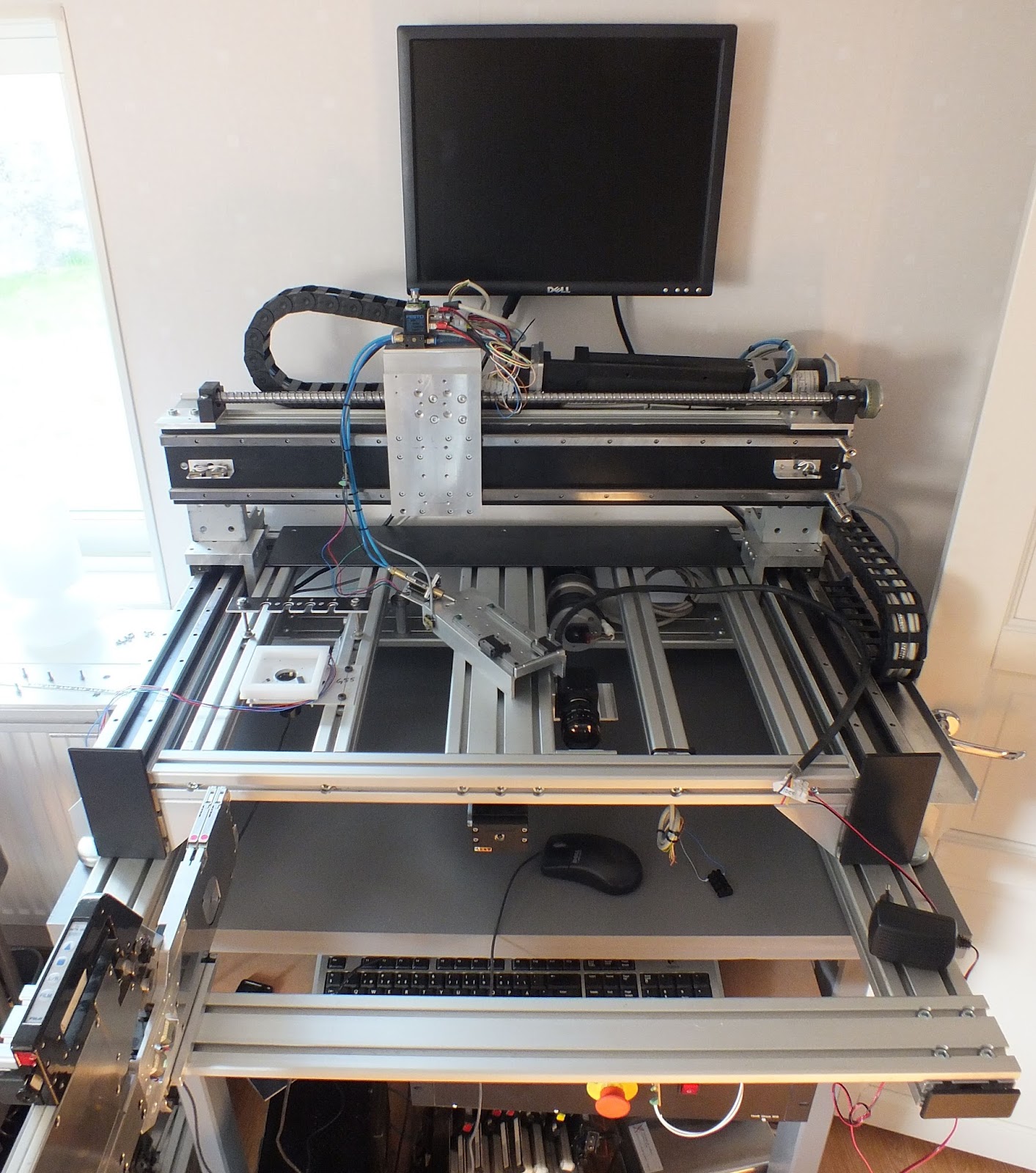

Henriks machine, general presentation.

Henrik

Mark Harris

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/ab25a10b-93e9-4bc6-8514-31db2f5b5fdc%40googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

Jason von Nieda

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAJMBTyQ8UjtKGdspjgRiHMN_fOZjus7pS%3DP5RYV7Y2vmbaDQEA%40mail.gmail.com.

Rich Obermeyer

Henrik

Thanks Mark!

Henrik

Thanks Jason,

Cri S

Henrik Olsson

What is your plan for rs485. Using analog MUX 32 or having external pin for location resolving of feeder.

--You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/868e34bd-6d20-4178-a1e6-4c12bacb5167%40googlegroups.com.

Cri S

You don't have understand me.

Normally exchangeable feeders need a way of localisation of where feeder is placed inside machine. Sure, you can decide to not allow loading and unloading the feeders and screw it directly on the table.

I have seen feeders that read out i2c memory. Without external eeprom there don't work.

> To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/1459341892927.99676.6974%40webmail7.

>

> For more opt

Jason von Nieda

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/1459341892927.99676.6974%40webmail7.

Henrik Olsson

Cri S,

OK, now I understand what you mean.

The feeders will be removable from the machine but at this point they will have to be placed back in the same location.

Currently, each feeder has a hardcoded ID (I could make it changeable but I currently don’t see the need for that). You could have a table in openPNP so that you could map feeder slots (pickup locations) to actual feeder ID but for me it would be enough to just be able to send a command down the bus.

I don’t see how I could randomly move feeders around and automagically have openPNP determine in which physical “slot” each feeder is – not with what I have now at least. An alternative is to build a single device with a serial port and whole bunch of discrete I/Os. That way each physical slot on the machine will have its own dedicated signal lines for feeder action and the actual feeders can go anywhere. Still need the serial though….but I see Jason has some ideas about that which I’ll read, dwell on and comment shortly.

/Henrik.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAJGcfUiegO7zCQ3hd6yyYvb%2Bsrwup%3D004qXKsx1%2BGfdgenSkvg%40mail.gmail.com.

Mike Harrison

>Cri S,

>

>OK, now I understand what you mean.

>

>

>

>The feeders will be removable from the machine but at this point they will

>have to be placed back in the same location.

>

>

>

>Currently, each feeder has a hardcoded ID (I could make it changeable but I

>currently don’t see the need for that). You could have a table in openPNP so

>that you could map feeder slots (pickup locations) to actual feeder ID but

>for me it would be enough to just be able to send a command down the bus.

>

>

>

>I don’t see how I could randomly move feeders around and automagically have

>openPNP determine in which physical “slot” each feeder is – not with what I

>have now at least. An alternative is to build a single device with a serial

>port and whole bunch of discrete I/Os. That way each physical slot on the

>machine will have its own dedicated signal lines for feeder action and the

>actual feeders can go anywhere. Still need the serial though….but I see

>Jason has some ideas about that which I’ll read, dwell on and comment

>shortly.

feeder doesn't really matter - you probably need it as a way to talk to individual feeders on a

common bus, but that;s it. What matters is what parts it has loaded ( and maybe how many are left),

and where it is physically located at present. And maybe some generic feeder-type info ( e.g. how

long it takes to index, vib/tape/passive etc. )

When you initially set up a job and load parts into feeders, you want to say "feeder in position

<x>, you have 3000 of part 15k_0805", which is stored in an eeprom in the feeder.

