Surface quality

85 views

Skip to first unread message

jonas andersen

Apr 8, 2021, 7:28:41 AM4/8/21

to DYZE DESIGN

Hi, I recently began printing using the Typhoon extruder with a 0,6mm nozzle.

.jpg?part=0.4&view=1)

I'm having a really hard time archiving a surface finish which is as good as the surface I got from my generic extruder I used before.

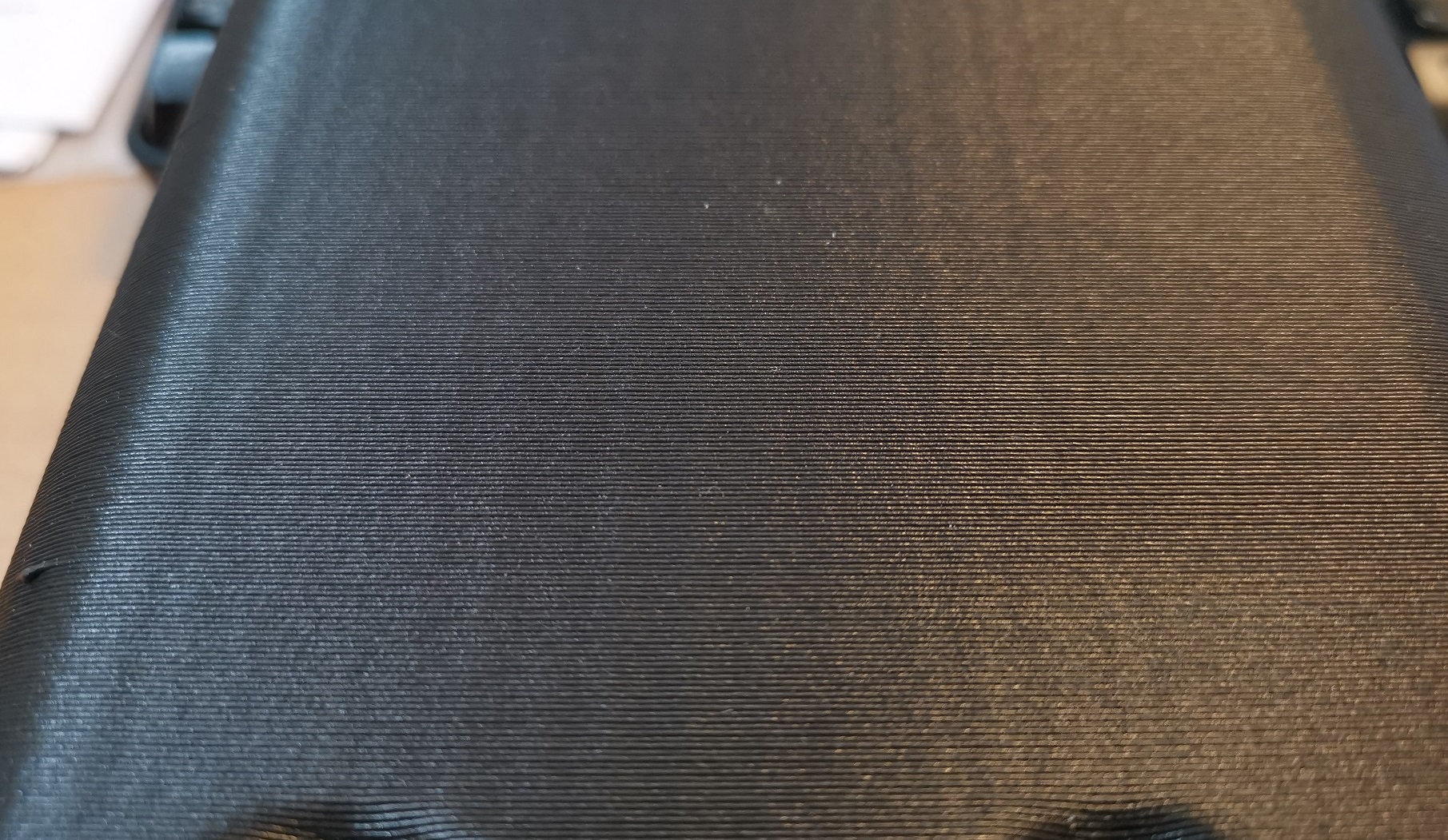

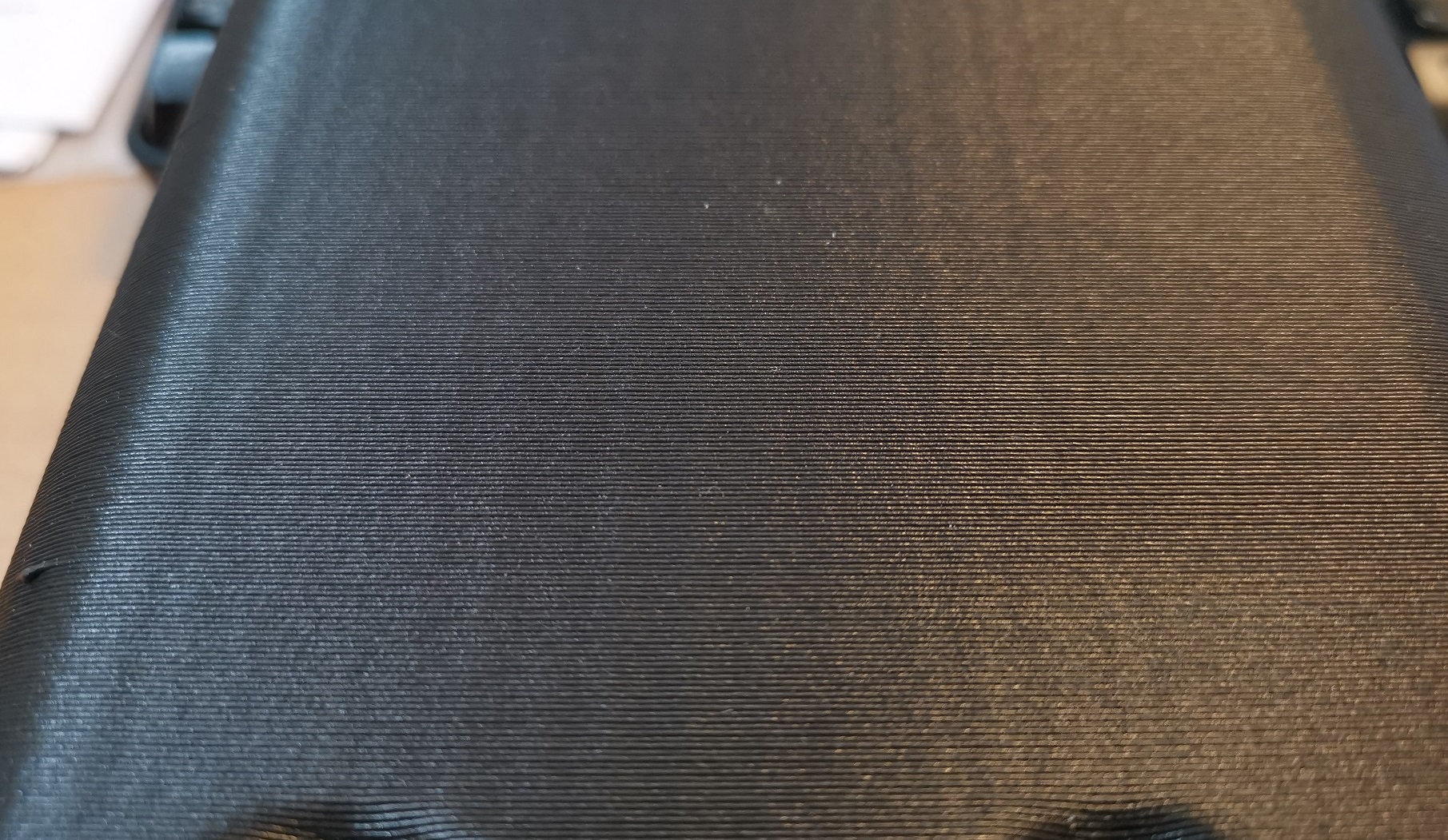

At a glace the two parts looks similar. In real life it is easy to see that the generic has more shine to it (dyze to the left - generic to the right)

Looking closer you clearly see that the generic (right) looks better than dyze (left)

.jpg?part=0.4&view=1)

This is the result from dyze. The extrusion looks uneven

The generic extruder looks very even

I have tried changing extruder speed and temperature but have not gotten close to the nice finish as seen on the generic. It is printed on the same robot using the same gcode.

My first thought was that it was overextruded but lowering the extrusion speed changed nothing. Trying to overextrude with the generic extruder does not give a similar result. The extrusion still looks much more even than on the dyze.

