ARC Newsletter August 12, 2020

Aprovecho Research Center

76132 Blue Mountain School Road, PO Box 1175

Cottage Grove, Oregon, 97424 - USA

With 6mm Channel Gap Adjustable Pot Skirt

The Jet-Flame in the CQC Rocket Stove with its 6mm Channel Gap Adjustable Pot Skirt

Starting in 2004, Aprovecho was hired by the Shell Foundation to adapt the Rocket stove in southern India. For the first time, ARC was hired as part of a project in which the reduction of harmful emissions was a major motivation. The effort was called the Breathing Space Program. Unfortunately, while generally liked by cooks, the insulated Rocket did not reduce PM2.5 enough to protect health. In African field tests, the insulated Rocket reduced emissions of PM2.5 by about 40% (USAID, 2008, 2010). The stove needed higher temperatures and more mixing!

During the 2013-2015 DOE research and development project, air jets were installed in the floor of the combustion chamber in a Rocket stove resulting in dramatically reduced PM2.5 emissions. In 2018, ARC was hired by the Gates funded Global Health Labs tasked to co-innovate solutions to integrate fan-driven jets of air into a Rocket stove. The SSM Jet-Flame combustion chamber accessory was the result. See: www.Jet-Flame.com

A stove accessory that slides into a combustion chamber can be used in an open fire, clay/sand stoves, in Rocket stoves, etc. An add-on product is less expensive and fits into multiple applications. Hundreds of tests (that are ongoing) at the ARC lab reveal that ‘bottom air jets’ work to reduce emissions by super-heating the charcoal bed, helping the sticks to burn hotter, and by creating turbulence in and above the fire. The higher temperatures (over 900C at the bottom of the pot and around 1,100C in the fire) and increased gas velocity were seen to also improve heat transfer efficiency.

The Jet-Flame prototypes were field tested in Kenya so that cooks could help to design the final product. More than 100 samples have been distributed worldwide with support from Global Health Labs. There are currently five field test reports from Africa, Asia, and Central America. CQC has begun a large scale project in Malawi.

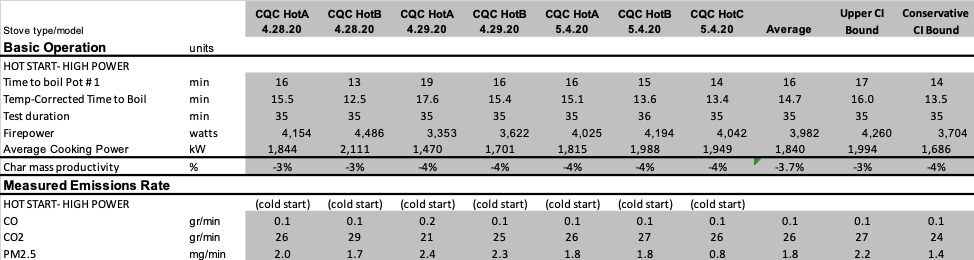

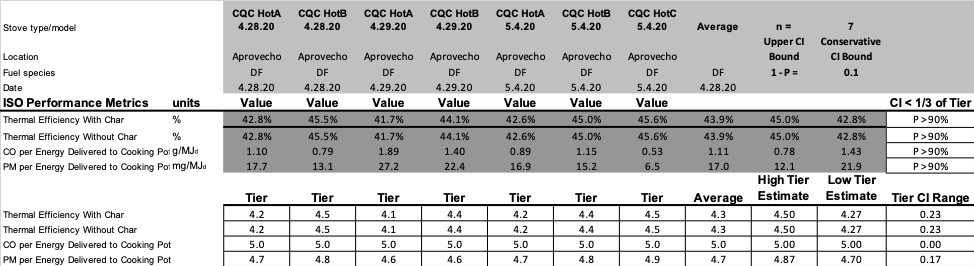

ARC is continuing to study the Jet-Flame and we are learning a lot about the relationship of temperature, excess air, rate of reactions, mixing, and residence time to the emission factors of CO and PM2.5. The following hot start test results at high power show the performance of the stove in the context of the ISO 19867-3 Voluntary Tiers of Performance. The 90 % confidence interval for each metric is within 1/3 of the distance between the Tiers. Follow the link below to see the results for medium and low power.

Aprovecho Research Center

76132 Blue Mountain School Road, PO Box 1175

Cottage Grove, Oregon, 97424 - USA

What’s New at ARC?

One of the great things about working at ARC is that we sometimes get to carve out exactly what we want to accomplish in the next quarter. And there is a certain kind of rural freedom especially during a pandemic that includes rivers and lakes. At a recent planning meeting, we decided to accomplish the following by ETHOS:

Dean Still will finish the 2nd edition of Clean Burning Cook Stoves with new chapters covering what we have learned in the last five years. He’s also working with Liberator in Missouri to make a forced draft Rocket heating stove to be introduced at ETHOS and assisting SSM to design a one liter, vacuum insulated solar pasteurizer based on affordable double walled drinking bottles made in China.

Sam Bentson is finishing up another summer long experiment with the interns from Oregon State University defining how to reduce exposure to smoke in the Test Kitchen with PM sensors tracking concentrations. How much safer is it to cook outdoors? Sam will tell you in two weeks! The students are also making progress on a robot to replace the human fire operator in ISO stove testing. The LEMS continues to be a valuable resource for cookstove laboratories around the world. The most recent installation included a PEMS with a newly developed portable gravimetric system.

David Evitt has installed oxygen, velocity, and temperature sensors in the EPA SBIR testing set up under the LEMS and is optimizing the Jet-Flame, learning how many standard liters of air best reduce PM2.5 at varying fire powers. He is also able to track excess air and air/fuel ratios with combustion chamber temperatures being shown again to play a determining role in increased combustion efficiency. We expect that by ETHOS (third weekend in January) a lot more will be known about not just the Jet-Flame but combustion in general.

Great way to spend a summer!