When you run the job, it looks for feeders that contain each of the required parts and builds a

table of their physical position.

Of course you need a way to determine the phyisical position of each feeder.

An idea to make this work with all feeders on a common bus, avoiding the need for location-specific

connections etc. :

Each feeder has a switch or sensor that can somehow be actuated by the head.

When feeders are fitted, the head then goes and operates the sensor in each feeder position in turn,

and the feeder that senses the head shouts "Hey that's me", and sends its stored component data.

This idea could also avoid the need for a hardcoded feeder ID for bus addressing - once a feeder has

been detected, the system then tells the feeder its physical position for future addressing ( or

assigns it a bus-unique ID).

Another approach is to have globally unique feeder IDs for bus addressing, and it does an initial

poll to see who;s present, and asks the user where each one is located.

.

obiwanke...@gmail.com

From the feeder thread, it looks like some of the smart feeders being designed would each individually be addressed by RS485 to advance, possibly a modbus command of how far to advance, and some feeders will be addressed by a controller that sets a I/O for each feeder in its group.

Henrik Olsson

Those are of course all excellent suggestions and ideas but for me,

personally and at this time, I don't see a need for openPNP automatically

tracking my feeders around. It would be nice and cool and all that but I

think it would involve a lot of development.

Since I'm more or less relying on Jasons good will to get me off the ground

here I'd personally settle for a way to send a serial command out and

possibly wait for a reply saying "Here you are sir, your part is served" or

"Sorry sir it appears I'm out of that one".

I've thought of the head operated sensor idea as a way to avoid having the

RS485 bus or discrete signals but it's another workaround IMO. I know that's

not what you're suggesting though.

The global addressing and having the user tell the software where each one

is located is probably the easiest to develop. You can have a table which

you can edit manually or openPNP can send a specific command that tells the

feeder with that ID to flash its LED or whatever and then ask the user in

which slot that feeder is.

But again, for me personally, I'd be happy to just have a simple way of

sending something out a serial port, and possibly waiting for a response.

But, if Jason decides to do something fancy I can adapt the code in my

feeders :-)

/Henrik.

You received this message because you are subscribed to a topic in the

Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit

https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

To unsubscribe from this group and all its topics, send an email to

openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit

%404ax.com.

Rich Obermeyer

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/1459341892927.99676.6974%40webmail7.

obiwanke...@gmail.com

http://www.modbustools.com/modbus.html

Cri S

use Modbus ASCII for parsing it on Com port.

Every memory collection on java scream you'r software timed RTU

communication up if

happens during transmission or if some asynchron event need be served

by the java code.

ASCII Modbus works fine, always.

2016-03-30 17:56 GMT, obiwanke...@gmail.com <obiwanke...@gmail.com>:

> own. PLC's and other off the shelf hardware use Modbus, there's probably an

>

> open source library that can be pulled into OpenPnP. For slave hardware

> Raspberry Pi and Arduino have libraries available. Packet size can be

> fairly large, 10 data fields would probably work ?

> http://www.modbustools.com/modbus.html

>

>

> On Wednesday, March 30, 2016 at 11:26:34 AM UTC-6, Maddog wrote:

>>

>> @henrik, i think you got the right ideas here. I previously did a vending

>>

>> machine using RS485 and this is vary close to the same thing. Tell some

>> remote mechanical sub assembly to spit out something of various size and

>> shape and tell me when your done through a poll.

>>

>> I would think the command string should have feeder ID, sub feeder,

>> command byte, command parameter and then checksum to protect from errors

>> causing issues later.

>> Sub feeder lets you use same circuit for many feeders.

>> You could have 255 feeders, 255 sub feeders, 255 commands to those feeders

>>

>> with an 8 bit parameter. That should cover all the potential uses.

>> Send 0500010107cr, feeder 5, sub 0, led command, light on, checksum,

>> carriage return.

>> Send 0501030817cr, feeder 5, sub 1, index, 8, checksum, cr.

>> Any command set is possible.

>>

>> How are you setting the feeder ID on your current board?

>>

>> On Mar 30, 2016, at 5:44 AM, Henrik Olsson <hen...@henriksplace.se

>> >:

>> What is your plan for rs485. Using analog MUX 32 or having external pin

>> for location resolving of feeder.

>>

>> --

>> You received this message because you are subscribed to a topic in the

>> Google Groups "OpenPnP" group.

>> To unsubscribe from this topic, visit

>> https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

>> To unsubscribe from this group and all its topics, send an email to

>> .

>> https://groups.google.com/d/msgid/openpnp/868e34bd-6d20-4178-a1e6-4c12bacb5167%40googlegroups.com.

>> For more options, visit https://groups.google.com/d/optout.

>>

>>

>> --

>> You received this message because you are subscribed to the Google Groups

>>

>> "OpenPnP" group.

>> To unsubscribe from this group and stop receiving emails from it, send an

>>

>> .

>>

>> <https://groups.google.com/d/msgid/openpnp/1459341892927.99676.6974%40webmail7?utm_medium=email&utm_source=footer>

>> .

> Google Groups "OpenPnP" group.

> To unsubscribe from this topic, visit

> https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

> To unsubscribe from this group and all its topics, send an email to

> openpnp+u...@googlegroups.com.

> To post to this group, send email to ope...@googlegroups.com.

> To view this discussion on the web visit

Rich Obermeyer

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/10bc7931-ffdc-4513-a942-2d9aee5737d1%40googlegroups.com.

Mike Harrison

>MODBUS is rather overkill for a simple feeder network.

>None of the existing commands relate to a feeder so you would have to roll

>your own command set anyway.

>Feeders typically have sub feeders to reduce electronics. Modbus does not

>handle that case.

>Running a rasberry Pi as a modbus feeder controller seems like a V8 on a

>go-kart to me.

>The existing controller is a trivial PIC processor.

Unless there are existing bits of Modbus hardware that you want to interface, there's no need for

anything as complex, and no need to pull in and learn someone's library to deal with it.

As you'll be so far inside RS485 cable length and speed specs you won't ever see data errors so

checksums wouldn't be necessary. (some may disgree but my experience doing megabaud over tens of

metres of cat5 tells me that a few hundred kbaud over a few metres is just going to work 100%)

With an ASCII protocol, simply filtering on character range and message length would be more than

enough.

If in doubt, keep it simple! Resources are always finite, so building a belt-and-braces system just

isn't justifiable.

Henrik Olsson

I’m using an 8bit PIC as the controller in the feeders and although I’ve written my own MODBUS stack (RTU) for that family I agree with Chris, it’s overkill and not really suited. If it was already built into openPNP and was ready to use I could certainly adapt but I don’t think we should go in that direction.

My current 6 byte ASCII protocol as simple as it is works fine, it doesn’t have an actual checksum or CRC but it still verifies that the first part (005 for feeder 5) matcher the second part (250 for feeder 5). But then again, that’s just me, others might want it different and I can adapt at my end.