Do anybody have any suggestions to get a better surface or is this simply what the typhoon is capable of?

Patrick Emerick

Apr 8, 2021, 8:11:31 AM4/8/21

to DYZE DESIGN, jonasbo...@gmail.com

I don't have a Typhoon, but I have two thoughts.

1) Is your generic extruder a 2.85mm system? I have a lot of trouble with 2.85mm filament diameter inconsistency causing sporadic under/over-extrusion. Your last picture looks like what I would see with some layers looking wider than the others. Usually good 2.85mm filament is rated to the same diameter tolerance as 1.75mm, but because it's larger that tolerance can result in a more dramatic difference in the volume of the extruded line.

2) Your first picture looks like there could be a temperature difference or too much moisture in the filament. The shiny vs dull texture makes me think your generic extruder may have been extruding at a higher actual temperature or the Typhoon filament was damp and some of the heat was going to vaporizing the water instead of only melting the filament. I've found that 2.85mm filament is more difficult to dry (probably because it has a larger cross section).

jonas andersen

Apr 8, 2021, 8:47:12 AM4/8/21

to DYZE DESIGN, Patrick Emerick

No the generic extruder used 1.75mm filament. It make sense that 2.85mm has more tendency to under/over extrude if the tolerance is the same..

I did try to increase the temperature but I did not see any noticeable difference.

It might be worth looking into if a lower moisture content would change anything. I did not consider that as we have had no problems with the 1.75 filament from the same supplier.

The material we use is PBT

Thank you very much for your thoughts. It gave me something to think about.. If it is possible I could try to use 1.75 filament instead of 2.85

Patrick Emerick

Apr 8, 2021, 9:04:01 AM4/8/21

to jonas andersen, DYZE DESIGN

I've never used PBT, but I believe it is quite hygroscopic. I usually print with Nylon which loves to absorb moisture. I found that I generally needed to dry 2.85mm filament about twice as long as 1.75mm to achieve the same moisture removal percent by weight. When I get a new roll of filament I usually weigh it multiple times throughout the drying process. I call it dry when it's losing < 0.1% weight over 2 hours. Then it's stored in a 20% RH chamber which it's printed from.

If increasing temperature didn't change your results I'd attribute the dull finish to moisture and the difference in line size on the surface to filament diameter inconsistency. I built a filament diameter sensor to address that using this design: https://www.thingiverse.com/thing:4337040

Patrick Emerick

Technical Support

Apr 9, 2021, 9:15:26 AM4/9/21

to Patrick Emerick, jonas andersen, DYZE DESIGN

Thanks for your replies Patrick.

Jonas, great prints BTW.

I agree with Patrick, and would like to add more on top:

- The Typhoon has a pretty long melting zone, in order to reach high flow with bigger nozzle sizes. However, the 0.60mm nozzle isn't taking full advantage of the Typhoon, as the nozzle is quite small for the melting length, thus the polymer will stay in a heated state for a prolonged amount of time. This can lead to poor surface finish.

- Reducing the temperature could be worth a try. I had done some tests with CF filaments too and there is a temperature where the wall starts looking irregular. I ran some single wall tests squares of about 120mm in length.

- We've seen drastic finish differences when fine tuning both the flow and the line width. Some settings would lead to a wavy pattern, similar to the finish you have, then making thicker and wider lines, the pattern would stop.

| Support Team |  |

| 100-1505 Saint-Thomas Lemoyne, Quebec, Canada, J4P 3S2 | |

| dyzedesign.com |

--

You received this message because you are subscribed to the Google Groups "DYZE DESIGN" group.

To unsubscribe from this group and stop receiving emails from it, send an email to support-dyze-de...@dyzedesign.com.

To view this discussion on the web visit https://groups.google.com/a/dyzedesign.com/d/msgid/support-dyze-design/CACo%3DQ_RMgE%2BBA8gujsjJX_rEYoquDve8Q%2BQfLyz%3DMrXPnGnvjg%40mail.gmail.com.

Ronnie Parsons

Aug 12, 2021, 3:27:24 PM8/12/21

to DYZE DESIGN, jonasbo...@gmail.com

Hi Jonas,

We are currently looking spec'ing out a robotic FGF set up for 3d printing purposes. I was wondering if you have a similar setup? I look forward to your response.

Reply all

Reply to author

Forward

0 new messages