Serious heat issue

53 views

Skip to first unread message

Sangra69

Jun 21, 2021, 5:20:13 AM6/21/21

to DYZE DESIGN

I have been getting this serious entanglement problem within the hot end heat sink. I believe the heat is coming from the stepper motor. I wonder if this what caused my previous motor to go bad? I had it in UART mode and it worked fine for a while. Then I tried your settings with 2209's and the heat creep came back. That motor just gets way to hot.

Simon Duchaine

Jun 21, 2021, 9:41:31 AM6/21/21

to DYZE DESIGN, Sangra69

What's your motor current defined in the firmware ?

The motor needs less than 0.9 ampere.

Also, are you able to take a temperature reading of your motor ?

If your motor is too hot, you can lower the current a bit, till you get a a temp near 50C-55C.

Sangra69

Jun 22, 2021, 12:09:43 AM6/22/21

to DYZE DESIGN, Simon Duchaine, Sangra69

I got the current set to 650 from 800 in the code. Should I go lower to 400? I just don't want to skip any steps.

Sangra69

Jun 22, 2021, 12:13:06 AM6/22/21

to DYZE DESIGN, Sangra69, Simon Duchaine

This is my current code for the E0:

#if AXIS_IS_TMC(E0)

#define E0_CURRENT 450

#define E0_MICROSTEPS 16

#define E0_RSENSE 0.11

#define E0_CHAIN_POS -1

//#define E0_INTERPOLATE true

#endif

I can go lower if need be.

I can go lower if need be.

Technical Support

Jun 25, 2021, 4:20:05 PM6/25/21

to Sangra69, DYZE DESIGN

I'm wondering if the stepper driver might not be working properly. The motor manufacturer specifies a temperature rise of about 20°C when the specified current is met.

If the motor is overheating, it's highly possible that the driver is supplying more current than asked.

The motor is simply windings, so as long as they aren't melted, it should work fine.