/Henrik.

Från:

ope...@googlegroups.com [mailto:ope...@googlegroups.com] För Rich Obermeyer

Skickat: den 30 mars 2016 20:27

Till: ope...@googlegroups.com

Ämne: Re: [OpenPnP] Re: Henriks

machine, general presentation.

MODBUS is rather overkill for a simple feeder network.

Henrik Olsson

Sorry, I meant to say I agree with Rich, got the names mixed up….

Från:

ope...@googlegroups.com [mailto:ope...@googlegroups.com] För Henrik Olsson

Skickat: den 30 mars 2016 20:49

Till: ope...@googlegroups.com

Ämne: [OpenPnP] Re: Henriks

machine, general presentation.

I’m using an 8bit PIC as the controller in the feeders and although I’ve written my own MODBUS stack (RTU) for that family I agree with Chris, it’s overkill and not really suited. If it was already built into openPNP and was ready to use I could certainly adapt but I don’t think we should go in that direction.

My current 6 byte ASCII protocol as simple as it is works fine, it doesn’t have an actual checksum or CRC but it still verifies that the first part (005 for feeder 5) matcher the second part (250 for feeder 5). But then again, that’s just me, others might want it different and I can adapt at my end.

/Henrik.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

Mike Harrison

>None of the existing commands relate to a feeder so you would have to roll

>your own command set anyway.

>Feeders typically have sub feeders to reduce electronics. Modbus does not

>handle that case.

>Running a rasberry Pi as a modbus feeder controller seems like a V8 on a

>go-kart to me.

predictable for a given type, I think simply being able to tell the system how long a feed will take

(baseline <t1> plus <t2> * number of indexes) is simpler than doing 2-way comms to find when a feed

is complete.

Especially when you consider issues like whether you feed before or after a pick, as in the former

case (e.g to keep maximum cover tape in pace and reduce risk of bounce-out from vibration) you want

to overlap the feed time with time to get the head to the feeder, but need to know that the feeder

is ready before picking. This could get quite messy with a polled system, but very easy with simple

timings.

One thing the RV does, which I don't think actually gives much benefit, is for multiple indexes, it

does one index after pick, and the rest after recognition. The logic being that it will

automatically get itself in sync by feeding one index at a time until you get a good pick.

As it does all the remaining indexes before placing, it actually slows things down ( though this is

a limitation of their implementation, not the general principle)

The only situation where it might make sense is if you have a flaky feeder that sometimes misses

single indexes, so it gets itself back in step. But better to make the feeders more reliable!

Rich Obermeyer

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/cl7ofbpqgenhftnu1gvbvellqb2srusm74%404ax.com.

For more options, visit https://groups.google.com/d/optout.

obiwanke...@gmail.com

Is this bus just feeders, or any external device not controlled by the motor controller ? If it's just a simple feeder control then an ASCII string with CRC would work fine, or could it one day include a conveyor system that could stretch out ~20 feet, tied into stencil printer, etc. ?

Mike Harrison

>Not seeing how polling for a feeder (micro seconds) complete on RS485 could

>add any significant delay to the process that's seconds already. What else

>is going on while you are waiting for a feeder to advance?

minimal, once they go through a USB-485 converter, especially a cheap one that is full speed, not

high speed, and if its timeouts haven't been optimised, turnround times can get surprisingly high -

well into many tens of mS per transaction.

If your feeders like to keep the cover tapes on, you want to be moving towards the feeder, but want

to make sure the feed is done before picking.

Less of an issue where you feed immediately after pick.

>This loop would simplify the driver process as well.

sending a feed command, it will be ready.

As soon as you have 2-way comms, you have to think how to deal sensibly with getting the reply, and

deciding what to do if you don't, all while you're doing other things like moving teh head or maybe

changing a nozzle en route.

And testing that code under enough conditions to be confident that it works.

>Assuming advance times is poor assumption when you consider all the tape

>sizes. Requiring the user to input the delay is just more useless homework

>per feeder during setup.

Yes in an ideal world everything would run on highly flexible protocols over fibre with error

correction, but in the real world we just want to get something that works, and not be any more

complicated/time consuming to implement than it needs to be.

Cri S

feed at rate of 40-46ms interval.

The feed command need to be issued after picking the component, now if you have

two nozzles and distance is 40mm from idling point to the picking

point for the second nozzle,

it need (using 16 spocket without reduction) 208 ms to get to the pick

up position using

trapez acceleration, using jerk limited acceleration it need more time.

Now if delay is 150ms, who cares, it don't change anything.

2016-03-30 19:42 GMT, Mike Harrison <mi...@whitewing.co.uk>:

> You received this message because you are subscribed to a topic in the

> Google Groups "OpenPnP" group.

> To unsubscribe from this topic, visit

> https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

> To unsubscribe from this group and all its topics, send an email to

> To post to this group, send email to ope...@googlegroups.com.

> To view this discussion on the web visit

Cri S

over 512 feeder.

The microcontroller need only to have circular buffer of 7 bytes and

compare it with the

(2-8) precomputed modbus messages, no need for crc calc.

0x01, 0x05, 0x02, 0x00, 0x00, 0x00, 0x00

byte 3 and 4 contains the id value and 5 and 6 the offline computed

crc checksum.

It works too if ignoring the crc and checking only 5 bytes.

No need for checking timeout or other things. and if there is positive

match, the array need

to be erased, or at least the second byte set to zero.

Now there are 655 valids id, if every feeder have 4 id, for

(led-)on/off/blink/feed , there

could be 163 configured feeder, reserving 7 for tray 7-pos tray

changer there could be 162

feed lanes. Maybe it's better to add more codes for leds add if

allowing 6 codes / lane,

it's possible to have 102 feeder lane (dual feeder = two lanes) and 8

pos tray changer.

2016-03-30 20:00 GMT, Cri S <phon...@gmail.com>:

Henrik Olsson

Jason,

I’ve read your post a couple of times now and in general I think it looks good. How flexible it becomes obviously depends on how the variable substitution works, what you allow access to, if static “text” can be included and how you “build” or “format” what actually goes out.

So, an actuator is always associated with a G-code while a feeder necessarily isn’t and that’s why we’d have to define one actuator and one feeder – for each feeder – in order for the subdriver to have something to act on in order to have it send the data our? It seems a bit convoluted but totally workable but why not include it directly in the AutoFeeder? Would doing that make it less flexible?

I’m sorry if this is obvious to people used to the internals of openPNP.

Why the double precision number and how exactly would it be sent, as the 8 byte binary it actually is or converted to ASCII and if ASCII would it always have the same number of characters?

By the way, how does one actually add or create a nozzle or an actuator in the Machine Setup tab? I can’t seem to do anything…

/Henrik.

Michael Anton

Michael Anton

Jason von Nieda

I’ve read your post a couple of times now and in general I think it looks good. How flexible it becomes obviously depends on how the variable substitution works, what you allow access to, if static “text” can be included and how you “build” or “format” what actually goes out.

