0.4mm Tungsten Carbide Nozzle Orifice Size

24 views

Skip to first unread message

Tom Hsia

Oct 27, 2022, 12:52:01 PM10/27/22

to DYZE DESIGN

I have a rather early version of the 0.4mm tungsten carbide nozzle (2020-04-15, order number DDK-01082) and the orifice has always seemed a bit oversized when compared with other 0.4mm nozzles. I did not mind it back then because: 1)it worked so well as a 0.6mm nozzle (better than a brass 0.6mm nozzle, in fact. 2) My other 0.4mm hardened nozzles have clogged rather horribly at times.

This nozzle has performed excellently over the years and appears to have had 0 wear despite all the carbon fibre filament I pushed through it.

I wonder whether the current 0.4mm tungsten carbide still have such issues? I can't seem to the get the "contact us" page to work.

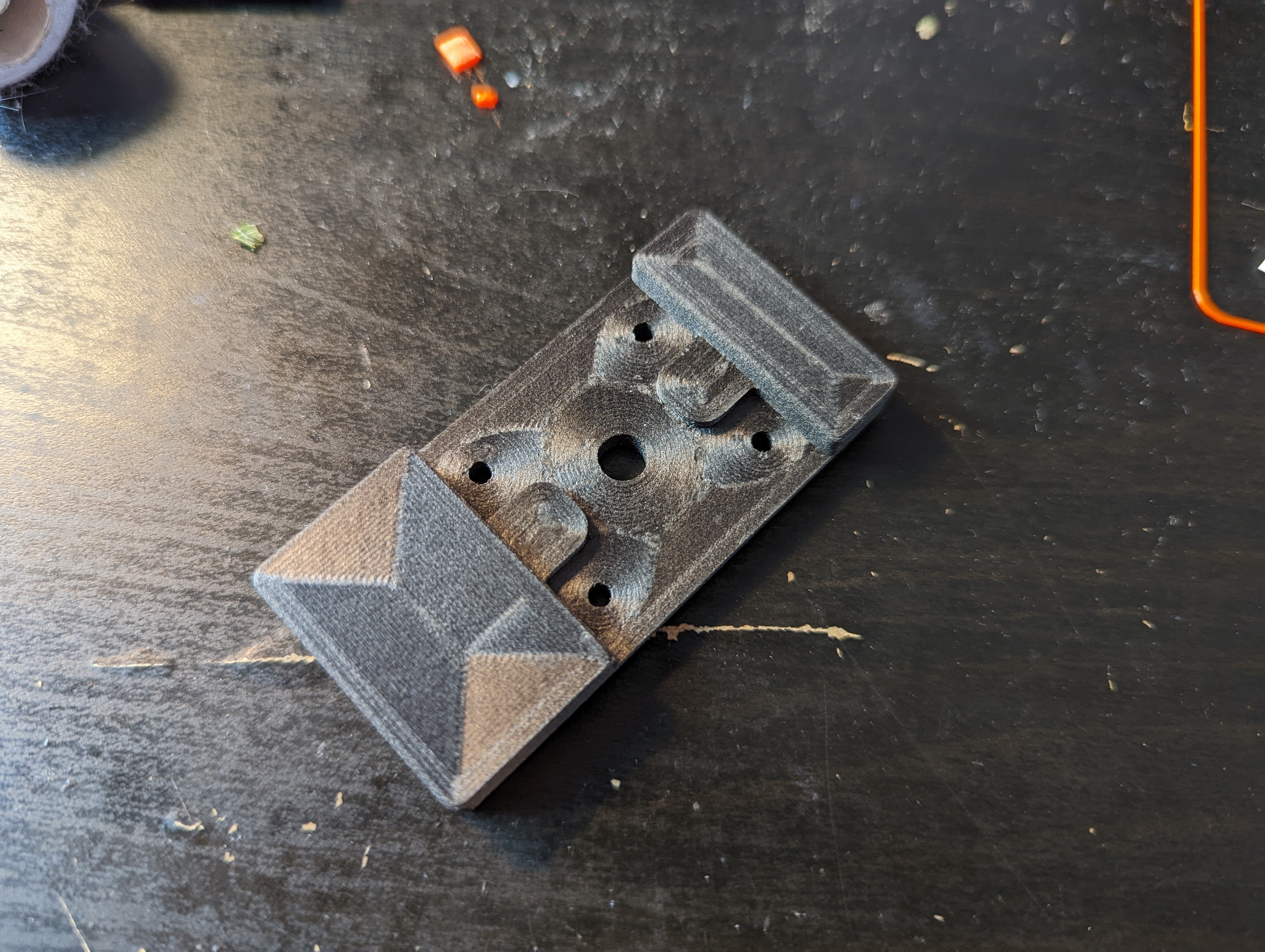

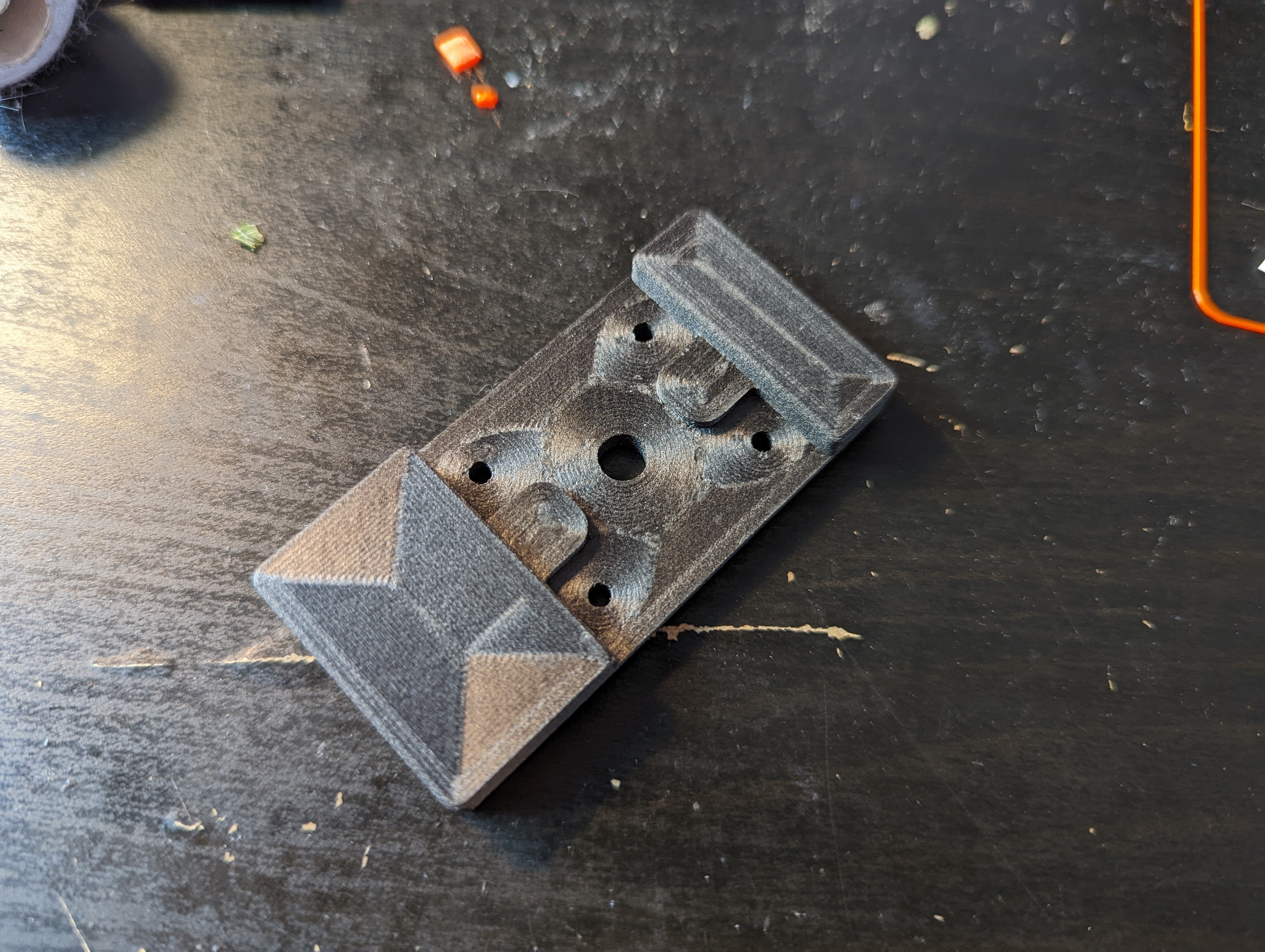

From left to right: 0.4mm E3D hardened steel, 0.4mm Dyze tungsten carbide, E3d 0.6mm plated copper.

Thanks!

Technical Support

Nov 1, 2022, 8:55:36 AM11/1/22

to 181325...@gmail.com, DYZE DESIGN

Hey Tom!

Glad to hear the Tungsten Carbide nozzle is still in great shape!

I do agree with you that the orifice looks like it's bigger than the 0.40mm.

I know that in the first batch, this hole was quite a challenge and at some point we needed to go for a different manufacturing process for the 0.40mm and the original process was not providing the quality we are looking for. The holes needed to be a little bigger than what we wanted.