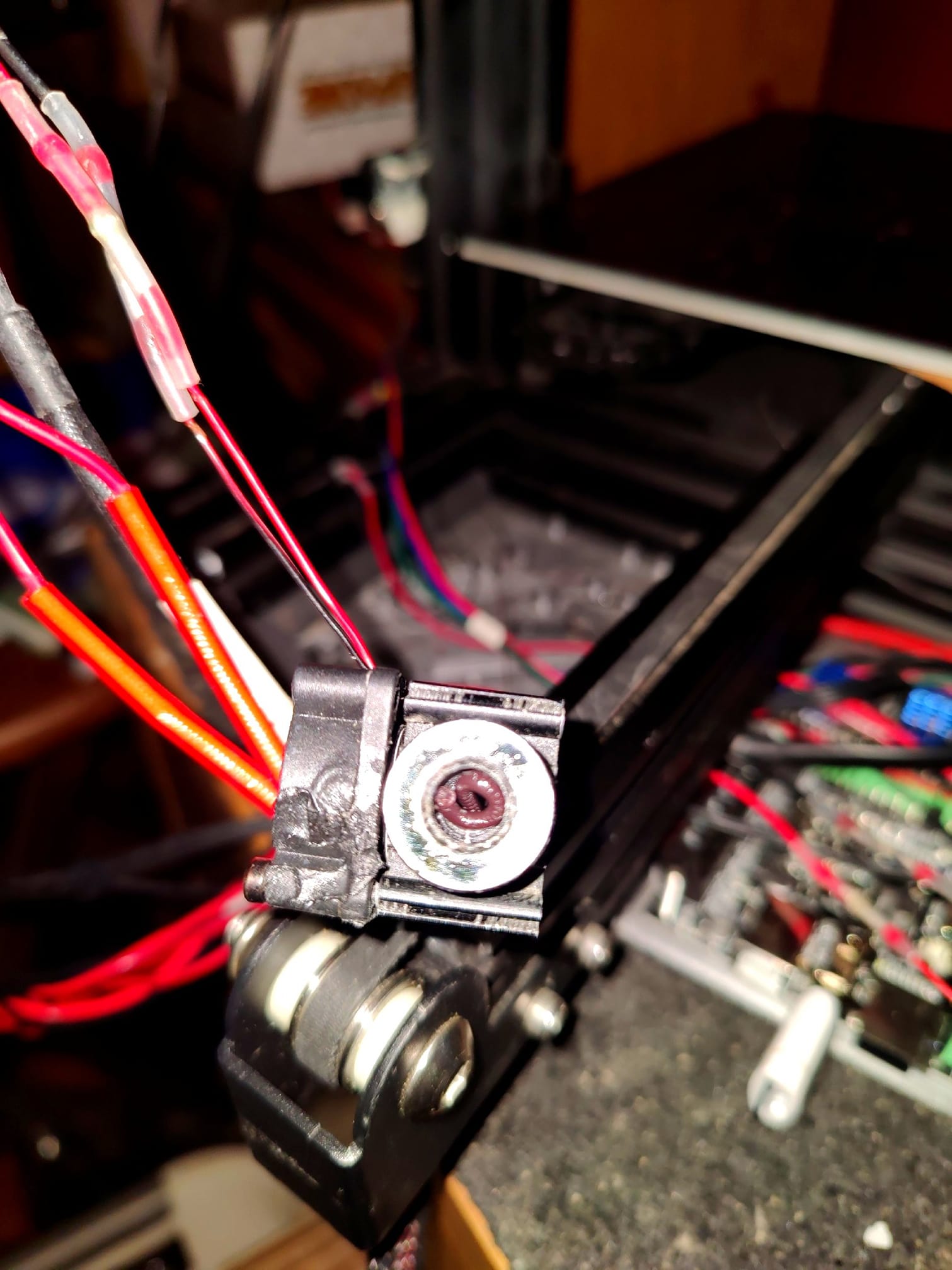

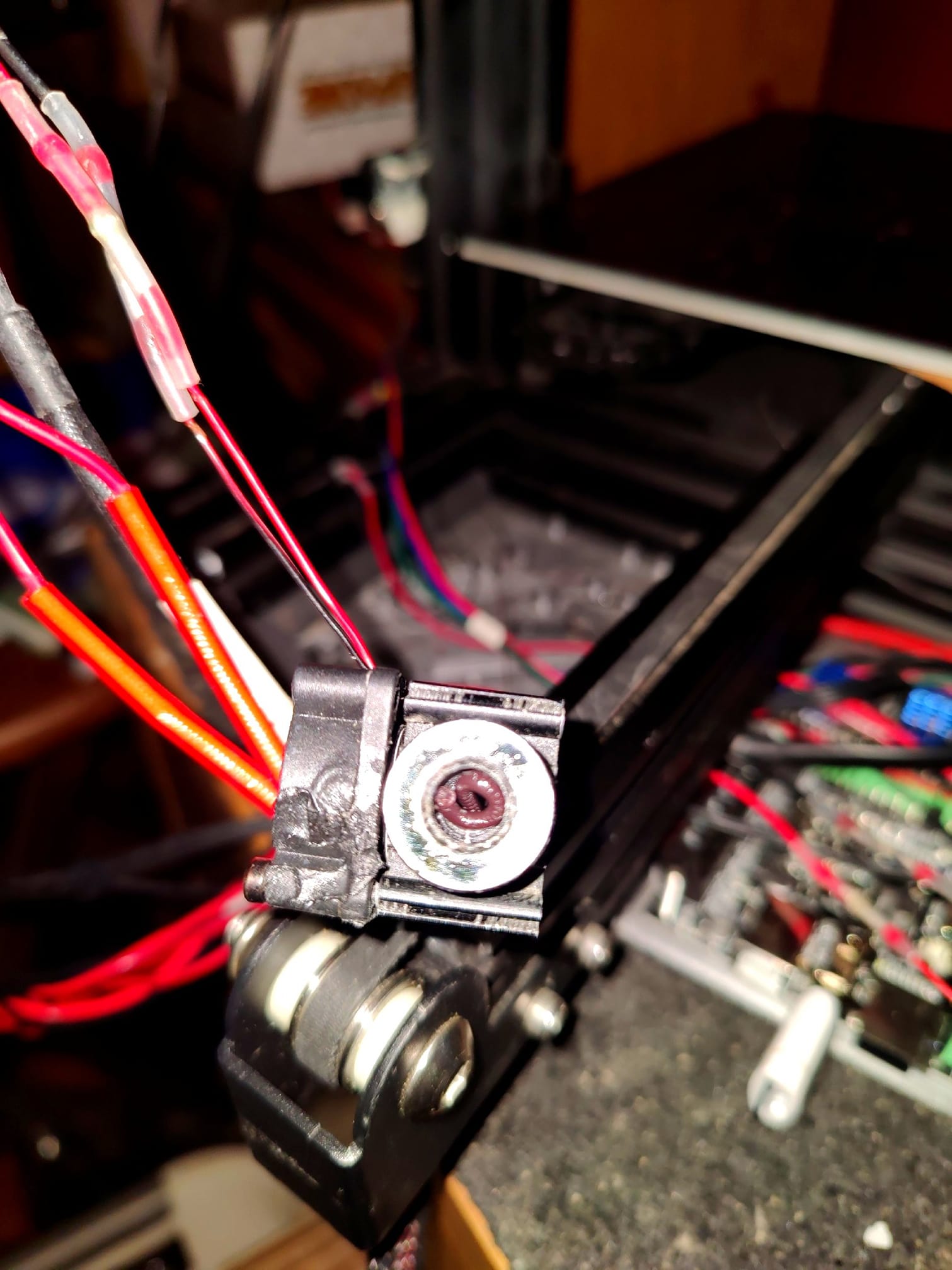

Also, by looking at the picture, I can see that the PTFE inside the hotend looks to be missing. Make sure you have the PTFE guide through the cold zone to avoid any kinks in the filament.

| Support Team |  |

| 100-1505 Saint-Thomas Lemoyne, Quebec, Canada, J4P 3S2 | |

| dyzedesign.com |

--

You received this message because you are subscribed to the Google Groups "DYZE DESIGN" group.

To unsubscribe from this group and stop receiving emails from it, send an email to support-dyze-de...@dyzedesign.com.

To view this discussion on the web visit https://groups.google.com/a/dyzedesign.com/d/msgid/support-dyze-design/72546ebe-6fea-4b56-8ce4-43e22d86d410n%40dyzedesign.com.

Patrick Emerick

Jun 25, 2021, 4:33:30 PM6/25/21

to sup...@dyzedesign.com, Sangra69, DYZE DESIGN

I had issues like this before (there is a post about it) and that 20C temperature rise is less than what I measured. I didn't have the melting like you did though. Are you running a heated bed?

To view this discussion on the web visit https://groups.google.com/a/dyzedesign.com/d/msgid/support-dyze-design/CALys2dpoZHa8F98SA9hm0mC2a8cLwFDk3NBrJMCLz5PNiXUvig%40mail.gmail.com.

Sangra69

Jun 25, 2021, 5:32:09 PM6/25/21

to DYZE DESIGN, Patrick Emerick, Sangra69, DYZE DESIGN, DYZE DESIGN

PTFE tube is there and it is metal. I never received one if it was supposed to be there. I had it working on 250 current. I can probably go lower and check to see what it can handle.

Technical Support

Jun 28, 2021, 9:50:32 AM6/28/21

to Sangra69, DYZE DESIGN, Patrick Emerick

There should be a PTFE guide through the unit like this:

If you need a replacement, please contact us though contact us page, and provide the serial number, we'll be able to assist you!

Reply all

Reply to author

Forward

0 new messages