So, an actuator is always associated with a G-code while a feeder necessarily isn’t and that’s why we’d have to define one actuator and one feeder – for each feeder – in order for the subdriver to have something to act on in order to have it send the data our? It seems a bit convoluted but totally workable but why not include it directly in the AutoFeeder? Would doing that make it less flexible?

Why the double precision number and how exactly would it be sent, as the 8 byte binary it actually is or converted to ASCII and if ASCII would it always have the same number of characters?

By the way, how does one actually add or create a nozzle or an actuator in the Machine Setup tab? I can’t seem to do anything…

Henrik

Jason, while playing around with the configuration files I managed to add a second nozzle and additional nozzle tips by editing the Machine.xml file. However I failed to add an actuator which is not part of the head. I tried twice and openPNP refused to start since I apparently corrupted the file. There doesn't seem to be a non head referenced actuator in there so the format isn't that clear to me. I'll need to play more with that.

The more I read and think about your suggested approach with the sub-driver the more sense it makes and if you get that into openPNP I can certainly make it work at my end and there's nothing preventing people from building conveyors and what not. It probably won't be easy to adapt to existing stuff with various protocols though.

Jason von Nieda

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/5691f628-fe5c-4084-9347-e2c52d35f351%40googlegroups.com.

Jason von Nieda

Henrik Olsson

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CA%2BQw0jw%3Duze9oz7Ez3OzWwr8dh8nCtqz5OdAwsbEdK8jtgUfCA%40mail.gmail.com.

Jason von Nieda

I managed to add the actuator part to the machine.xml file and have it show up in the tree-view in OpenPnP but there's nothing to configure on the right hand side - which sort of makes sense since a non head mounted actuator won't have a safe Z or offset would it? But why should the data then be included in the configuration?

Still so much to learn....I see you're making great progress on the new driver, I'll read thru the other thread and possibly comment there. Could you quickly run thru, or point me to a tutorial on how I'd go about to "pull it into" Eclipse - that's (also) totally new teritory for me :-(

It appears as if the Swedish post have lost my Smoothieboard. I have a tracking number but they don't know where it is. Took three days from France to Sweden and now 9 days here.

Henrik Olsson

--You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CA%2BQw0jwghOEqrqq2gMTzvXCEmUNmJU55AZyD3hjKr3D2y5g-gw%40mail.gmail.com.

Henrik

Anthony Webb

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/4eac75ed-d079-4d33-94c3-9749b5cabb06%40googlegroups.com.

matt

invention? Guessing driving the left one down lifts the right one and

vica versa? Simples!

On 2016-05-25 19:14, Anthony Webb wrote:

> Thanks for sharing! Keep the updates coming, you're doing some nice

> work!

>

> On Wed, May 25, 2016 at 12:06 PM, Henrik <hen...@henriksplace.se>

> wrote:

>

>> I thought I'd share a bit of what I've been doing the last couple of

>> weeks.

>> I ordered a couple of different CCTV lenses to try on the head

>> mounted camera, I think I've settled on using a 12mm F1.2, made a

>> ring-light of it from one the cheap angle-eye LED rings and a couple

>> of pieces of white plexi:

>>

>>

>> [2]

>> In the end I don't know.... even at very low current there's a clear

>> reflection, like a halo, in the image from the camera. I don't Think

>> it'll matter for finding fiducials though, will have to wait and

>> see.

>>

>> Bottom vision is using a monochrome Pulnix TM6 camera and I'm using

>> a cheap USB capture dongle to grab the images. The camera is mounted

>> parallell with the bed of the machine is looking into a 45° first

>> surface mirror and up thru a mock-up of the illumination:

>> Just some White LED strip at an angle but the I have big hope on

>> that the images produced by this setup will work fine with the

>> vision pipeline in OpenPNP. If you're reading this Jason I'd

>> appreciate a comment on if you Think this is workable or if I should

>> throw it out and get an ELP like everybody else :-)

>>

>> 4 nozzles in one image)

>>

>> The head rebuild is mechanically complete. Two Samsung CPP45 style

>> nozzles on NEMA 8 motors. One of the motors had a badly bent shaft

>> but I managed to straighten it. The "nozzle adapters" are just some

>> PCB spacers drilled and reamed too which I've then epoxy glued the

>> actual nozzle holders. This allowed me dial in the runout of the

>> holder quite good. That doesn't mean the nozzles run 100% true

>> though.

>>

>> Now I'll get back to playing around with the Smoothie and thinking

>> about the issue with the feeder rack while I'm waiting for the bare

>> PCBs to show up - which will take a couple of weeks.

>>

>> /Henrik.

>>

>>>

>>

>> --

>> You received this message because you are subscribed to the Google

>> Groups "OpenPnP" group.

>> To unsubscribe from this group and stop receiving emails from it,

>> send an email to openpnp+u...@googlegroups.com.

>> To post to this group, send email to ope...@googlegroups.com.

>> To view this discussion on the web visit

>>

> https://groups.google.com/d/msgid/openpnp/4eac75ed-d079-4d33-94c3-9749b5cabb06%40googlegroups.com

>> For more options, visit https://groups.google.com/d/optout [8].

> --

> You received this message because you are subscribed to the Google

> Groups "OpenPnP" group.

> To unsubscribe from this group and stop receiving emails from it,

> send an email to openpnp+u...@googlegroups.com.

> To post to this group, send email to ope...@googlegroups.com.

> To view this discussion on the web visit

> [9].

> For more options, visit https://groups.google.com/d/optout [8].

>

>

> Links:

> ------

> [1]

> https://lh3.googleusercontent.com/-B6EUK6XWN_o/V0XgwJllj3I/AAAAAAAAADQ/mQC5DLRUowA17_oZu-R6YcAN9izVj25bACLcB/s1600/Ring%2Blight%2B-%2B1.jpg

> [2]

> https://lh3.googleusercontent.com/-ByA2bBS-rI8/V0Xg6CLH6mI/AAAAAAAAADU/5ITkY-fJ7IkN6yUp9SsmVSzX6ADYfwesgCLcB/s1600/Ring%2Blight%2B-%2B2.jpg

> [3]

> https://lh3.googleusercontent.com/-hgscKQMeZtQ/V0Xh876CfhI/AAAAAAAAADk/Yj9VsiZyqI8fK9fwlT98ILjvq6L44zJ-gCLcB/s1600/Bottom%2Bcamera.jpg

> [4]

> https://lh3.googleusercontent.com/-DTuVqKk62_o/V0XitG12dEI/AAAAAAAAADs/RXBz_rvORQcbzvMw7aDeMkGxlTE0p_xgwCLcB/s1600/Sample%2Bimages.png

> [5]

> https://lh3.googleusercontent.com/-nGNYX4awjK0/V0Xj72usuPI/AAAAAAAAAD4/EPuwbSCIO3IAU_RR04w06JWwmafxgftwgCLcB/s1600/New%2Bhead%2B-%2B1.jpg

> [6]

> https://lh3.googleusercontent.com/-jBBQP_QxPk0/V0Xnm8GptbI/AAAAAAAAAEE/ROpQUpOBVJcXPzgeYzcAnjr7u8qDlNumgCLcB/s1600/Feeder%2Brack%2B-%2B2.jpg

> [7]

> https://groups.google.com/d/msgid/openpnp/4eac75ed-d079-4d33-94c3-9749b5cabb06%40googlegroups.com?utm_medium=email&utm_source=footer

> [8] https://groups.google.com/d/optout

> [9]

> https://groups.google.com/d/msgid/openpnp/CALsNZy19_uWjtw_KaqnPf5ZNfOCjyYq-1JqHfuTJSZ-Lc8U9RA%40mail.gmail.com?utm_medium=email&utm_source=footer

Henrik Olsson

are the same on both sides it's sort of balanced reducing the load on the

motor.

