractions they slowly pile up into an ugly booger which randomly falls into the object you are printing. It depends upon the PETG. Some are better than others.

Is it too hot to print? Very possibly! When it gets that hot I avoid running any machines simply because the power may go out in the middle of a long print.

Is it too hot to print? Very possibly! When it gets that hot I avoid running any machines simply because the power may go out in the middle of a long print.

TobyCWood

Jun 19, 2021, 12:22:41 PM6/19/21

to 3D Printing Tips and Tricks

Oh yeah... "downward fans on minimal"...

Some fans can go slower than others. Typically a downward fan needs adequate CFM and a 4010 box fan is not the optimal solution for that. The 5015 squirrel cage fan is the go to for downward cooling since it can compress and move the air at a higher CFM. However, these fans can have a higher minimal speed. It depends on the fan, the PWM capability of your controller and the age of the fan. You'll need to test to see just how slow it can go without stalling.

Bane1434

Jun 20, 2021, 12:48:43 PM6/20/21

to 3D Printing Tips and Tricks

Thanks for the feedback from both of you. The 5015 fan input is much appreciated. I was looking for some sort of cooling solution that already existed on thingiverse which is why I went with the 4010, but it really doesn't fit my use case with the V6. It blows on the heater block and not under it. The Stock fan on the CR-6 Max is the 4010 squirrel cage fan. I know on my Ender 3, any speeds below 50% didn't seem to be enough power to engage the fan after the inital zero fan first layer. I've got PETG printing pretty dialed in on my Ender 3, but it's in an enclosure in my home, and the smaller heated build plate won't put out so much heat in that environment where it it causes issues, compared to the 400x400 bed heater or the poorly insulated garage environment. I definitely need to run some smaller test pieces before I start another large print (which did finish). Excitement in that I actually got it printing overtook my need to finish the configurating process.

I wish I had waited a couple more months before I bought my Bondtech BMG extruder. I see Bondtech just put out an LGX solution for the CR-6 that looks like a really slick, elegant solution. Knowing me I'll probably end up getting it... just because I can't stop throwing money at my only current hobby.

https://www.bondtech.se/2021/05/17/how-to-install-a-lgx-on-the-cr-6-se/

https://www.bondtech.se/2021/05/17/how-to-install-a-lgx-on-the-cr-6-se/

Reply all

Reply to author

Forward

0 new messages