If you like the quality and performance of this nozzle, I'd suggest getting a 0.60mm as the 0.40mm now is made from a different process.

--

You received this message because you are subscribed to the Google Groups "DYZE DESIGN" group.

To unsubscribe from this group and stop receiving emails from it, send an email to support-dyze-de...@dyzedesign.com.

To view this discussion on the web visit https://groups.google.com/a/dyzedesign.com/d/msgid/support-dyze-design/78bc794c-57d1-43e3-986a-4024c8ef6b43n%40dyzedesign.com.

Tom Hsia

Nov 1, 2022, 11:27:57 AM11/1/22

to DYZE DESIGN, DYZE DESIGN, DYZE DESIGN, Tom Hsia

Ah, so there was a change in manufacuring process?

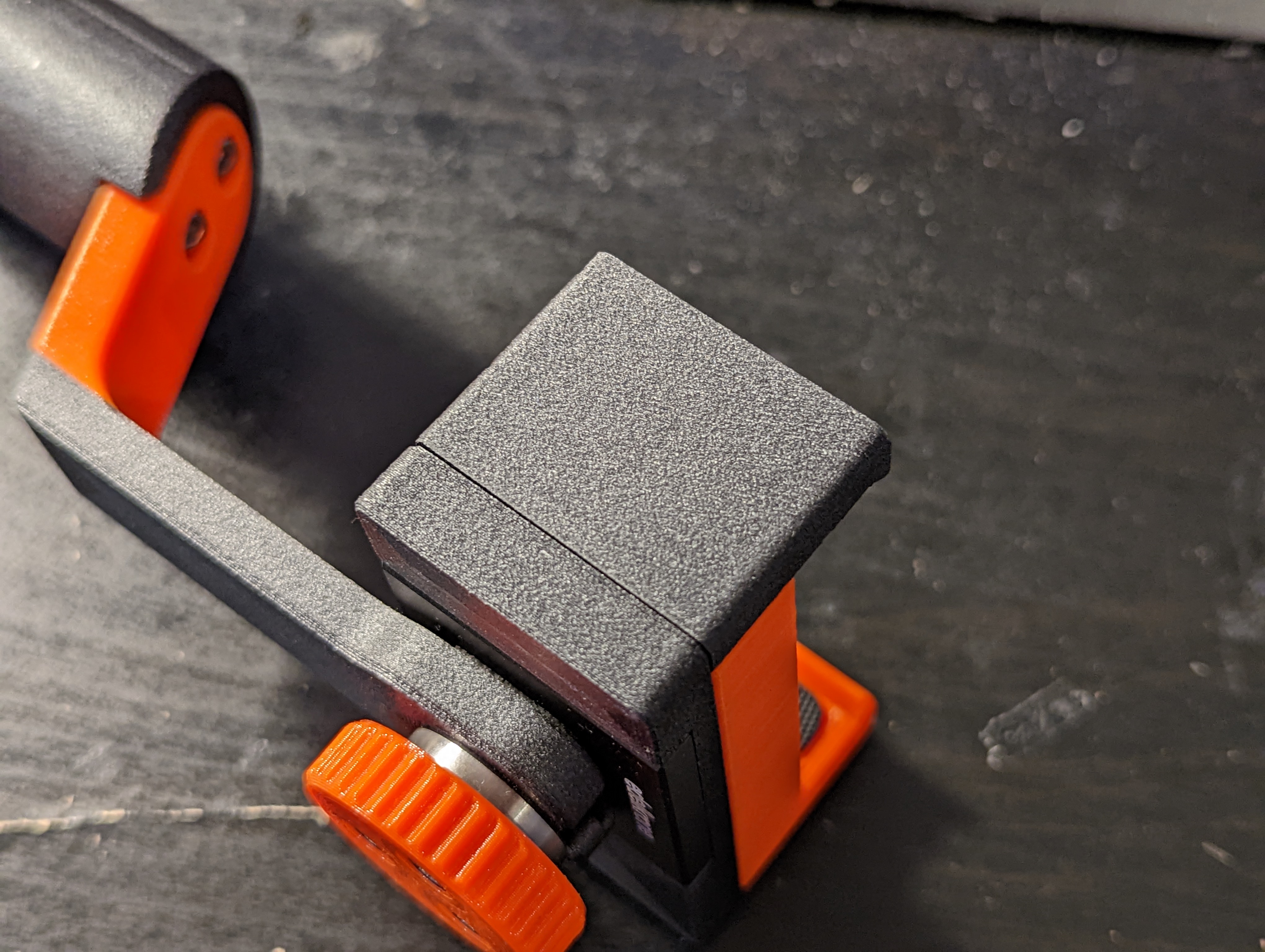

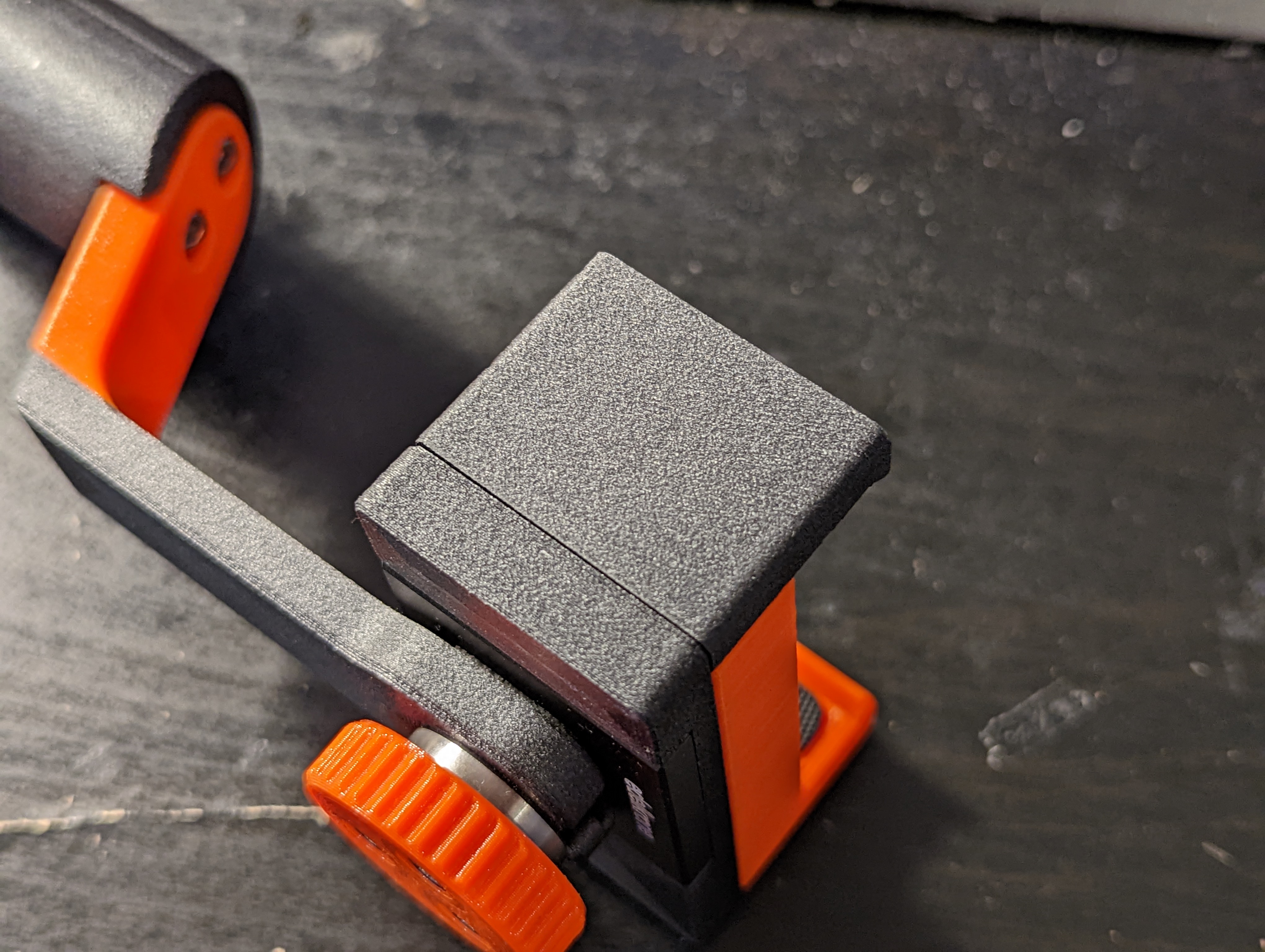

Well, if the newer batches are truly 0.4mm, I guess I'll get a new 0.4mm nozzle and use my old nozzle as a high-precision 0.6mm. My old 0.4mm Dyze nozzle is somehow my best-performing 0.6mm nozzle, it prints details slightly better than my 0.6mm copper nozzle, and has much better thermals and flow than my hardened steel ones.

Thanks.

Technical Support

Nov 2, 2022, 8:47:52 AM11/2/22

to Tom Hsia, DYZE DESIGN, DYZE DESIGN

Amazing prints Tom! Thanks for sharing them!

Reply all

Reply to author

Forward

0 new messages