Nope, can't take credit for that idea. I first saw it used on the SmallSMT

machines.

/Henrik.

-----Ursprungligt meddelande-----

Från: ope...@googlegroups.com [mailto:ope...@googlegroups.com] För matt

Skickat: den 25 maj 2016 21:38

Anthony Webb

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/8836F82EC78B477A9A847DE9E81154D9%40Office.

For more options, visit https://groups.google.com/d/optout.

matt

How well does this head design work in practise? Any videos?

Thanks

Matt

>>

>> For more options, visit https://groups.google.com/d/optout [2].

> --

> You received this message because you are subscribed to the Google

> Groups "OpenPnP" group.

> To unsubscribe from this group and stop receiving emails from it,

> send an email to openpnp+u...@googlegroups.com.

> To post to this group, send email to ope...@googlegroups.com.

> To view this discussion on the web visit

> [3].

> For more options, visit https://groups.google.com/d/optout [2].

>

>

> Links:

> ------

> [1]

> https://groups.google.com/d/msgid/openpnp/8836F82EC78B477A9A847DE9E81154D9%40Office

> [2] https://groups.google.com/d/optout

> [3]

> https://groups.google.com/d/msgid/openpnp/CALsNZy33HRo2gOJ9Cgz9PkWCUpFjuszODohE_Usu9HWPogOrVA%40mail.gmail.com?utm_medium=email&utm_source=footer

Henrik Olsson

have a look. Here's one example where they're changing nozzles as well:

https://www.youtube.com/watch?v=5NNG4zVMPWg

If you mean my version of the design then I don't know yet. Haven't powered

it up yet....

/Henrik.

-----Ursprungligt meddelande-----

Från: ope...@googlegroups.com [mailto:ope...@googlegroups.com] För matt

Till: ope...@googlegroups.com

Kopia: Anthony Webb

Andrew Frazer

Jason von Nieda

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/4eac75ed-d079-4d33-94c3-9749b5cabb06%40googlegroups.com.

For more options, visit https://groups.google.com/d/optout.

Henrik Olsson

Glen English

cheap and easy MCU implementation.

Henrik Olsson

Michael Anton

Andrew Frazer

Henrik

Glen English

I'd accept ASCII control if :

1) it is properly escaped and char stuffed.

Mark Harris

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/472cdc36-8771-4c82-ae8f-6bf8b3db0f2c%40googlegroups.com.

Glen English

Henrik

Finally got the new head connected for some initial tests. Motion is nice, smooth and, I think, fast enough. I've uploaded a clip here:

Jason von Nieda

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/b39a690f-577b-4728-9e90-e913cca4f1c7%40googlegroups.com.

mojalovaa1

Henrik

Thanks Jason,

I didn’t shoot for anything in particular with the Z-axis speed – except ”not slow”. I think I managed that.

The acceleration is 2.2G, I wonder if the part will fall off the nozzle….

Unfortunately X/Y, being on ballscrews, is not nearly as fast. Currently they’re set to 15m/min (and 0.1G acceleration) but will theoretically do 20 if pushed to the max. I’m shopping around for 20mm pitch screws in order to double that speed but at the moment I need (really trying to convince myself) to focus on getting what I have working instead of the endless “upgrade loop” I’ve seemed to put myself in J

/Henrik.

Henrik Olsson

Hi,

If you mean driver for the stepper motor then it’s a 2M982.

If that’s not what you’re asking please elaborate and I’ll do my best to answer.

/Henrik.

--

You received this message because you are subscribed to a topic in the Google

Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/13a55817-69dc-4d84-8c20-6f575d9c96a9%40googlegroups.com.

mojalovaa1

Henrik Olsson

Ah, I’ll not be using that. I initially started with the intention of using dragfeeding, you can see of video of it here: https://www.youtube.com/watch?v=aOxhEA7rVYg but I never came to terms with it how to handle the cover tape and the possibility of the pick position drifting so for the common parts I’ll be using the motorized feeders you see in the beginning of the thread, then I’ll be using various trays and strips. At least that’s the plan.

/Henrik.

--

You received this message because you are subscribed to a topic in the Google

Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/ef4dfdb9-d164-41a1-800a-c59293c1ae03%40googlegroups.com.

mojalovaa1

About automatic feeder , that is not cheap options , I m plane design some cheap feeder but on other side need be 100% precise for use , before I m use this feeder : https://www.youtube.com/watch?v=4fr3bUYexXc , then after I m make drag feeder but on this moment I think that I will design something new for my new machine .

Henrik Olsson

It was a small BOSCH pneumatic cylinder.

Automatic feeders aren’t the cheapest option for sure. But now there are the Yamaha feeders on AliExpress which I think is reasonably priced and apparently you can cut deals with the seller(s) when buying multiple – which you would do. Still going to cost a fair bit of change of course.

/Henrik.

Från: ope...@googlegroups.com [mailto:ope...@googlegroups.com] För mojalovaa1

Skickat: den 19 juni 2016 21:56

Till: OpenPnP

Ämne: Re: [OpenPnP] Re: Henriks

machine, general presentation.

I see that you not have cover puller , but for me is interested what you are use for actuator , that is pneumatic or electromagnetic actuator ?

About automatic feeder , that is not cheap options , I m plane design some

cheap feeder but on other side need be 100% precise for use , before

I m use this feeder : https://www.youtube.com/watch?v=4fr3bUYexXc

, then after I m make drag feeder but on this moment I think that I

will design something new for my new machine .

--

You received this message because you are subscribed to a topic in the Google

Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/256c5806-d596-44a2-a3d4-a544e80c4445%40googlegroups.com.

mojalovaa1

Mark Harris

I m buy now this stepper driver for x and y axis , I hope so that will be ok : http://www.ebay.com/itm/191539127624?_trksid=p2060353.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/1bd98be8-02f7-4c73-b2b6-70ca460efec4%40googlegroups.com.

Cri S

the orginal make difference. The motor require 75V and 6A drivers

having high inertia and is made for cnc type app, higher

holding force, high rotational inertia mass, lower speed and high weight.

2016-06-20 0:16 GMT, Mark Harris <ma...@rris.com.au>:

> http://www.omc-stepperonline.com/leadshine-dm542-digital-stepper-driver-2050-vdc-with-1042a-p-77.html

>

> Its twice the price, but worth spending the extra money on :)

>

>

>> I m buy now this stepper driver for x and y axis , I hope so that will

>> be

>> ok :

>> http://www.ebay.com/itm/191539127624?_trksid=p2060353.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

>>

>> --

>> You received this message because you are subscribed to the Google Groups

>> "OpenPnP" group.

>> To unsubscribe from this group and stop receiving emails from it, send an

>> email to openpnp+u...@googlegroups.com.

>> To post to this group, send email to ope...@googlegroups.com.

>> To view this discussion on the web visit

>> https://groups.google.com/d/msgid/openpnp/1bd98be8-02f7-4c73-b2b6-70ca460efec4%40googlegroups.com

>> .

> --

> You received this message because you are subscribed to a topic in the

> Google Groups "OpenPnP" group.

> To unsubscribe from this topic, visit

> https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

> To unsubscribe from this group and all its topics, send an email to

> To post to this group, send email to ope...@googlegroups.com.

> To view this discussion on the web visit

Михаил Юров

Henrik

Anthony Webb

Sent from my iPhone

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/be3dcd13-c17f-4b47-96ec-65cd758782a9%40googlegroups.com.

Arthur Wolf

People are quite often looking for examples of wiring.

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/be3dcd13-c17f-4b47-96ec-65cd758782a9%40googlegroups.com.

--

Jason von Nieda

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/be3dcd13-c17f-4b47-96ec-65cd758782a9%40googlegroups.com.

Henrik

Jason von Nieda

Also, check out the setup and calibration guide on the wiki.

Jason

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/5bc21831-d9c9-4ffa-aca9-eacbd3054c89%40googlegroups.com.

Henrik Olsson

Thanks Jason,

Selecting the OpenCV camera instead allowed me to get the headmounted camera going (Device ID 0) but as soon as I add the second one, setting it’s device ID to 1 and clicking [Apply] the feed for the first one freezes and I get nothing from the second (I’m guessing everything video related freezes).

Exiting OpenPnP at this point results in another BSOD, I’ve seen more of those today than I’ve had in the last 10 years J.

I’ve also tried, with only one OpenCvCamera setting, its Device ID to 1 in order to THEN add the next one with device ID 0 but as soon as I change the DeviceID and click [Apply] it crashes.

Copy pasting the <camera></camera> block in machine.xml, changing name, device index and the identifier string now results OpenPnP not starting. It does show up under processes in the task manager (using 600MB of memory) but no application on screen. Usually when I mess up the config it tells me it’s corrupt but not here.

I wanted to get video up and running so I could to do final alignment under power but this has now taken all day and part from ordering new capture devices and/or reinstalling Windows as per the old ’98 days I don’t know what to do.

Thanks!

/Henrik.

Från: ope...@googlegroups.com [mailto:ope...@googlegroups.com] För Jason von Nieda

Skickat: den 17 juli 2016 19:57

Till: OpenPnP

Ämne: Re: [OpenPnP] Re: Henriks

machine, general presentation.

Henrik, I suggest using the opencvcamera. I am mobile at the moment but can help more later. Note that you'll need to pick the deviceid on the camera config. It should be 0 and 1 for the two cams.

Also, check out the setup and calibration guide on the wiki.

Jason

.

Jason von Nieda

Jason

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/39B7C5EECE1E41F898534985C1BEE62C%40Office.

Jason von Nieda

Cri S

Install virtualdup and check if that works.

Check the opencv driver number and change I'd accordly. Don't know if that works on unmodified driver, presumably yes, but every opencv program should work. If wvm works, javafcm webcam could use that driver, but opencv can access it too, if its compiled in.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

Henrik Olsson

Hmmm, don’t know.

The Amcap application only allows me to select one or the other – which is what I’ve been trying in OpenPnP but perhaps it’s actually accessing both streams even if it’s not displaying them? Tried running two instances of Amcap but that didn’t work.

Downloaded VirtualDub, didn’t find an obvious way to show two streams at once so tried running two instances but as with Amcap only the stream selected in the first instance was working.

The capture devices are connected directly to the computer, no (external) hub.

So, these devices are unusable then – great.

Anyone know of something that actually works for what we’re doing here? I don’t care if they’re $100 each, I’m sick of messing around with crap but I suspect it’s either the $10 crap or $1000 pro gear which then isn’t DirectShow compatible and yadda yadda yadda.

The alternative is to do as SmallSMT are doing and using one capture device and switching the cameras in/out using relays (or solid state switches or whatever) but that’s yet another project and would need support from within OpenPnP….

/Henrik.

--

You received this message because you are subscribed to a topic in the Google

Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CA%2BQw0jxqVZjNf62d4CMfDW9x3Pf%2B%3D%2B%3DFstBH8%2BiE%3D8W33bMtWw%40mail.gmail.com.

Cri S

Now try open the second camera with VFW. And check if camera is switching correctly. Two cam require two digitalizer if required at same time.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/AD9E4CFEBF9643DEA139FCA5F4C31F1E%40Office.

Henrik Olsson

VFW? Video For Windows? Seems to be some sort of (old, superseeded) development framework (I’m not a software developer) so I don’t really know what I’m supposed to do with it. If that’s not it, please enlighten me.

But I tried running one instance of VirtualDub and one instance of Amcap and accessing one camera from each – no go so I’m probably dead in the water L

/Henrik.

Från:

ope...@googlegroups.com [mailto:ope...@googlegroups.com] För Cri S

Skickat: den 17

juli 2016 22:35

Till: ope...@googlegroups.com

Ämne: Re: SV: [OpenPnP] Re:

Henriks machine, general presentation.

Cri S

The problem is, this devices have one digitalizer and one MUX that must be programmed.

On newer code these MUX are depredicated, so higher end video card need VFW drivers for accessing the MUX directly.

I have asked virtualdup to know that you have installed the VFW drivers. On default no drivers is installed on win7, some video card or gaming /DVD software install it.

The hope is to use different api and that there reprogram the MUX, when switching between cams. But for that you need the list of opencv driver ports and set that number manually on opencv, because VFW is a low number and opencv use that ad default. Probably webcam is better as default. Test one cam using old VFW and the other using webcam, but is probably same as opencv and webcam at same time.

These devices are cheap. The solution is to open only the first cam and reprogramming the MUX, its a special code send with opencv but 99.999% not supported on java. If webcam and VFW works, OK otherwise buiy10$ webcam or USB video digitalizer.

--

You received this message because you are subscribed to a topic in the Google Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/749D80E0F47F4D5285CA236563C1314D%40Office.

Henrik Olsson

Ah, now I see, you mean selecting VFW as the camera type in OpenPnP, I was in “outside of OpenPnP mode” - OK.

Unfortunately, adding a camera (be it the first or the second) of type VFW camera OpenPnP just exits as soon as I click on it in the camera lis. And, as before, selecting Webcamera simply hangs OpenPnP. The only way I can get video in OpenPnP is by selecting OpenCV camera and that only works as long as one and only one camera is defined.

I definitely don’t want to replace my industrial uplooking camera with a $10 webcam but the headmounted one actually isn’t that great so…. As for buying USB digitizers – that’s what I did, right, I just didn’t realize you couldn’t use more than one of them at the same time.

Thanks!

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAJGcfUg%3DgiaV6TMtidfLrRhCtQ%3D3Uz7vEQG4Q2EKBJ%3DPbx9abQ%40mail.gmail.com.

Cri S

You definitely need to set the correct camera Id, on Google I don't find the list, I'm sending it next time I power up the PC.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/49DE4481CE504983AF13DEAFF7F4F20C%40Office.

Henrik Olsson

Thanks for all the help! You apparently know a lot of things about this stuff that I don’t and I’m not always following, unfortunately.

If you mean setting the camera ID in OpenPnP it’s when I do that that it crashes (for OpenCVCamera which is the only type I’ve been able to get ANY video thru). If you mean setting an ID when choosing VFW camera in OpenPnP then it won’t let me because as soon as I click the newly added camera in the list (in order to get to its settings on the right hand side) OpenPnP just plain exits. And when I select Webcam it crashes as soon as I try changing the “device” in the camera settings.

I think we’re all on the same page here but just so there are no misunderstandings. I’m using two cameras with composite video output, each feeding into its own USB capture device, each connected to it’s own USB-port. Two cameras, two capture devices. They look the same but they aren’t even using the same drivers and they show up under different nodes in the device manager. I’ll crack them open and see what chips they’re using.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAJGcfUigMm5_wo0zEm%3Dpk8POUhHC1_3%2B-OFOnciTy4E59nRhUw%40mail.gmail.com.

Cri S

For openpnp, select one camera on opencv, close openpnp, save copy of machine.XML . now delete camera on machine.XML.

Configure the other camera on webcam. Close openpnp.

Now copy and paste the saved camera configuration of backup openpnp camera to the machine.XML file.

Test it. Eventually invert id or camera.

Cri S

I was supposing you use one capturing device with two analog cameras.

If you use two USB capturing devices, first thing to try is not using VFW driver. Need to check if that is possible on openpnp.

Actually I'm busy , give me 20 min and I can check it.

Henrik Olsson

No, two cameras, two capture devices.

And again:

The only way I’ve ever been able to get video in OpenPnP is to select OpenCV camera, as Jason suggested, but it ONLY allows me to have ONE – not both.

Webcamera, no video, crash and BSOD when trying to select WHICH of the two devices to use.

VFWCamera, no video, instant exit as soon as the camera is selected in the list.

Will have to call it quits for today L

Från: ope...@googlegroups.com [mailto:ope...@googlegroups.com] För Cri S

Skickat: den 17 juli 2016 23:57

Till: ope...@googlegroups.com

Ämne: Re: SV: [OpenPnP] Re:

Henriks machine, general presentation.

I was

supposing you use one capturing device with two analog cameras.

Cri S

OpenPnP works settings camera id on machine.xml until you open the

config wizard.

OpenCV use that , maybe, or it use MIL , lower numbers win.

-1 = first camera found

0-99 = first 100 cameras from all drivers found, if some interface

access the same

camera, lower number wins.

Range for camera id relevant for Windows without special 3th part driver.

100 - 199 = MIL

200 - 299 = VFW

500 - 599 = QT

700 - 799 = DS

1400-1499= MMF

2016-07-17 22:06 GMT, Henrik Olsson <hen...@henriksplace.se>:

>

> And again:

>

> The only way I’ve ever been able to get video in OpenPnP is to select

> OpenCV

> camera, as Jason suggested, but it ONLY allows me to have ONE – not both.

>

> Webcamera, no video, crash and BSOD when trying to select WHICH of the two

> devices to use.

>

> VFWCamera, no video, instant exit as soon as the camera is selected in the

> list.

>

>

>

>

>

>

>

>

> _____

> Från: ope...@googlegroups.com [mailto:ope...@googlegroups.com] För Cri S

> Skickat: den 17 juli 2016 23:57

> Till: ope...@googlegroups.com

> Ämne: Re: SV: [OpenPnP] Re: Henriks machine, general presentation.

>

>

>

> I was supposing you use one capturing device with two analog cameras.

> If you use two USB capturing devices, first thing to try is not using VFW

> driver. Need to check if that is possible on openpnp.

> Actually I'm busy , give me 20 min and I can check it.

>

> You received this message because you are subscribed to a topic in the

> Google Groups "OpenPnP" group.

> To unsubscribe from this topic, visit

> https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

> To unsubscribe from this group and all its topics, send an email to

> openpnp+u...@googlegroups.com.

> To post to this group, send email to ope...@googlegroups.com.

> To view this discussion on the web visit

Jason von Nieda

--

You received this message because you are subscribed to the Google Groups "OpenPnP" group.

To unsubscribe from this group and stop receiving emails from it, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/C4CE7BDBE0E147048447244C0A390446%40Office.

Cri S

check it out using http://www.nirsoft.net/utils/usbdeview.zip and

http://www.usbman.com/WebDrivers/USBview/USBVIEW.EXE

to be sure to connect it to different usb root hubs.

On some pc, there is only one root hub. in this case, additional usb

card is needed.

Below is python code that checks first camera, then second camera, and

then both.

27 ìs the ESC key, that advance the state. It loops until it get valid

image, if you

ask why two loops. Some cameras return some invalid frame until it works.

If second is is negative, no second camera is tested.

import cv2

id1 = -1

id2 = -2

###############################

## camera 1

###############################

cam1 = cv2.VideoCapture(id1)

cam1.set(5,30) # FPS

cam1.set(15, 0.1)

while(True):

ret,frame = cam1.read()

if ret:

break

cv2.waitKey(10)

while(True):

ret,frame = cam1.read()

if ret:

cv2.imshow('cam1', frame)

if (cv2.waitKey(1) & 0xFF == 27):

break

###############################

## camera 2

###############################

if id2>=0 :

cam2 = cv2.VideoCapture(id2)

cam2.set(5,30) # FPS

cam2.set(15, 0.1)

while(True):

ret,frame = cam2.read()

if ret:

break

cv2.waitKey(10)

while(True):

ret,frame = cam2.read()

if ret:

cv2.imshow('cam2', frame)

if (cv2.waitKey(1) & 0xFF == 27):

break

###############################

## camera 1 & 2

###############################

while(True):

ret1,frame1 = cam1.read()

ret2,frame2 = cam2.read()

if ret1:

cv2.imshow('cam1', frame1)

if ret2:

cv2.imshow('cam2', frame2)

if (cv2.waitKey(1) & 0xFF == 27):

break

###############################

## release

###############################

cam2.release()

cam1.release()

cv2.destroyAllWindows()

2016-07-17 22:32 GMT, Jason von Nieda <ja...@vonnieda.org>:

>>

>> *Från:* ope...@googlegroups.com [mailto:ope...@googlegroups.com] *För

>> *Cri

>> S

>> *Skickat:* den 17 juli 2016 23:57

>>

>>

>> *Till:* ope...@googlegroups.com

>> *Ämne:* Re: SV: [OpenPnP] Re: Henriks machine, general presentation.

>>

>>

>> I was supposing you use one capturing device with two analog cameras.

>>

>> If you use two USB capturing devices, first thing to try is not using VFW

>> driver. Need to check if that is possible on openpnp.

>> Actually I'm busy , give me 20 min and I can check it.

>>

>> --

>> You received this message because you are subscribed to the Google Groups

>> "OpenPnP" group.

>> To unsubscribe from this group and stop receiving emails from it, send an

>> email to openpnp+u...@googlegroups.com.

>> To post to this group, send email to ope...@googlegroups.com.

>> To view this discussion on the web visit

>> https://groups.google.com/d/msgid/openpnp/C4CE7BDBE0E147048447244C0A390446%40Office

>> .

> --

> You received this message because you are subscribed to a topic in the

> Google Groups "OpenPnP" group.

> To unsubscribe from this topic, visit

> https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

> To unsubscribe from this group and all its topics, send an email to

> To post to this group, send email to ope...@googlegroups.com.

> To view this discussion on the web visit

Cri S

Using Id 700 or 1400 uses newer type of camera access instead of the 16bit vfw selected when using 0 , same for 1 and 701 ...

Henrik Olsson

Jason,

Don’t worry, I’m not blaiming OpenPnP J

I realise the issue exists outside of OpenPnP as well but it is a bit frustrating that it hangs, exits and crashes so vilolently, that doesn’t happen with the other apps, so it takes a lot of time trying all the various things.

I was hoping someone already knew of a capture device that worked, either multiple ones of the same or a multi channel device. A cheap 4-channel board I’ve played with before (years ago) required the use of the software that came with it. No other software could access the videostreams, same thing with a “professional” USB-camera I bought (also for this project initially) – only worked with THEIR “inspection software” so I’m a bit weary

Here’s one I’ve found:

http://www.usbgear.com/computer_cable_details.cfm?sku=USBG-4EYE&cats=125&catid=614%2C125%2C182%2C175

It clearly has 4 separate channels and it says simultaneous access to all 4 but will you be able to access them without using their specific surveillance software? I don’t expect you to provide an answer for that (but hey, if you do know then…) J

Anyway, thanks again, I’ll keep pushing.

/Henrik.

--

You received this message because you are subscribed to a topic in the Google

Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CA%2BQw0jxeQxEKo%3DY_%2BtVXdwYXYZ_iiUz6xSR03UXhCsC-sKTrbQ%40mail.gmail.com.

Henrik

Thank you Cri S, making progress (sort of) !

I moved one of the capture devices to a USB-jack on the front of the machine and I can now run two instances of Amcap and see both streams at the same time, each in its own instance of Amcap:

Unfortunately, I haven't been able to make it work in OpenPnP. It's the same issue as before. I add the first camera (OpenCV) it gets ID0, I can see the video in the window - great.

Now I add the second camera, by default it TOO gets ID0 and I have to change it to 1 in the drop down selection box but as soon as I click [Apply] it freezes, exiting OpenPnP results in an instant BSOD.

I then deleted the configuration, restarted OpenPnP, added the first camera using the GUI, then copy/paste/edited the machine.xml to add the second one. Changed the ID string, Name, Looking and the Device-ID of the second camera. This time OpenPnP started properly and video from first camera still works but I got no video on the second camera. Exiting OpenPnP resulted in another BSOD. I'm attaching my machine.xml with ONE working camera.

mojalovaa1

Henrik Olsson

Perhaps, but at this point I can see both streams, at the same time, outside of OpenPnP so it ”should” work inside OpenPnP as well.

If all else fail I’ll add a USB card but at this point I’m leaning MORE towards replacing one (or both) of the capture devices, I just don’t know with what.

/Henrik.

Från: ope...@googlegroups.com [mailto:ope...@googlegroups.com] För mojalovaa1

Skickat: den 18 juli 2016 11:55

Till: OpenPnP

Ämne: Re: [OpenPnP] Re: Henriks

machine, general presentation.

Cri.s if you remember similar problems is be on my computer because all USB is work on one router , I m add some USB card in machine and connect second camera to that usb , after that all is work .

Maybe this will help to you Henrik .

--

You received this message because you are subscribed to a topic in the Google

Groups "OpenPnP" group.

To unsubscribe from this topic, visit https://groups.google.com/d/topic/openpnp/E8rF2faOjAg/unsubscribe.

To unsubscribe from this group and all its topics, send an email to openpnp+u...@googlegroups.com.

To post to this group, send email to ope...@googlegroups.com.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/af278e81-9b99-4fd9-b71a-2606721cc11c%40googlegroups.com.

matt

sure the head is back at Z0 before any X,Y movement takes place.

Obviously I can implement this in the firmware, but I wasn't sure if

OpenPNP already supports this, I keep seeing mention of "SafeZ" and

moveToSafeZ() seems to be implemented, but wasn't sure if this does what

I want - do i just need to define safeZ to be 0 - and before any

gotoXY() type calls, if z is not 0 - then it will automatically called

moveToSafeZ(0)?

Thanks in advance

Matt

Cri S

You should check the USB root hub issue with the indicated program. Anycap is customized

and i have seen many anycap that have additional capability

Not available outside anycap.

Further you should check 700 and 1400 drivers. 700 and 701 ...

1400 1401, not 0 and 1.

The machine.XML reveal you have enabled lens correction without doing calibration. This could be blue screen reason itself. Change camera I'd to 6 .

Add second camera and set camera I'd to 5.

Then close opencv and edit the I'd . if it works, fine, otherwise install Python and opencv 2.4.x .

Web is full of how to.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/4FA69A3A5DFB4699917D55554AAF3C31%40Office.

Henrik Olsson

I have not enabled lens calibration, at least not intentionally but I’ll check that again. And if I’ve done it by mistake and it’s the cause of the BSOD then I’ve managed to enable it, by mistake, 20 times or so….

You keep saying drivers, what drivers? Are you saying I should try setting the device ID to 700/701 and 1400/1401 and 5/6 instead of 0/1 as per Jasons instructions.

I understand this is might be second nature to software developers which I’m not, I’m only a user. Have never touched Python but can follow instructions if they are written for the people that actually needs them.

Thanks again for you patience. I’ll keep messing with it as time permits.

/Henrik.

Från: ope...@googlegroups.com [mailto:ope...@googlegroups.com] För Cri S

Skickat: den 18 juli 2016 12:32

Till: ope...@googlegroups.com

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/CAJGcfUieeXrHTcO-2Zs2vXYNRE9qc1dDQOrTQBPLfq1mUeDxSw%40mail.gmail.com.

Cri S

Device I'd 5/6 is for setting it to devices without real cameras in order it don't make blue screen and let you edit machine.XML manually after closing opencv having then two configured cameras.

Opencv access cameras using drivers. There are organized on 100 blocks. Driver 200 and 201 access VfW. 0-99 is just codes that check all driver and the first that works is returned.

If you open 1, first 101 is checked, then 201, 301 ...

And you have installed VFW drivers, otherwise virtualdup don't work.

700 and 1400 driver require videolib library. I don't know if it's compiled in on openpnp opencv. Because this is possible that it don't work on openpnp and outside yes.

To view this discussion on the web visit https://groups.google.com/d/msgid/openpnp/733959F01EE44B8C827BD91D07331E47%40Office.